AISI 4340 is defined as medium-carbon nickel-chromium-molybdenum alloy structural steel in the AISI/ASTM standard system.

AISI 4340 steel is renowned for its superior strength-toughness balance and high hardenability. Through quenching and tempering heat treatment, 4340 steel can achieve tensile strengths exceeding 1000 MPa while maintaining excellent impact toughness and fatigue resistance.

As a guarantee of high reliability,AISI 4340 steel can meet the most demanding application requirements in aerospace,automotive,and machinery industries.

AISI 4340 STEEL & EQUIVALENT GRADE CHEMICAL COMPOSITION

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo |

| 4340 | 0.38-0.43 | 0.15-0.35 | 0.6-0.8 | ≤0.035 | ≤0.04 | 0.7-0.9 | 1.65-2.0 | 0.2-0.3 |

| 40CrNiMoA | 0.37-0.44 | 0.17-0.37 | 0.5-0.8 | ≤0.025 | ≤0.025 | 0.6-0.9 | 1.25-1.65 | 0.15-0.25 |

| 36CrNiMo4 | 0.32-0.4 | ≤0.4 | 0.5-0.8 | ≤0.035 | ≤0.035 | 0.9-1.2 | 0.90-1.2 | 0.15-0.3 |

| EN24/817M40 | 0.36-0.44 | 0.1-0.4 | 0.45-0.7 | ≤0.035 | ≤0.04 | 1.0-1.4 | 1.3-1.7 | 0.2-0.35 |

| SNCM439 | 0.36-0.43 | 0.15-0.35 | 0.6-0.9 | ≤0.03 | ≤0.03 | 0.6-1.0 | 1.6-2.0 | 0.15-0.3 |

AISI 4340 STEEL PHYSICAL PROPERTY

- Density: 7.85 g/cm³

- Melting point: approx. 1427°C

- Elastic modulus: approx. 200-210GPa

- Poisson’s ratio: 0.27-0.30

- Thermal conductivity (20℃): 42 W/(m・K)

- Specific heat capacity (20℃): 460 J/(kg・K)

- Linear expansion coefficient (20~100℃): 11.3×10⁻⁶/℃

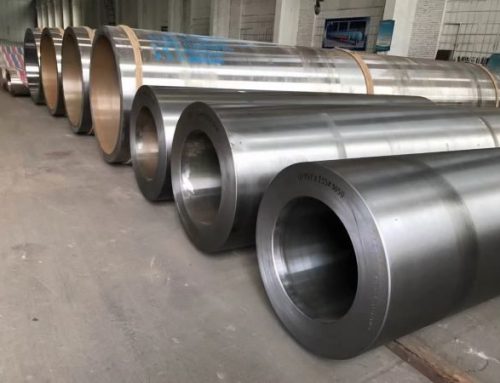

AISI 4340 STEEL FORGING

The core principles of forging AISI 4340 steel are: uniform heating, full deformation, slow cooling, and stress relief.

Due to the poor thermal conductivity of AISI 4340 steel, in order to avoid the risk of thermal stress cracking, stepped preheating (650~800℃) before forging can gradually and evenly increase the overall temperature.Initial forging temperature should be carried out between 1150℃-1200℃,and final forging temperature should be strictly controlled between 850-900°C.

During forging, multiple small deformations are performed to ensure that the core of the 4340 steel is fully deformed.To eliminate the original casting defects of 4340 steel, the forging ratio should be at least 4:1.

After forging, 4340 steel must be slowly cooled. For general forgings, direct furnace cooling is acceptable. However, for large or complex forgings, isothermal annealing is necessary to relieve internal stress.

For 4340 steel, forging is only the first step in obtaining its shape and preliminary microstructure. Subsequent heat treatment is what gives its superior properties.

AISI 4340 STEEL HEAT TREATMENT

Heat treatment is the “soul” of AISI 4340 steel’s performance. The core heat treatment process is quenching and tempering, supplemented by pre-treatment (annealing/normalizing) to eliminate defects from previous processes.

