EN36 steel is actually divided into EN36A, EN36B and EN36C, which belong to the Ni-Cr-Mo series of alloy steels as per BS970 standard.

As case hardening steel,EN36 series steel are characterized by high surface hardness,high strength,and soft core without loss of strength. EN36 series steel can also be quenched and tempered to obtain high strength and hardness.

In the field of mechanical engineering, EN36 steel is often used to manufacture mechanical parts with high wear resistance, such as gears, screws, shafts, rollers, etc. In addition, it is often used in aircraft engineering, shipbuilding, railway industry, oil industry and other fields.

EN36 STEEL CHEMICAL COMPOSITION

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo |

| EN36A | ≤0.15 | 0.1-0.35 | 0.3-0.6 | ≤0.05 | ≤0.05 | 0.6-1.1 | 3.0-3.75 | - |

| EN36B | 0.12-0.18 | 0.1-0.35 | 0.3-0.6 | ≤0.05 | ≤0.05 | 0.6-1.1 | 3.0-3.75 | - |

| EN36C | 0.12-0.18 | 0.1-0.35 | 0.3-0.6 | ≤0.05 | ≤0.05 | 0.6-1.1 | 3.0-3.75 | 0.10-0.25 |

EN36 STEEL RELATED STANDARD & EQUIVALENT GRADE

USA: 3310

Japan: SNC815

Europe:15NiCr13| DIN 1.5752

EN36 STEEL FORGING

- Initial Forging Temperature:1180-1200℃

- Final Forging Temperature:800-850℃

- Heating Rate:Strictly control the heating speed, which should be uniform and stable to prevent cracking caused by improper heating.

- Holding Time:Ensure that the material is fully and evenly heated,and the holding time should not be too long or too short.

- Forging Ratio:above 4:1

- Post-Forging Treatment:EN36 steel must be annealed after forging.

EN36 STEEL HEAT TREATMENT

Temperature Selection for Conventional Heat treatment for EN36 Steel

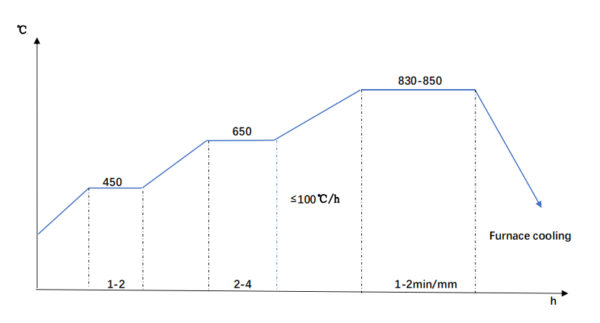

- Annealing:830 – 850°C,Cooling in furnace,hardness below 229 HBW

EN36 Steel Annealing Diagram

- Carburizing:880-980°C

- Core Hardening:840-880°C

- Case Hardening:780-820°C

- Tempering:150-200°C

EN36 Steel Mechanical Property As Per BS970

| Property | EN36A | EN36B | EN36C |

| Tensile Strength Mpa | ≥850 | ≥1004 | ≥1004 |

| Elongation, % | ≥15 | ≥13 | ≥13 |

| impact,J | ≥35 | ≥30 | ≥30 |

WHAT WE SUPPLY FOR EN36 SERIES STEEL

Hot Forged Round bar:Φ80-Φ1000mm

Hot Rolled Round bar:Φ16-Φ130mm

Hot Forged Square bar: Max Thickness:500mm

Flat bar/Blcoks:Thickness :120-800mm ,Width:120-1500mm

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |