DIN 1.2083/X40Cr14 Steel is not only the Cr series of German plastic mold steel, but also one of the representative steel grades of martensitic stainless steel, especially its Cr content is as high as 13%.DIN 1.2083 steel has excellent wear resistance, good acid resistance, good polishing performance, and good workability.

After quenching, it is more wear-resistant, not only suitable for electro-erosion operation, but also suitable for acidic plastics and molds that require good polishing.

DIN1.2083 steel ingots are usually smelted with ESR technology, and the products are usually delivered in an annealed condition.

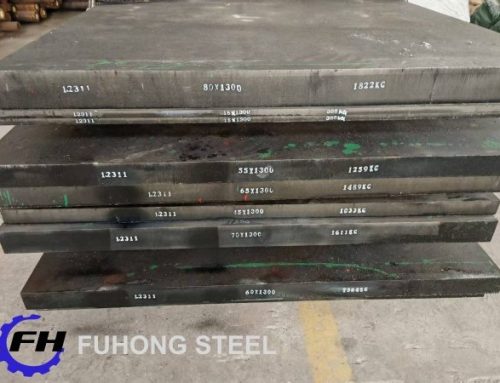

DIN 1.2083 STEEL SUPPLY FORM & SIZE & TOLERANCE

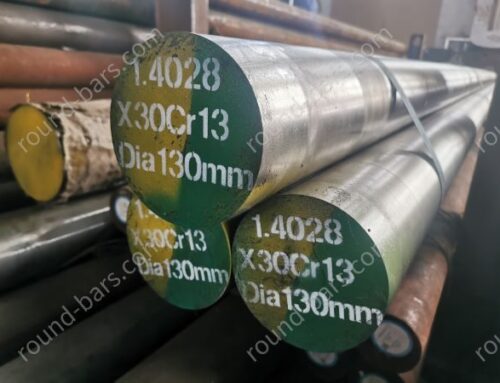

Hot Forged Round bar:Φ80-Φ1000mm

Hot Rolled Round bar:Φ16-Φ130mm

Hot Forged Square bar: Max Thickness:500mm

Flat bar/Blcoks:Thickness :120-800mm ,Width:120-1500mm

| Surface Finish | Black-Forged | Black-Rolled | Rough Turned | Cold Drawn | Peeled | Polished | Grinded |

| Tolerance | 0/+5mm | 0/+1mm | 0/+3mm | Best H11 | Best H9 | Best H9 | Best h8 |

DIN 1.2083 STEEL CHEMICAL COMPOSITION

| Grade | C | Si | Mn | P | S | Cr |

| 1.2083 | 0.36-0.42 | ≤1.0 | ≤1.0 | ≤ 0.03 | ≤ 0.03 | 12.5-14.5 |

DIN 1.2083 STEEL EQUIVALENT GRADE

China/GB 20878:40Cr13

USA/ASTM A681:420

Japan/JIS G4403:SUS420J2

DIN 1.2083 STEEL FORGING

- Initial Forging Temperature:1150℃

- Final Forging Temperature:750℃

- Forging Ratio:above 4:1

- Cooling Method After Forged: Furnace Cooling

DIN 1.2083 STEEL MAIN PERFORMANCE CHARACTERISTICS

- Good Corrosion Resistance & Wear Resistance & Machinability

- Good Hardenability

- Low Deformation Rate

- Excellent Polishability in hardened condition

- High Surface Accuracy

- The original high precision can still be maintained after long-term production

- Very low inclusion content

- Low maintenance cost

- Stable production cycle

DIN 1.2083 STEEL PHYSICAL PROPERTY

| Density, g/cm3 | 7.75 | |

| Specific heat capacity,(0~100℃),kj/(kg.k) | 0.46 | |

Thermal conductivity W/(m.K) | 100℃ | 500℃ |

| 28.1 | 28.9 | |

Linear expansion coefficient,10^-6/k | 0~100℃ | 0~500℃ |

| 10.5 | 12 | |

| Resistivity(20℃),Ω.mm2/m | 0.59 | |

| Longitudinal modulus of elasticity (20℃),kN/mm2 | 215 | |

| Magnetic | Magnetic | |

DIN 1.2083 STEEL HEAT TREATMENT

- Annealing

The general annealing temperature is 780-800℃ with heat preservation 4-6 hours.With cooling ratw below50℃/h, cooled to 550℃,then air-cooling.

Isothermal annealing adopts temperature 700-800℃ to keep for 2-4 hours, and then 670-720℃ to keep for 2-4 hours, cooling at a cooling rate of ≤50℃/h to 500℃, finally air cooling.

The Annealing Hardness will be below 241HBW.

- Quenching & Tempering

Quenching Temperature:1000-1100℃

Quenching Medium:Oil

Quenching Hardness:50HRC

Tempering Temperature:200-300℃,Cooling in still air

Metallographic structure:martensite

DIN 1.2083 STEEL APPLICATIONS

As a martensitic stainless steel, DIN 1.2083 steel is mainly used to make surgical medical appliances, bearings, valves, springs and high-strength molds due to its excellent performance.