As one of the internationally recognized general-purpose hot work die steels, AISI H13 steel achieves a good balance between high-temperature strength, toughness, and resistance to thermal fatigue.

With its excellent machinability, appropriate heat treatment, and surface treatment, AISI H13 steel can fully unleash its properties and significantly extend the service life of dies.

AISI H13 steel is widely used in high-temperature processes such as die casting, hot extrusion, and hot forging, making it one of the preferred materials for dies subjected to high temperatures, high stress, and thermal cycling loads.

CHEMICAL COMPOSITION:AISI H13 & EQUIVALENT GRADE

| Standard | Grade | C | Si | Mn | P | S | Cr | Mo | V |

| ASTM A681 | H13 | 0.32-0.45 | 0.8-1.2 | 0.2-0.5 | 0.03 | 0.03 | 4.75-5.5 | 1.1-1.75 | 0.8-1.2 |

| DIN ISO 4957 | 1.2344 | 0.37-0.42 | 0.9-1.2 | 0.3-0.5 | 0.03 | 0.03 | 4.8-5.5 | 1.2-1.5 | 0.9-1.1 |

| GB/T 1299 | 4Cr5MoSiV1 | 0.32-0.42 | 0.8-1.2 | 0.2-0.5 | 0.03 | 0.03 | 4.75-5.5 | 1.1-1.75 | 0.8-1.2 |

| JIS G4404 | SKD61 | 0.35-0.42 | 0.8-1.2 | 0.25-0.5 | 0.03 | 0.03 | 4.8-5.5 | 1.0-1.5 | 0.8-1.15 |

AISI H13 STEEL PHYSICAL PROPERTY

- Density: 7.85 g/cm³

- Melting point: 1430-1470℃

- Thermal conductivity: Approx 26 W/(m・K) (20℃)

- Linear expansion coefficient: 11.5 × 10⁻⁶/℃ (20-600℃)

AISI H13 STEEL FORGING

The core of AISI H13 steel forging: breaking up coarse carbides in the as-cast structure, refining the grains, and eliminating internal defects.

Forging of AISI H13 steel is a crucial step in its manufacturing process; its quality determines the subsequent heat treatment performance and the final service life.Therefore, strict control of its forging process is particularly important.

First, the standardization of heating must be strictly followed. Before forging, the temperature can be slowly and fully preheated to 650-750°C.The initial forging temperature of AISI H13 steel should be between 1050℃ and 1150℃, and the final forging temperature must be strictly controlled above 850℃. Below this temperature, the plasticity decreases sharply, and continued forging will easily lead to cracks.

During forging, deformation should proceed slowly, and the repeated upsetting-drawing process effectively breaks down large carbides and ensures uniform distribution.For general requirements, the forging ratio should be ≥4:1. For important parts such as mold cavities, the forging ratio should reach ≥5:1.

Direct air cooling after forging is strictly prohibited; sand cooling or furnace cooling are recommended.

For AISI H13 steel, forging gives it endless possibilities.

AISI H13 STEEL HEAT TREATMENT

Heat treatment is the core process that determines the final properties of AISI H13 steel. Therefore, it must be precisely controlled to achieve excellent high-temperature strength, toughness, thermal fatigue resistance, and wear resistance.

The main processes include preheating (annealing) and final heat treatment (quenching + tempering), and surface strengthening treatments can be performed as needed.

Preliminary Heat Treatment: Spheroidizing Annealing

The core purpose of AISI H13 spheroidizing annealing is to transform coarse, lamellar carbides into uniform, fine spherical carbides, which are then dispersed throughout the ferrite matrix.

AISI H13 steel is mainly annealed by isothermal spheroidizing in industry, with an annealing temperature of 840-870°C. After appropriate holding, temperature should be rapidly cooled to 720-740°C for long-term isothermal treatment, and then air-cooled after furnace cooling to below 500°C.

The quality of spheroidizing annealing directly determines the effects of subsequent processing and final heat treatment. Therefore, the spheroidizing annealing effect of AISI H13 steel should achieve a hardness of 180-229 HBW and a spheroidization grade of 2-4.

