DIN 1.2358 steel, also known as 60CrMoV18-5, is a medium-carbon chromium-molybdenum-vanadium alloy cold work tool steel under the German standard system.

Featuring “moderate load + impact resistance + dimensional stability,” DIN 1.2358 steel is gradually replacing traditional high-carbon, high-chromium steels (such as D2/DIN 1.2379), meeting wear resistance requirements while addressing the weakness of high-carbon, high-chromium steels in terms of insufficient toughness and susceptibility to cracking.

DIN1.2358 steel is widely used in cold-working molds, precision cutting tools and wear-resistant mechanical parts.

1.2358 STEEL CHEMICAL COMPOSITION

| Grade | C | Si | Mn | P | S | Cr | Mo | V |

| 1.2358/60CrMoV18-5 | 0.58-0.62 | 0.2-0.5 | 0.7-0.9 | ≤0.03 | ≤0.03 | 4.3-4.7 | 0.4-0.6 | 0.2-0.3 |

Core Element Characteristics

- Carbon: 0.58–0.62%(It forms carbides with Cr, Mo, and V, ensuring hardness and wear resistance after quenching; the medium carbon content avoids excessive reduction in toughness.)

- Chromium: 4.3–4.7%(Improve hardenability: Ensure uniform hardness of large cross-section parts; form Cr₂₃C₆ carbides, enhancing wear resistance and corrosion resistance (limited rust prevention).)

- Molybdenum: 0.4–0.6% (Optimize toughness and thermal stability: suppress temper brittleness and improve hardness retention at high temperatures; synergistically enhance hardenability with Cr.)

- Vanadium:0.2-0.3%(Refining grain size: Forming VC carbides (extremely high hardness), significantly improving wear resistance and red hardness; reducing heat treatment deformation.)

1.2358 Steel Physical Properties

- Density (ρ): 7.85 g/cm³

- Thermal Conductivity (λ): 28~32 W/(m·℃)

- Coefficient of Thermal Expansion (α): 11.9 μm/(m·℃)

- Resistivity (ρ): 0.22~0.26 μΩ·m

- Curie Temperature: ≈730℃

1.2358 Steel Processing Properties

- Forging Properties: Good. Forging temperature: 850~1050℃. Avoid forging below 800℃ (prone to cracking). Slow cooling and timely annealing after forging are recommended.

- Machining Properties: Good machinability in the annealed state (hardness ≤240 HB). Can be machined using high-speed steel or cemented carbide tools; no special tools required.

- Welding Properties: Moderate. Preheating to 200~300℃ is required before welding. Slow cooling and immediate tempering after welding (to relieve welding stress) are recommended to prevent cracking.

- Heat Treatment Properties: Excellent hardenability. Oil/air cooling is sufficient for section thickness ≤100mm, resulting in uniform hardness. Good tempering stability; low residual austenite content and dimensional stability after multiple temperings.

1.2358 STEEL HEAT TREATMENT

1.2358 Steel Softening Annealing

- Purpose: To reduce hardness, improve machinability, and eliminate forging/rolling stress;

- Process: Hold at 820~860℃ for 2~4 hours (adjust according to section thickness), furnace cool to 770℃, then control the cooling rate to ≤10℃/h, and finally air cool to 650℃;

- Result: Hardness ≤240 HB, easily machinable by turning, milling, drilling, etc.

1.2358 Steel Quenching

- Preheating: 600~750℃, hold for 1~2 hours (reduce thermal stress and avoid cracking);

- Austenitization: 950~970℃, hold for 2~3 hours (ensure full dissolution of alloying elements; excessively high temperatures can lead to coarse grains and decreased toughness);

- Cooling methods: Oil cooling (recommended, good hardenability and minimal deformation), air cooling (suitable for thin-section parts), hot bath quenching (salt bath/alkali bath, minimal deformation);

- Results: Hardness after quenching is 62~64 HRC, with residual austenite and internal stress, requiring immediate tempering.

1.2358 Steel Tempering

- Core requirements: Complete within 24 hours after quenching, with at least two tempering cycles (cooling to room temperature after each tempering) to ensure full transformation of residual austenite;

- Properties corresponding to different tempering temperatures (key selection criteria):

| Tempering Temperature | Tempering Times | Holding Time | Final Hardness | Applicable Scenarios |

| 180~200℃ | 2 times | ≥2h / time | 58~60 HRC | High wear resistance requirements (stamping dies, cutting tools) |

| 250℃ | 2 times | ≥2h / time | 55~57 HRC | Medium wear resistance + high toughness (bending dies, stretching dies) |

| 300℃ | 2 times | ≥2h / time | 52~54 HRC | High impact requirements (cold extrusion dies, thick plate stamping dies) |

| 350℃ | 2 times | ≥2h / time | 49~51 HRC | Wear resistance + fatigue resistance (mechanical parts, gears) |

Comparison With Similar Types of Steel

| Grade | Core Advantages | Core Disadvantages | Conclusion |

| Cr12MoV | Extremely high wear resistance | Poor toughness, prone to cracking | 1.2358 has better toughness, suitable for impact conditions; Cr12MoV is suitable for low-impact, high-wear-resistance applications. |

| D2/1.2379 | Better wear resistance and red hardness | Moderate toughness, slightly poor hardenability | D2 steel has stronger wear resistance, but 1.2358 has better impact resistance and machinability. |

| H13 | Good thermal stability (for hot-working dies) | Slightly inferior cold-working wear resistance | H13 is suitable for hot-working dies, 1.2358 is more suitable for cold-working applications. |

| 1.2358 | Balanced toughness, wear resistance, and machinability | Extreme wear resistance is not as good as D2/Cr12 | Best overall performance, suitable for most "balanced" cold-working applications. |

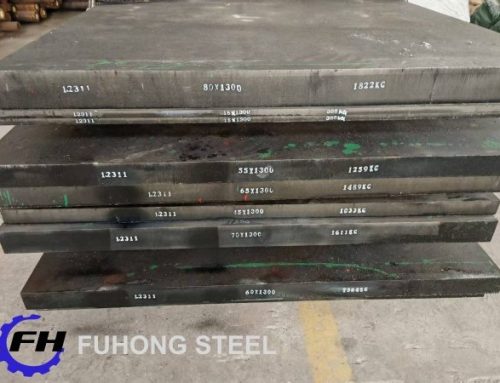

1.2358 STEEL SUPPLY FORM & SIZE & TOLERANCE

Hot Forged Round bar:Φ61-Φ505mm

Hot Rolled Round bar:Φ14-Φ56mm

Hot Forged Square bar: Max Thickness:400mm

Flat bar/Blcoks:Thickness :8-400mm ,Width:210-810mm

| Surface Finish | Black-Forged | Black-Rolled | Rough Turned | Cold Drawn | Peeled | Polished | Grinded |

| Tolerance | 0/+5mm | 0/+1mm | 0/+3mm | Best H11 | Best H9 | Best H9 | Best h8 |