8620 steel (US grade, corresponding to Chinese grade 20CrNiMo) is a low alloy carburizing steel. Due to its excellent comprehensive mechanical properties, it is widely used in fields with high requirements for surface hardness, wear resistance and core toughness. The following is a detailed description of its core applications and material properties:

8620 Steel Material Characteristics

- Chemical composition: 8620 steel contains alloying elements such as nickel, chromium, and molybdenum, providing good hardenability and toughness.

- Heat treatment performance: Suitable for carburizing treatment, the surface hardness and wear resistance are significantly improved while maintaining the toughness of the core.

- Application advantages

– High surface hardness: The surface hardness after carburizing can reach HRC 58-62, and the wear resistance is excellent.

– Good core toughness: The core hardness is low and can withstand impact and fatigue loads.

– Fatigue resistance: Suitable for gear applications with high cyclic stress and prolong service life.

– Processing performance: Easy to cut before heat treatment, suitable for the manufacture of complex gears.

8620 Steel Heat Treatment Process

1. Pretreatment: Normalizing or annealing

8620 raw materials need to be pretreated before carburizing, the purpose is to refine the grains, eliminate internal stress, and improve cutting performance.

- Normalizing process:

– Temperature: 870-900℃

– Holding time: 1-2 hours (adjusted according to the size of the workpiece)

– Cooling method: air cooling

– Purpose: homogenize the structure and provide a uniform matrix for subsequent carburizing. - Annealing process (optional):

– Temperature: 700-750℃

– Holding time: 2-4 hours, cooling with the furnace

– Applicable scenarios: used to eliminate residual stress after forging or cold working.

2. Carburizing (key step)

Carburizing forms a high carbon layer (carbon content 0.7-1.0%) on the surface to improve surface hardness and wear resistance, while the core maintains low carbon (0.15-0.25%) to ensure toughness.

- Carburizing method: gas carburizing (most commonly used) or vacuum carburizing.

- Process parameters:

– Temperature: 900-930℃ (typically 925℃)

– Time: 4-12 hours (adjusted according to the depth of the carburizing layer, usually 0.5-1.5mm)

– Carbon potential control: surface carbon concentration 0.8-1.0% (adjust the carbon potential in the furnace by propane or natural gas) - Cooling after carburizing:

– Direct quenching (less commonly used): direct quenching after carburizing, but deformation must be strictly controlled.

– Slow cooling (commonly used): furnace cooling or air cooling to room temperature after carburizing, and then reheating and quenching.

3. Quenching treatment

Transform austenite into martensite by rapid cooling (quenching) to obtain high hardness.

- Quenching method:

1. Reheating quenching (recommended):

– Temperature: 800-830℃ (slightly higher than the Ac3 temperature of the core material)

– Holding time: 1 hour/25mm (to ensure that the core is completely austenitized)

– Cooling medium: oil quenching (commonly used to reduce deformation) or water quenching (higher hardness, but greater risk of deformation).

2. Direct quenching (precision control only):

– Cool directly to the quenching temperature (about 830℃) after carburizing and then oil quench, but avoid grain coarsening. - Quenching target:

– Surface: high carbon martensite, hardness ≥60 HRC.

– Core: low carbon martensite or bainite, hardness 30-45 HRC, maintain toughness.

4. Tempering treatment

Eliminate quenching stress, adjust the balance between hardness and toughness, and prevent brittle fracture.

- Low temperature tempering:

– Temperature: 150-200℃

– Time: 1-2 hours

– Cooling method: air cooling

– Effect: retain high hardness (58-62 HRC on the surface), eliminate about 20% of quenching stress. - Medium temperature tempering (special needs):

– Temperature: 300-400℃

– Applicable scenarios: working conditions requiring slightly lower hardness and higher toughness (such as high impact loads).

5. Additional processes (optional)

- Cryogenic treatment:

– Temperature: -80℃ to -196℃

– Time: 1-4 hours

– Purpose: Reduce residual austenite and further improve surface hardness and dimensional stability (for precision gears). - Shot peening:

– Process: High-speed projectile impacts the surface

– Purpose: Introduce compressive stress and improve fatigue life.

