SAE 4340 steel is a low alloy high strength steel grade under the standards of the American Society of Automotive Engineers(SAE).

SAE 4340 steel is usually delivered in two conditons, namely the pre-hardened conditon(quenched and tempered) and the annealed condition.

In the pre-hardened state, SAE 4340 has good strength, toughness, fatigue resistance and impact toughness.The pre-hardened hardness of SAE 4340 steel is usually controlled between 28-34HRC.While in the annealed state, the surface hardness of SAE 4340 is usually lower than 229HB, which is easy to machine.

SAE 4340 STEEL CHEMICAL COMPOSITION

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo |

| 4340 | 0.38-0.43 | 0.15-0.35 | 0.6-0.8 | ≤0.035 | ≤0.04 | 0.7-0.9 | 1.65-2.00 | 0.2-0.3 |

What is the difference between SAE 4340,AISI 4340 and ASTM 4340?

First of all, we can see that SAE 4340, AISI 4340, and ASTM 4340 are only different in the front letters. They represent an American association, namely the Society of Automotive Engineers (SAE), the American Iron and Steel Institute (AISI ), and the American Society for Testing and Materials (ASTM).While the number 4340 represents the American alloy steel grade 4340.

Therefore, there is no obvious difference between SAE 4340, AISI 4340, and ASTM 4340. Some of them are just different statements under different associations, but they all represent the grade 4340.

SAE 4340 STEEL RELATED STANDARD & EQUIVALENT GRADE

CHINA | GB 3077:40CrNiMoA

Europe | EN10083:34CrNiMo6/1.6582

JAPAN | JIS G4051:SNCM439

UK | BS970:EN24/817M40

SAE 4340 STEEL FORGING

- Initial Forging Temperature:1180-1230℃

- Final Forging Temperature: >850℃

- Heating Rate:Strictly control the heating speed, which should be uniform and stable to prevent cracking caused by improper heating.

- Forging Ratio:above 4:1

- Post-Forging Treatment:SAE 4340 is a Cr-Ni-Mo alloy steel with high sensitivity to white spots.According to our experience, for small-sized products, we recommend that they can be buried in sand for cooling, and for large-section products, we recommend annealing heat treatment immediately after forging.

SAE 4340 STEEL HEAT TREATMENT

SAE 4340 Steel Normalizing

- Normalizing temperature:850-900℃

- Holding time:Depending on the workpiece size and loading capacity, if the time is too long, the grains will be coarse, which will eventually affect the material properties.

- Cooling method: air cooling.Rapid cooling effect can also be achieved by spraying water mist.It should be noted that too fast cooling is not advisable, because it is easy to cause cracking of the material.

According to our experience, SAE 4340 steel needs normalizing heat treatment. Generally, it is to prepare for the final heat treatment to optimize the structure, so as to ensure the final performance of the material.

Another situation is that the SAE 4340 raw material has a large cross-sectional size, and normalizing heat treatment is required to refine the grains, so that the direction can be confirmed for the next process.

SAE 4340 Steel Annealing

SAE 4340 steel can be delivered in the annealed state. It is widely used in actual production, and its methods can also be said to be various. The commonly used annealing methods are generally divided into the following types.

- Complete annealing (recrystallization annealing):830-850°C,hardness below 200HB.

- Isothermal annealing:650°C,keep temperature for 8 hours,hardness below 229HB.

- Soft annealing: 670-700°C,hardness below 248HB.

- Stress relief annealing:600-650°C

The above annealing methods have their own effects, and their final cooling method is furnace cooling.

SAE 4340 Steel Quenching & Tempering(QT)

Quenching and tempering heat treatment is perfect for SAE 4340 steel itself to undergo a leapfrog performance change.After QT,SAE 4340 steel can obtain high strength and high hardness without losing its toughness,which has extremely high application value.