Final Heat Treatment: Quenching & Tempering

The core of the final heat treatment of H13 steel is “quenching + multiple high-temperature tempering“, which ultimately achieves uniform hardness, a good balance of strength and toughness, excellent resistance to thermal fatigue, and high-temperature strength (red hardness).

The quenching temperature of AISI H13 steel is 1020~1050℃. After complete austenitization, it can be rapidly cooled by oil cooling/air cooling to obtain a martensitic structure with high strength and hardness.

To eliminate quenching stress and improve red hardness and toughness, AISI H13 steel requires 2-3 high-temperature tempering cycles at 540-650℃. Multiple tempering cycles ensure that the final microstructure consists of “tempered martensite + dispersed fine alloy carbides,” resulting in greater stability and superior performance.

AISI H13+QT Steel Mechanical Property

| Tensile Strength | Yield Strength,20°C | Yield Strength,600°C | Elongation | Impact Charpy-V,20°C | Hardness |

| 1500-1700 Mpa | 1200-1400Mpa | ≥1000Mpa | 8-12% | 15-30J | 48-52HRC |

Surface Strengthening Treatment

Surface strengthening treatment of H13 steel primarily targets surface failure modes such as wear, oxidation corrosion, thermal fatigue cracking, and molten metal adhesion.

In short, after the overall “quenching and tempering” (ensuring core strength and toughness), special processes (such as nitriding and PVD coating) are used to treat the surface of the H13 mold, forming a high-hardness, highly wear-resistant surface layer, achieving “hard exterior and tough interior,” which is one of the most economical and effective treatments of extending mold life.

H13 STEEL MAIN APPLICATION

H13 steel, with its excellent high-temperature strength, wear resistance, thermal fatigue resistance, and moderate toughness, mainly serves the “hot working” field and is widely used in various molds that need to work in high-temperature, high-pressure, and high-wear environments, making it the well-deserved “king of hot work die steels”.

- Die casting mold: This is the main application area of H13 steel, especially for key components such as core, cavity, slider, ejector pin, etc. of aluminum alloy, magnesium alloy, zinc alloy die casting mold. It has good resistance to erosion and thermal fatigue of molten metal.

- Hot forging mold: used for forging hammer forging die, press forging die, forging press die (such as connecting rod, crankshaft, gear forging die, etc.), bearing impact load and high temperature.

- Hot extrusion mold: used for extrusion cylinder, extrusion rod, extrusion die (die pad, die core, die sleeve) of metals such as aluminum, copper, brass, and steel.

- Plastic mold: H13 is also a common choice for high-performance plastic molds (such as engineering plastics, injection molds containing abrasive fillers) that require high wear resistance, high polishing and good corrosion resistance.

| Tempering Temperature | Typical Hardness | Applicable Scenarios |

| 540-560°C | 50-52HRC | High wear resistance requirements (before surface treatment) |

| 580-600°C | 48-50HRC | Best comprehensive performance (die casting mold/hot forging mold) |

| 620-650°C | 44-46HRC | High toughness requirements (such as impact forging mold) |

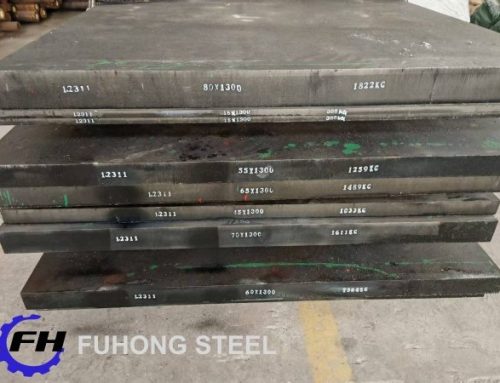

AISI H13 STEEL SUPPLY FORM & SIZE & TOLERANCE

Round bar:Φ12-Φ1000mm

Flat bar:Thickness :8-600mm ,Width:200-1100mm

| Surface Finish | Black-Forged | Black-Rolled | Rough Turned | Cold Drawn | Peeled | Polished | Grinded |

| Tolerance | 0/+5mm | 0/+1mm | 0/+3mm | Best H11 | Best H9 | Best H9 | Best h8 |