SAE 1045 steel is an unalloyed medium carbon grade under the standards of the American Society of Automotive Engineers(SAE).

SAE 1045 steel is generally delivered in an unheated or normalized conditon.When delivered in the normalized state, SAE 1045 steel has good cold and hot workability and average strength, so it is widely used in machinery manufacturing.

SAE 1045 steel can obtain good mechanical properties through quenching and tempering heat treatment.After QT, the material properties have been greatly improved and can be used to manufacture various important structural parts.

SAE 1045 STEEL CHEMICAL COMPOSITION

| Grade | C | Si | Mn | P | S |

| 1045 | 0.43-0.50 | 0.15-0.35 | 0.60-0.90 | ≤0.04 | ≤0.05 |

What is the difference between SAE 1045,AISI 1045 and ASTM 1045?

In the actual commercial inquiry, we inevitably encounter 1045, SAE 1045, AISI 1045, ASTM 1045, there must be doubts, are they the same thing? Here we can tell you definitively, yes.

So, why is it called SAE, AISI, ASTM in front?

Actually, those who are familiar with American material grades know that SAE, AISI and ASTM represent the three major American associations, namely the Society of Automotive Engineers (SAE), the American Iron and Steel Institute (AISI), and the American Society for Testing and Materials (ASTM).

SAE 1045, AISI 1045, and ASTM 1045 are just different expressions, but they all represent the grade 1045. When engineers encounter such situations, they don’t deliberately distinguish them.

SAE 1045 STEEL RELATED STANDARD & EQUIVALENT GRADE

CHINA | GB 699:45#

Europe | EN10083:C45/1.0503

JAPAN | JIS G4051:S45C

UK | BS970:EN8/080M40

SAE 1045 STEEL FORGING

- Initial Forging Temperature:1180-1210℃

- Final Forging Temperature: >800℃

- Heating Rate:Strictly control the heating speed, which should be uniform and stable to prevent cracking caused by improper heating.According to our experience, segmental heating is a very good way. During the heating process, it can be kept at a certain temperature range such as 450°C and 650°C for a period of time, which can effectively solve the problem of uneven internal and external temperatures caused by excessive heating of materials.

- Forging Ratio:above 4:1

- Post-Forging Treatment:As a medium carbon steel, SAE 1045 steel is generally treated by slow cooling in sand after forging.However, sometimes for large-scale materials, slow cooling in the sand may make the grains of the material coarser. Therefore, air cooling is often used to obtain a certain grain size.

SAE 1045 STEEL HEAT TREATMENT

SAE 1045 Steel Normalizing

- Normalizing temperature:830-880℃

- Holding time:Depending on the workpiece size and loading capacity.According to our experience,if the size of SAE 1045 steel is small, the holding time is short. As the size becomes larger, the corresponding holding time will be extended.However, it is not that the longer the holding time, the better the normalizing effect. On the contrary, too long holding time will lead to coarse grains and overburning of the material, which will eventually affect the properties of the material.

- Cooling method: air cooling.Rapid cooling effect can also be achieved by spraying water mist.It should be noted that too fast cooling is not advisable, because it is easy to cause cracking of the material.

According to our experience,Normalizing is an important heat treatment process for SAE 1045 steel.First, for general purpose parts, normalizing can be used as the final heat treatment process for SAE 1045 steel to meet the specified properties.

Secondly, it can be used as a pre-preparation process for the final quenching and tempering heat treatment of SAE 1045 steel, the purpose is to refine the grain and homogenize the structure, and prepare the structure for the final heat treatment.

SAE 1045 Steel Mechanical Property in Normalized Condition

| Tensile Strength Mpa | Yield Strength Mpa | Elongation % | Reduction of Area % | Impact Charpy-V J | Hardness HBW |

| 670-720 | ≥340 | 15-18 | 45-50 | ≥50 | 170-240 |

SAE 1045 Steel Annealing

According to our experience, the purpose of annealing heat treatment for SAE 1045 steel is usually to soften the surface hardness for machining.

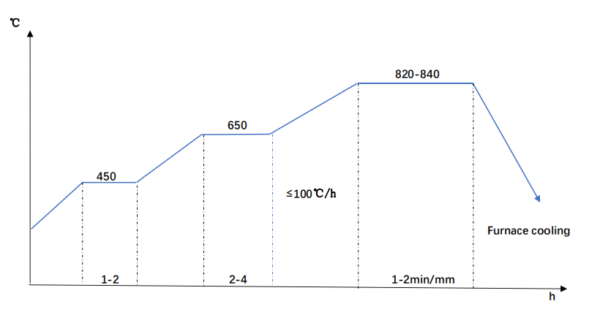

The annealing temperature of SAE 1045 steel is generally controlled at 820-840°C.After a sufficient holding time, the material can be cooled to room temperature in the furnace.The measured surface hardness of the material is usually lower than 200HBW, which is very easy for subsequent processing.

