DIN 1.2738 Tool Steel is pre-hardened plastic mold steel as per German standard.It contains Cr-Ni-Mo as its enhancing element,and has relatively superior mechanical properties in similar grades of steel,such as 1.2311,1.2312.

DIN 1.2738 steel has excellent processing properties,such as excellent polishing properties, good machinability and wear resistance.It is mainly used for the processing and production of hot work molds, among which the application of plastic molds is the most common.In addition, the special pre-hardening treatment of the steel is usually achieved by quenching and tempering heat treatment, and the hardness is usually 280-320HB.

DIN 1.2738 STEEL SUPPLY FORM & SIZE & TOLERANCE

Hot Forged Round bar:Φ80-Φ1000mm

Hot Rolled Round bar:Φ16-Φ130mm

Hot Forged Square bar: Max Thickness:500mm

Flat bar/Blcoks:Thickness :120-800mm ,Width:120-1500mm

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |

DIN 1.2738 STEEL CHEMICAL COMPOSITION

| Grade | C | Si | Mn | P | S | Cr | Mo | Ni |

| 1.2738 | 0.35-0.45 | 0.2-0.4 | 1.3-1.6 | ≤ 0.035 | ≤ 0.035 | 1.8-2.1 | 0.15-0.25 | 0.9-1.2 |

DIN 1.2738 STEEL RELATED STANDARD & EQUIVALENT GRADE

CHINA:3Cr2NiMo

USA:P20+Ni

ASSAB:718

JAPAN:PDS5S

DIN 1.2738 STEEL FORGING

- Initial Forging Temperature:1180℃

- Final Forging Temperature:850℃

- Forging Ratio:above 4:1

- Post-Forging Treatment:According to experience, 1.2738 steel is prone to white spot defects after forging, and it is a white spot sensitive steel.The recommended practice is to do annealing and dehydrogenation heat treatment immediately after forging.

DIN 1.2738 TOOL STEEL PHYSICAL PROPERTY

Density, g/cm3 | 20℃ | 200℃ | 400℃ |

| 7.8 | 7.75 | 7.7 | |

Thermal conductivity W/(m.K) | 20℃ | 200℃ | 400℃ |

| 29 | 29.5 | 31 | |

Linear expansion coefficient,10^-6/k | 20~200℃ | 20~400℃ | 20~500℃ |

| 12.6 | 13.5 | 14.3 | |

Modulus of elasticity,kN/mm2 | 20℃ | 200℃ | 400℃ |

| 205 | 200 | 185 |

DIN 1.2738 TOOL STEEL MAIN CHARACTERISTICS

- Uniform hardness

- Excellent polishing performance

- Excellent wear resistance

- Good machinability

- Suitable for nitriding

- Suitable for surface treatment, such as: Cr plating

DIN 1.2738 TOOL STEEL HEAT TREATMENT

- DIN 1.2738 steel Softening annealing

The annealing temperature is 710~740°C, and the holding time is determined by 1h per 25mm wall thickness. After holding, it will be cooled with the furnace.

- DIN 1.2738 steel Stress relief annealing

The heating temperature is 600°C (annealing condition), 550°C (quenching and tempering condition), the holding time is determined by 1h per 50mm wall thickness, and the furnance cooling after holding.