8620 Steel Five Core Applications

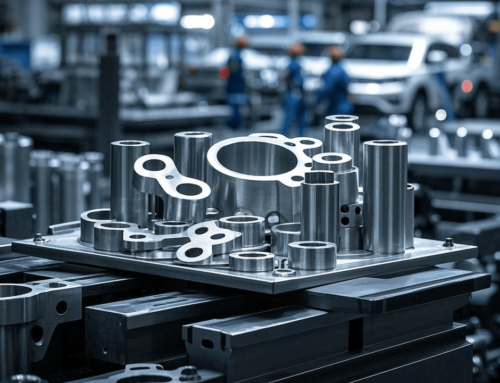

1. Automotive industry: key components of powertrain

- Core applications

– Transmission gears: main drive gears, synchronizer gears, etc.

– Differential gears: planetary gears, axle gears, etc.

– Engine parts: camshaft, crankshaft gears, etc. - Features and advantages

– High surface hardness: Carburizing treatment (surface hardness up to HRC 58-62) significantly improves the wear resistance and pitting resistance of gears, and adapts to high contact stress of frequent meshing.

– High toughness of the core: The low-carbon core (hardness HRC 30-45) can absorb impact loads and avoid gear fracture under rapid acceleration or high torque.

– Fatigue resistance: The gradient structure of the carburized layer and the core delays crack propagation and extends the life of the gear under cyclic loads.

– Lightweight design: While ensuring strength, the gear size can be reduced to help lightweight the car.

2. Industrial machinery: transmission core of heavy equipment

- Core applications

– Mining machinery: crusher gears, tunneling machine transmission gears.

– Engineering machinery: excavator slewing gears, crane reduction gears.

– Wind power equipment: yaw gears, pitch gears (need to be combined with surface coating to enhance weather resistance). - Features and advantages

– Impact resistance: The low-carbon martensite/bainite structure in the core can withstand severe impact when the equipment is started or stopped or overloaded.

– Wear resistance: The carburized layer can still maintain a low wear rate in harsh environments such as sand, stone, and dust.

– High load-bearing capacity: Alloy elements (Ni, Cr, Mo) improve hardenability and ensure uniform performance of the core of large-section gears.

– Processing adaptability: Good cutting performance before heat treatment, suitable for precision processing of complex gears.

3. Aerospace: High-reliability transmission system

- Core application

– Aircraft engine gears: accessory transmission gears, turbine shaft gears.

– Helicopter transmission system: main rotor reducer gears.

– Aerospace actuators: servo gears, solar panel drive gears. - Features and advantages

– High strength-to-weight ratio: Reduce component weight while ensuring strength, meeting aircraft weight reduction requirements.

– High temperature resistance: By optimizing the carburizing process (such as low-pressure vacuum carburizing), stability can be maintained below 300°C.

– Anti-fretting wear: High surface hardness reduces fretting wear of gears under high-frequency vibration.

– Dimensional stability: Combined with cryogenic treatment (below -80°C), residual austenite is reduced to avoid dimensional changes during long-term use.

4. Petroleum and energy equipment: a reliable choice under harsh working conditions

- Core applications

– Oil drilling equipment: mud pump gears, top drive transmission gears.

– Nuclear power equipment: coolant pump gears (must meet radiation resistance requirements).

– Hydropower generator sets: governor gears, coupling gears. - Features and advantages

– Corrosion resistance: can be treated by surface plating (such as nickel plating) or passivation after carburizing to adapt to humid, hydrogen sulfide-containing environments.

– Fatigue and creep resistance: stable performance under long-term alternating loads or high temperature and high pressure.

– Repairability: local wear can be repaired by laser cladding and other processes to reduce maintenance costs.

5. Other special fields

– Railway locomotives: traction motor gears, axle gears (resistant to vibration and shock).

– Ship propulsion system: propeller reduction gears (resistant to seawater corrosion requires a coating).

Summary: Cross-domain Advantages of 8620 Steel

8620 steel has become an ideal material for automobiles, industrial machinery, aerospace, energy equipment and other fields due to its “hard surface and tough inner” characteristics after carburizing, as well as excellent hardenability, fatigue resistance and processing performance. Its core advantages can be summarized as follows:

- Performance balance: a perfect combination of high surface hardness and high core toughness.

- Wide adaptability: by adjusting the depth of the carburized layer and the heat treatment process, it can meet different load and environmental requirements.

- Economical and efficient: lower alloy cost (compared to high alloy steel) and long life cycle, outstanding cost performance.

In the future, with the development of surface modification technology (such as plasma carburizing and nano coating), the application potential of 8620 steel under extreme working conditions will be further released.