SAE 1045 Steel Annealing Diagram

SAE 1045 Steel Quenching & Tempering(QT)

When SAE 1045 steel is applied to important structural parts, such as connecting rods, gears, bolts and shafts working under alternating loads, the performance of SAE 1045 steel cannot meet the requirements after normalizing heat treatment.At this time, we need to consider quenching and tempering heat treatment of SAE 1045 steel, which can achieve good comprehensive mechanical properties.

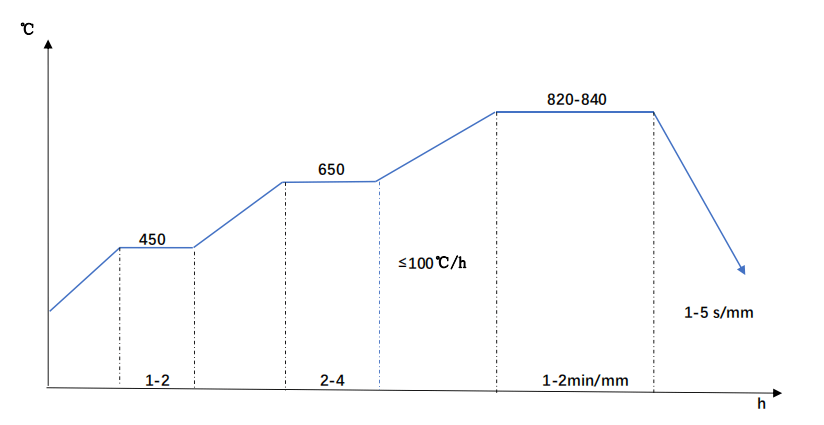

Quench Temperature:820-840°C

Quench Medium: Water/Oil

Quenching Hardness:55-60HRC

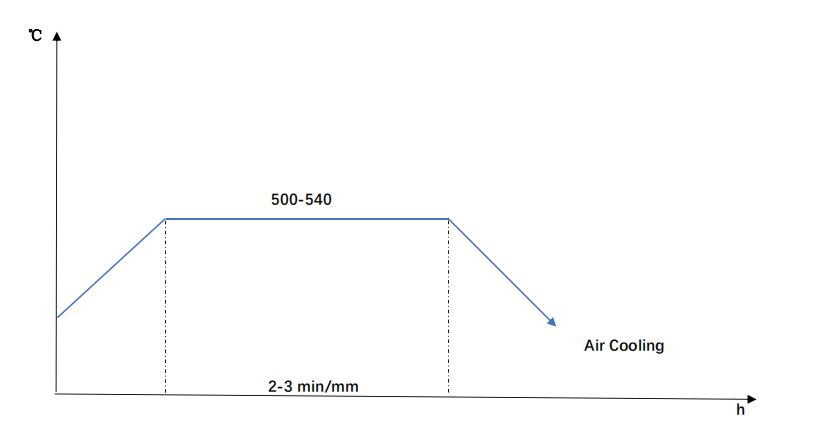

Tempering temperature:500-540°C

Tempering Hardness: 28-32HRC

SAE 1045 Steel Quenching Diagram

SAE 1045 Steel Tempering Diagram

SAE 1045 Steel Tempering Temperature Vs Hardness

| Grade | Quenching | Tempering Temperature,ºC | |||||||

| Temperature,ºC | Hardness,HRC | 150ºC | 200ºC | 300ºC | 400ºC | 500ºC | 550ºC | 600ºC | |

| SAE 1045 | 840ºC | 58-59 | 58 | 55 | 50 | 41 | 33 | 26 | 22 |

SAE 1045 Steel Mechanical Property with Quenched and Tempered Condition

| Quenching Temperature,ºC | Tempering Temperature,ºC | Tensile Strength Mpa | Yield Strength Mpa | Elongation % | Reduction of Area % | Impact Charpy-V J | Hardness |

| 820-840ºC, Water Quench | 180-200ºC | ≥1300 | ≥1150 | ≥6 | ≥22 | 15-25 | 50HRC Max |

| 820-840ºC, Water Quench | 560-620ºC | 700-850 | 450-560 | 15-17 | 45-50 | 60-80 | 196-241 HBW |

SAE 1045 STEEL SUPPLY FORM & SIZE & TOLERANCE

Hot Forged Round bar:Φ80-Φ1000mm

Hot Rolled Round bar:Φ16-Φ350mm

Hot Forged Square bar: Max Thickness:500mm

Flat bar/Blcoks:Thickness :120-800mm ,Width:120-1500mm

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |

Heat treatment:Quenched and Tempered (+QT), Normalizing (+N), Annealing (+A)

Surface finish:Black / Rough turned / Peeled