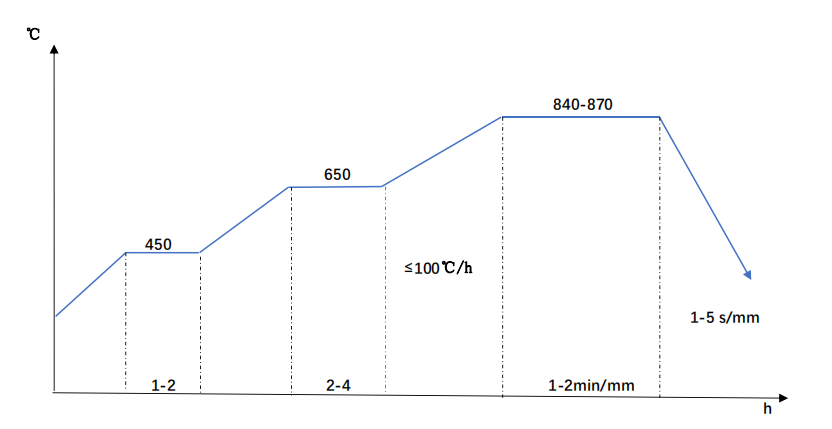

- DIN 1.2738 steel Quenching & Tempering

Pre-heat temperature:450°C with 1-2 hours,650°C with 2-4 hours.The suitable quenching temperature for DIN 1.2738 is 840-870°C.With Oil quench cooling to 50-70°C,then tempering immediately.The tempering holding time is determined by 1h per 25mm thickness of the workpiece, at least 2h.Hardness will be 280-340HBW.

DIN 1.2738 Steel Quenching Diagram

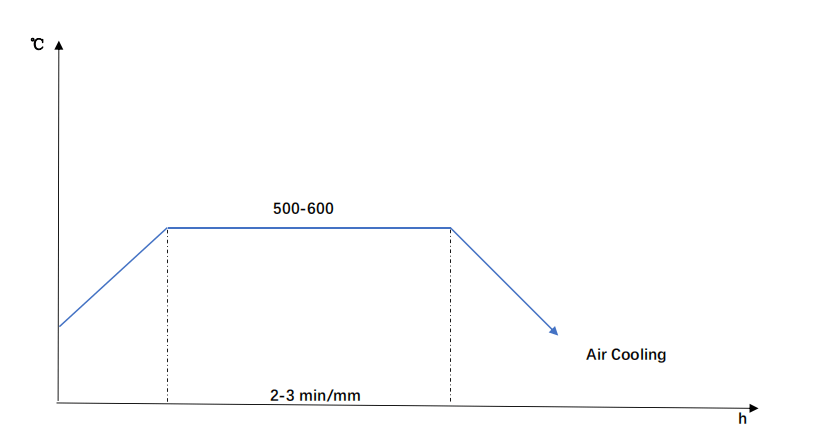

DIN 1.2738 Steel Tempering Diagram

DIN 1.2738 Steel Tempering Temperature Vs Hardness

| Tempering Temperature,ºC | 180ºC | 200ºC | 300ºC | 400ºC | 500ºC | 600ºC |

| Hardness,HRC | 52 | 51 | 48 | 46 | 42 | 34 |

DIN 1.2738 Steel Mechanical Property with Quenched and Tempered Condition

| Temperature | Tensile Strength Mpa | Yield Strength Mpa | Elongation % | Reduction of Area % | Impact Charpy-V J | Hardness,HBW |

| 20ºC | 1100 | 980 | 13 | 49 | 20 | 340 |

| 200ºC | 1050 | 925 | 14 | 51 | 32 | 340 |

| 400ºC | 850 | 770 | 16 | 52 | 42 | 340 |

- DIN 1.2738 Steel Induction hardening

DIN 1.2738 steel can be flame or induction hardened to increase the surface hardness to 50HRC, air-cooled after hardening. Small modules can use general quenching medium, and should be tempered immediately after hardening, and the tempering temperature should be 180~200°C.

- DIN 1.2738 Steel Nitriding Specifications

| Nitriding temperature,ºC | Nitriding time,h | Nitriding layer thickness,mm |

| 525 | 20 | 0.3 |

| 525 | 30 | 0.35 |

| 525 | 50 | 0.5 |

- DIN 1.2738 Steel Soft nitriding

Soft nitriding at 570°C for 2h, the surface hardness of the mold is about 700HV, and the depth of the nitrided layer is about 0.1mm

DIN 1.2738 TOOL STEEL APPLICATIONS

- Skin pattern, pear pattern, imitation stone pattern etching mould.

- Transparent plastics such as stationery boxes and daily necessities containers require high gloss molds.

- Especially suitable for hard glue (PS) and non-shredding glue (ABS) parts.

- Large molds with high production requirements such as automobile bumpers, interior parts, refrigerators, air conditioners, etc.

DIN 1.2738 Forged blocks with QT condition