DIN1.2329 steel Manufacturer and Exporter,supplied with round,square,flat,block,and shaft etc.

Din 1.2329 steel,also refers to 46CrSiMoV7 as per German standard.As one of thehot work tool steels,Din 1.2329 steel has high strength and good toughness at high temperature,as well as excellent heat fatigue resistance and tempering resistance.

In addition to these, it also has good processing and use properties, such as welding, nitriding, and machinability.Din 1.2329 steel is usually delivered in annealed condition.

DIN 1.2329/46CrSiMoV7 STEEL SUPPLY FORM & SIZE & TOLERANCE

Hot Forged Round bar:Φ80-Φ1000mm

Hot Rolled Round bar:Φ16-Φ130mm

Hot Forged Square bar: Max Thickness:500mm

Flat bar/Blcoks:Thickness :120-800mm ,Width:120-1500mm

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |

DIN 1.2329/46CrSiMoV7 STEEL CHEMICAL COMPOSITION

| Grade | C | Si | Mn | P | S | Cr | Mo | Ni | V |

| 1.2329 | 0.43-0.48 | 0.6-0.75 | 0.65-0.85 | ≤ 0.025 | ≤ 0.025 | 1.65-1.85 | 0.25-0.35 | 0.45-0.6 | 0.17-0.22 |

| Residual element requirements:Cu≤ 0.3,W≤ 0.2,Co≤ 0.2,Al≤ 0.03 | |||||||||

DIN 1.2329 STEEL FORGING

- Initial Forging Temperature:1100℃

- Final Forging Temperature:900℃

- Forging Ratio:above 4:1

- Cooling Method After Forged:As a white-spot sensitive steel, the recommended method for DIN 1.2329 steel after forging is annealing and hydrogen elimination treatment

DIN 1.2329 STEEL NON-METALLIC INCLUSION REQUIREMENTS

- ASTM E45(method A)

| A | B | C | D | ||||

| Fine | Coarse | Fine | Coarse | Fine | Coarse | Fine | Coarse |

| Max 1.5 | Max 1.0 | Max 1.5 | Max 1.0 | Max 1.5 | Max 1.0 | Max 2.0 | Max 1.5 |

- DIN 50602

K4≤20

DIN 1.2329/46CrSiMoV7 STEEL HEAT TREATMENT

- Soft Annealing

The softening annealing temperature of DIN 1.2329 steel is controlled at 780-800℃,and after sufficient holding time, it will be cooled with the furnace.The Annealing Hardness will be below 230HBW.

DIN 1.2329 Steel Mechanical Property in actual production with Annealing condition

| Tensile Strength,Mpa | Yield Strength,Mpa | Elongation,% | Charpy Impact, J | Hardness,HBW |

| 730 | 440 | 26 | 36/30/28 | 170-220 |

- Quenching & Tempering

Quenching Temperature:880-920℃

Quenching Medium:oil, polymer or salt bath

Quenching Hardness:53-55HRC

Tempering Temperature:200-250℃ Followed by Quenching

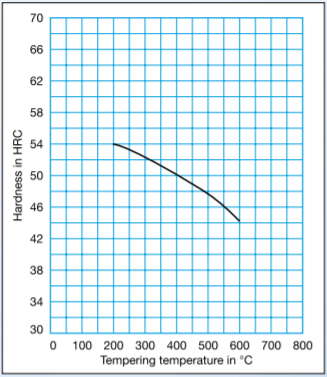

DIN 1.2329 Steel Tempering vs Hardness Diagram

DIN 1.2329 Steel Mechanical Property in actual production with Quenched&Tempered condition

| Tensile Strength,Mpa | Yield Strength,Mpa | Elongation,% | Contraction,% | Charpy Impact, J |

| 1350 | 1080 | 14 | 40 | 7/8/8 |

DIN 1.2329/46CrSiMoV7 STEEL APPLICATIONS

As Hot work tool steel,DIN 1.2329 has good mechanical characteristics in hot and cold condition,and suitable for welding operations.

It is widely used for forging dies, pressure disks for extrusion, mould press dies, and many other applications.