Hot Work Tool Steel: The “Behind-The-Scenes Hero” Shaping The High-temperature World

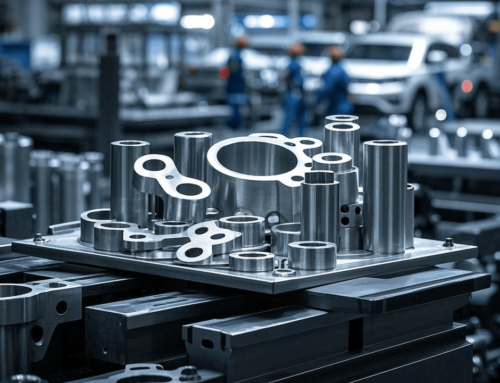

When you hold delicate metal parts in your hands or marvel at the precision structure of a car engine, have you ever wondered how these products are transformed from hot liquid metal into durable parts? Behind this, there is a class of obscure but crucial materials at work – hot work tool steel.Let’s continue to understand it in the form of questions and answers.

Q1: What is hot work tool steel? What is the difference between it and ordinary steel?

A:

Hot work tool steel is a special steel specially used to make molds working in high temperature environments. Compared with ordinary steel, it has the following core characteristics:

- High temperature resistance: It can maintain strength and hardness at high temperatures of 500℃~1000℃ to avoid softening and deformation.

- Resistant to thermal fatigue: It is not easy to crack when repeatedly heated and cooled.

- High thermal conductivity: It can quickly transfer heat to prevent local overheating of the mold.

- Corrosion and oxidation resistance: It can resist high temperature oxidation and erosion by molten metal.

Ordinary steel (such as carbon steel) is easy to soften and oxidize at high temperatures and cannot meet the needs of hot work molds.

Q2: What fields are hot work tool steel mainly used in?

A:

Hot work tool steel is the “behind-the-scenes hero” in many industrial fields. Typical applications include:

- Die casting die: manufacturing automotive parts (such as engine cylinder block), 3C electronic product housing, etc.

- Forging die: producing titanium alloy forgings for aerospace, high-speed rail hubs, etc.

- Extrusion die: processing aluminum alloy profiles (such as door and window frames).

- Hot stamping die: used for forming ultra-high strength steel body parts.

For example, Tesla’s integrated die-cast body relies on high-performance hot work tool steel.

Q3: Why can hot working tool steel withstand high temperatures? What is the scientific principle behind it?

A:

Its high temperature resistance comes from the special alloy design and microstructure:

- Alloy elements:

– Tungsten (W), molybdenum (Mo): form high melting point carbides to improve high temperature strength.

– Chromium (Cr), vanadium (V): enhance oxidation resistance and wear resistance.

– Cobalt (Co): improve red hardness (ability to maintain hardness at high temperatures). - Heat treatment process: tempered martensite structure is obtained through quenching + tempering, which has both toughness and strength.

- Second phase strengthening: carbide particles hinder dislocation movement at high temperatures to prevent material softening.

Q4: How to choose the right hot work tool steel?

A:

The following factors should be considered comprehensively when selecting materials:

| Factor | Description | Examples of common steel types |

| Working temperature | Select H11 below 600℃, HD (containing cobalt) above 800℃ | H13, HD, H21 |

| Impact load | High-impact conditions require high-toughness steel (such as H10) | H10, H21 |

| Cost | H13 has a lower cost-performance ratio than domestic steel | Domestic alternative materials (such as 4Cr5MoSiV1) |

Case: A certain automobile die-casting plant uses H13 steel to manufacture aluminum alloy cylinder head molds, with a service life of more than 100,000 times.

Q5: Why does hot work tool steel fail? How to extend its life?

A:

Common failure forms:

- Thermal fatigue cracks (accounting for more than 60%): cracks caused by repeated heating and cooling.

- Melting loss: corrosion of the mold surface by aluminum and magnesium alloy melts.

- Plastic deformation: local overheating causes material softening.

Key measures to extend service life:

- Surface treatment: nitriding (hardness increased to 1200HV), TD treatment (forming vanadium carbide coating).

- Precise temperature control: preheat the mold to 200~300℃ to avoid thermal shock.

- Digital monitoring: implant temperature sensors to warn of abnormal hot spots in real time.

Q6: What is the development trend of hot work tool steel in the future?

A:

The industry is moving towards “higher, lighter, and smarter” breakthroughs:

- Ultra-high thermal conductivity steel: such as copper (Cu) steel, thermal conductivity increased by 30%, shortening the production cycle.

- Additive manufacturing: 3D printing conformal cooling molds to solve the heat dissipation problem of complex structures.

- Smart materials: embedded self-healing microcapsules, automatically repairing tiny cracks.

Data reference: In 2023, the global hot work tool steel market size has reached US$4.5 billion, with an annual growth rate of 6.2%.

From smartphones to SpaceX rockets, hot work tool steel silently supports the extreme challenges of modern manufacturing. With the advancement of new material technology and intelligent manufacturing, the performance requirements for hot work tool steel are getting higher and higher. In the future, hot work tool steel will develop in the direction of higher strength, higher toughness and longer life. At the same time, the research and development of new hot work tool steel will also pay more attention to environmental protection and sustainability, such as developing low-alloy, low-energy hot work tool steel to reduce resource consumption and environmental pollution.

In short, as an indispensable key material for modern industry, hot work tool steel plays a vital role in promoting scientific and technological progress and industrial development. Although they are hidden behind the products and are not well known to people, it is the silent dedication of these “behind-the-scenes heroes” that allows us to enjoy the convenience and good life brought by modern technology.