AISI 4140 steel is defined as a chromium-molybdenum low-alloy steel in the AISI/ASTM standard system.

The core characteristics of AISI 4140 steel are its good hardenability and heat treatment strengthening ability. Therefore, strength and toughness can be balanced through quenching and tempering to obtain excellent comprehensive mechanical properties.

As one of the most widely used chromium-molybdenum alloy steels in the industrial field, AISI 4140 steel is usually delivered in a pre-hardened condition with a hardness of 280-320 HBW.

AISI 4140 STEEL & EQUIVALENT GRADE CHEMICAL COMPOSITION

| Grade | C | Si | Mn | P | S | Cr | Mo |

| 4140 | 0.38-0.43 | 0.15-0.35 | 0.75-1.00 | ≤0.035 | ≤0.04 | 0.8-1.1 | 0.15-0.25 |

| 42CrMo | 0.38-0.45 | 0.17-0.37 | 0.5-0.8 | ≤0.035 | ≤0.035 | 0.9-1.2 | 0.15-0.25 |

| 42CrMo4 | 0.38-0.45 | ≤0.4 | 0.6-0.9 | ≤0.025 | ≤0.035 | 0.9-1.2 | 0.15-0.30 |

| SCM440 | 0.38-0.43 | 0.15-0.35 | 0.6-0.85 | ≤0.035 | ≤0.04 | 0.9-1.2 | 0.15-0.30 |

| EN19 | 0.35-0.45 | 0.15-0.35 | 0.5-0.8 | ≤0.035 | ≤0.035 | 0.9-1.5 | 0.20-0.40 |

AISI 4140 STEEL PHYSICAL PROPERTY

- Density: 7.85 g/cm³

- Melting point: approx. 1425-1475°C

- Thermal conductivity: approx. 42 W/(m・K) (room temperature)

- Elastic modulus: approx. 200 GPa

- Poisson’s ratio: 0.27-0.30

AISI 4140 STEEL FORGING

The core of 4140 steel forging is “temperature control, deformation control, and cooling control”.

To reduce the temperature difference between the inside and outside of 4140 steel and avoid cracks caused by rapid heating, it can be preheated and held at 600℃ and 800℃ in stages.Initial forging temperature should be carried out between 1100℃-1120℃,and final forging temperature shall not be lower than 850°C.

During forging, deformation should be slow, and the microstructure should be improved by multi-directional upsetting and drawing to ensure that the forging ratio is above 4.

After forging, 4140 steel should be cooled as slowly as possible in a furnace or in sand.

AISI 4140 STEEL HEAT TREATMENT

The core advantage of AISI 4140 steel is its excellent heat treatability. Its properties can be adjusted through different processes to meet the needs of various industrial applications.

Typical Heat Treatment Process for AISI 4140 Steel

- AISI 4140 Steel Normalizing

Normalizing is used to refine the structure of forgings that might have cooled non-uniformly after forged,and considered as a conditioning treatment before final heat treatment.

Normalizing temperature for AISI 4140 steel should be carried out between 870℃-900℃. hold suitable time for the steel to be thoroughly heated to complete the ferrite to austenite transformation.Finally, air cooling.

After normalizing, AISI 4140 steel can obtain a uniform fine-grained pearlite + ferrite structure with a hardness of HB200~240, which is easy to machine.

- AISI 4140 Steel Annealing

The full annealing temperature for AISI 4140 steel should be between 800℃ and 850℃, with an appropriate holding time to ensure sufficient heating, followed by slow cooling in the furnace.

After annealing, AISI 4140 steel not only completely eliminates internal stress, but also obtains a spheroidal pearlite structure with a hardness below 229 HB, resulting in better machinability.

Another commonly used process is stress-relief annealing: heating temperature 550~600℃, holding for 2~4 hours, and finally furnace cooling.This treatment process can eliminate more than 80% of the internal stress while maintaining the microstructure and hardness essentially unchanged.

- AISI 4140 Steel Quenching & Tempering

This is the core heat treatment process for improving the performance of AISI 4140 steel.The key is “quenching + high-temperature tempering,” which ultimately forms a uniform sorbitic structure, achieving an optimal balance of “strength, toughness, and plasticity.”

The quenching temperature for AISI 4140 steel should be between 840℃ and 875℃, and the quenching medium can be water or oil. After quenching, a martensitic structure (quenching core) is obtained, with a hardness reaching 50 HRC.

Tempering is usually performed immediately after quenching to eliminate the stress generated during quenching, but its core purpose is to obtain the desired properties.

AISI 4140 steel can be tempered in the range of 200-650°C as required. Practical experience shows that 4140 steel achieves optimal overall mechanical properties at a tempering temperature of 550-650°C.

AISI 4140+QT Steel Mechanical Property

| Tensile Strength | Yield Strength | Elongation | Reduction of Area | Impact Charpy-V | Hardness |

| 850-1000 Mpa | ≥670Mpa | ≥13% | ≥45% | ≥54J | 28-34HRC |

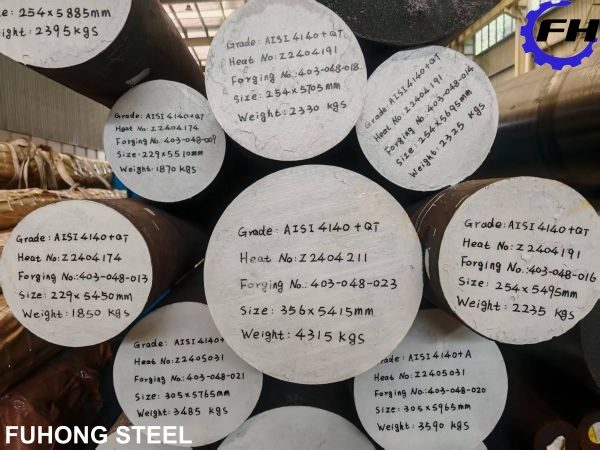

AISI 4140 STEEL SUPPLY FORM & SIZE & TOLERANCE

If you’re searching for reliable 4140 steel supplier who are based in China, FUHONG is the company you’ve been looking for. We have many years of experience and expertise in 4140 steel processing technology, thus we provide efficient and effective solutions when it comes to the 4140 steel. The professionals accompany every client personally to tailor the solution best for them. Get in touch with us and find out how FUHONG can improve your products.

AISI 4140 steel Supplier,Stockist and Exporter,supplied with Round,Square,Flat,Block,and Shaft etc.

Hot Forged Round bar:Φ80-Φ1000mm

Hot Rolled Round bar:Φ14-Φ290mm

Hot Forged Square bar: Max Thickness:500mm

Flat bar/Blcoks:Thickness :120-800mm ,Width:120-1500mm

| Surface Finish | Black-Forged | Black-Rolled | Rough Turned | Cold Drawn | Peeled | Polished | Grinded |

| Tolerance | 0/+5mm | 0/+1mm | 0/+3mm | Best H11 | Best H9 | Best H9 | Best h8 |

Heat treatment:Quenched and Tempered (+QT), Normalizing (+N), Annealing (+A)

Surface finish:Black / Rough turned / Peeled