- AISI 4340 Steel Preliminary Heat Treatment

The core of pre-heat treatment for 4340 steel is to eliminate residual stress from previous processes, refine grain size, and improve machinability, providing an ideal homogeneous microstructure for subsequent core quenching and tempering treatments. There are two main processes: Normalizing and Annealing.

The main purpose of normalizing 4340 steel is to refine the grains and optimize the microstructure. The normalizing temperature should be controlled at 880-900℃, and the steel should be held at that temperature for a sufficient time before air cooling.

Annealing 4340 steel focuses on softening the material and relieving internal stress. Annealing can be further divided into many processes, among which isothermal annealing achieves the best results.The annealing temperature is 830-860°C, held at that temperature, then rapidly cooled to 650-700°C, held at that temperature for a long time isothermally, and then cooled in the furnace to below 500°C before air cooling.

Both of the above processes can be considered as qualified and effective preparatory processes before the final heat treatment.

- AISI 4340 Steel Final Heat Treatment:Quenching & Tempering

“Quenching + high-temperature tempering” is the core process that gives 4340 steel its superior properties. Through this process, 4340 steel can obtain a tempered sorbite structure with optimal comprehensive mechanical properties, achieving a perfect balance of high strength, high toughness, and good plasticity.

The quenching temperature of AISI 4340 steel is 840-870°C (full austenitization), and the preferred quenching medium is oil or polymer.After quenching, 4340 steel obtains a hard and brittle martensitic structure with a hardness of over 55 HRC and extremely high internal stress.

Principle: Tempering must be performed immediately after quenching!

Tempering temperature is the “master switch” for final performance. Practical experience shows that the optimal tempering temperature for AISI 4340 is 500~650℃, also known as high-temperature tempering. The tempering temperature can be adjusted as needed: lower temperatures result in higher hardness/strength, while higher temperatures provide better toughness.

AISI 4340+QT Steel Mechanical Property

| Tensile Strength | Yield Strength | Elongation | Reduction of Area | Impact Charpy-V | Hardness |

| 930-1100 Mpa | ≥740Mpa | ≥15% | ≥50% | ≥60J | 280-320HBW |

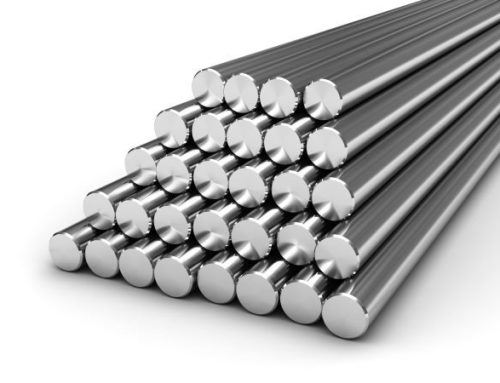

AISI 4340 STEEL SUPPLY FORM & SIZE & TOLERANCE

Are you in need of high-quality 4340 steel for your projects? Look no further than FUHONG—we are committed to meeting and exceeding all your expectations. As one of China’s premier special steel suppliers, we focus on delivering reliable, industry-specific 4340 steel products tailored to diverse application needs. We guarantee uncompromising, consistent quality in our 4340 steel for every project you undertake.

Get in touch with us today to dive deeper into our product solutions and see how FUHONG can elevate your product quality and project success. For all your special steel project needs, trust FUHONG as your reliable partner.

AISI 4340 steel Supplier,Stockist and Exporter,supplied with Round,Square,Flat,Block,and Shaft etc.

Hot Forged Round bar:Φ80-Φ1000mm

Hot Rolled Round bar:Φ14-Φ280mm

Hot Forged Square bar: Max Thickness:500mm

Flat bar/Blcoks:Thickness :120-800mm ,Width:120-1500mm

| Surface Finish | Black-Forged | Black-Rolled | Rough Turned | Cold Drawn | Peeled | Polished | Grinded |

| Tolerance | 0/+5mm | 0/+1mm | 0/+3mm | Best H11 | Best H9 | Best H9 | Best h8 |

Heat treatment:Quenched and Tempered (+QT), Normalizing (+N), Annealing (+A)

Surface finish:Black / Rough turned / Peeled