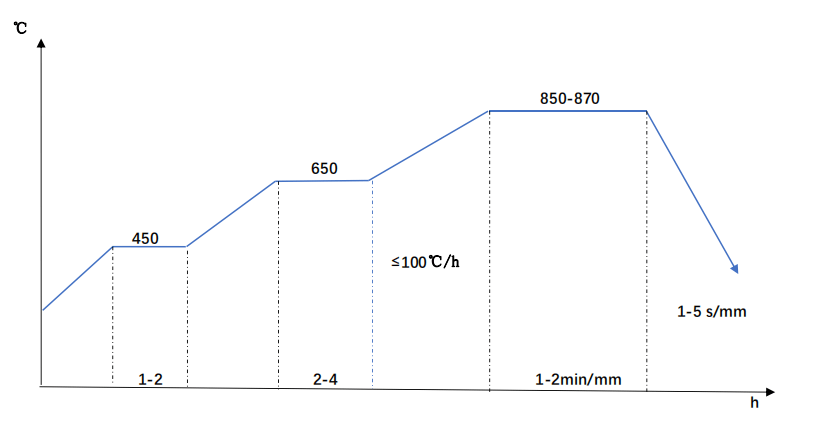

Quench Temperature:850-870°C

Quench Medium: Water/Oil

Quenching Hardness:55-59HRC

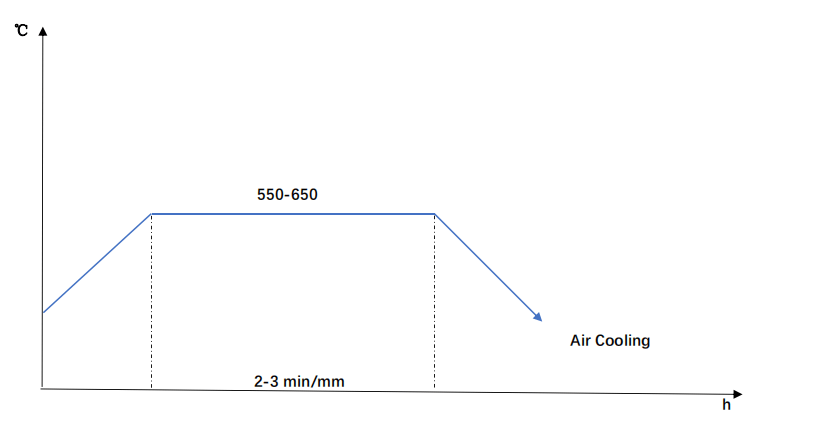

Tempering temperature:550-650°C

Tempering Hardness: 28-32HRC

SAE 4340 Steel Quenching Diagram

SAE 4340 Steel Tempering Diagram

SAE 4340 Steel Tempering Temperature Vs Hardness

| Grade | Quenching | Tempering Temperature,ºC | ||||||||

| Temperature,ºC | Hardness,HRC | 150ºC | 200ºC | 300ºC | 400ºC | 500ºC | 550ºC | 600ºC | 650ºC | |

| 4340 | 850ºC | >55 | 55 | 54 | 49 | 44 | 38 | 34 | 30 | 27 |

SAE 4340 Steel Mechanical Property with Quenched and Tempered Condition

| Quenching temperature | Tempering temperature | Tensile Strength Mpa | Yield Strength Mpa | Elongation % | Reduction of Area % | Impact Charpy-V J |

| 850°C/Oil | 400°C | ≥1900 | ≥1700 | ≥5 | ≥20 | ≥30 |

| 850°C/Oil | 600°C | ≥1000 | ≥850 | ≥12 | ≥55 | ≥100 |

SAE 4340 STEEL SUPPLY FORM & SIZE & TOLERANCE

Hot Forged Round bar:Φ80-Φ1000mm

Hot Rolled Round bar:Φ16-Φ200mm

Hot Forged Square bar: Max Thickness:500mm

Flat bar/Blcoks:Thickness :120-800mm ,Width:120-1500mm

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |

Heat treatment:Quenched and Tempered (+QT), Normalizing (+N), Annealing (+A)

Surface finish:Black / Rough turned / Peeled