In domestic and foreign standards, 25CrMo4 belongs to alloy structural steel, and also belongs to quenched and tempered steel in special steel.It is distinguishing for its good matching of high strength and high toughness through certain heat treatment.

25CrMo4 Steel has excellent hardenability and tempering properties by adding proper Cr, Mo and other alloy elements.Through suitable tempering treatment,it maintains high strength and high toughness,as well as high temperature resistance,wear-resistant properties. 25CrMo4 Steel is suitable for the parts which serve in a complex environment.

25CrMo4 STEEL CHEMICAL COMPOSITION

| Standard | Grade | C | Si | Mn | P | S | Cr | Mo |

EN10083 | 25CrMo4/1.7218 | 0.22-0.29 | ≤0.4 | 0.6-0.9 | ≤0.025 | ≤0.035 | 0.9-1.2 | 0.15-0.3 |

| 25CrMoS4/1.7213 | 0.22-0.29 | ≤0.4 | 0.6-0.9 | ≤0.025 | 0.02-0.04 | 0.9-1.2 | 0.15-0.3 |

25CrMo4 STEEL RELATED STANDARD & EQUIVALENT GRADE

| China/GB 3077 | USA/ASTM A29 | UK/BS970 | Japan/JIS G4105 |

| 30CrMo | 4130 | 708M25 | SCM430 |

What is the Difference Between 25CrMo4,4130 and SCM430 Steel?

First of all, they all belong to Cr-Mo series low-alloy structural steel.As an equivalent grade, 4130 comes from ASTM A29 of American Standard, while SCM430 belongs to JIS G4105 of Japanese Standard.

| Grade | C | Si | Mn | P | S | Cr | Mo |

| 25CrMo4 | 0.22-0.29 | ≤0.4 | 0.6-0.9 | ≤0.025 | ≤0.035 | 0.9-1.2 | 0.15-0.3 |

| 4130 | 0.28-0.33 | 0.15-0.35 | 0.4-0.6 | ≤0.035 | ≤0.04 | 0.8-1.1 | 0.15-0.25 |

| SCM430 | 0.28-0.33 | 0.15-0.35 | 0.6-0.85 | ≤0.035 | ≤0.04 | 0.9-1.2 | 0.15-0.3 |

From the above table, we can clearly see that 25CrMo4 as a European steel grade is significantly higher than 4130 and SCM430 in the control requirements of harmful elements of sulfur and phosphorus.Due to the obvious difference in manganese elements, 4130 is difficult to replace 25CrMo4, while SCM430 and 24CrMo4 can be used instead of each other by adjusting the elements.

QUICK FAQS FOR 25CrMo4 STEEL

Can 25CrMo4 steel be used as quenched and tempered steel?

Yes,25CrMo4 steel is usually used in the quenched and tempered condition.After quenching and tempering, 25CrMo4 steel has high strength and toughness. In the machinery manufacturing industry, it is mainly used to manufacture parts with large cross-sections and work under high stress conditions.

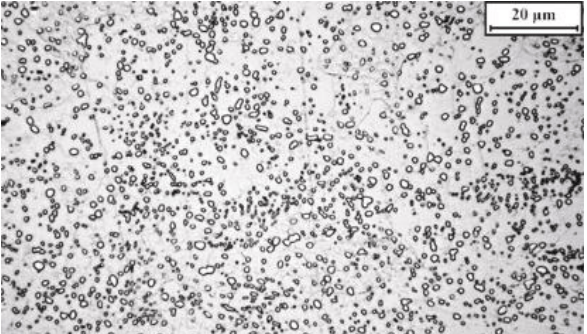

What is the Microstructure of 25CrMo4 Steel?

The hot-rolled microstructure of 25CrMo4 is ferrite and pearlite. The typical grain size is more than level 8. The typical Vickers hardness is from 200 to 250.

After spheroidizing annealing, 25CrMo4 can get 100% globular cementite microstructure, with Vickers hardness reduced to 125 or so, to obtain excellent formability.

25CrMo4 Steel Metallographic structure after spheroidizing annealing

How is the Processing Performance of 25CrMo4 Steel?

25CrMo4 has excellent heat-treatment properties. It can be used directly in hot-rolled condition, also can be cold-rolled for application of high precision parts. It is suitable for simple stamping parts in as rolled condition and suitable for fine-blanking and other complex forming after cold rolling and annealing to set good processibility.

Can 25CrMo4 Steel be welded?

When the alloying elements in 25CrMo4 steel are at the lower limit, the welding is quite good, but if it is close to the upper limit, the weldability is medium, and it needs to be preheated to above 175 ℃ before welding.

What is the Hardness of 25CrMo4 steel?

When we talk about the actual hardness of 25CrMo4 steel, it usually refers to the quenched and tempered state.The specific hardness reference is as follows

- 850±10℃ oil quenching,tempering at 680-700℃,Hardness:<217HBW

- 850±10℃ oil quenching,tempering at 560℃,Hardness:32-36HRC

- 850±10℃ oil quenching,tempering at 510℃,Hardness:36-42HRC

- 850±10℃ oil quenching,tempering at 480℃,Hardness:35-45HRC

- 850±10℃ oil quenching,tempering at 390℃,Hardness:48-52HRC

In addition, 25CrMo4 steel can also obtain high hardness by case hardening, such as nitriding.After nitriding, the surface hardness of 25CrMo4 steel can reach 550-700HV, and the nitration hardness depth is 0.2-0.7mm.

25CrMo4 STEEL FORGING

- Initial Forging Temperature:1180℃

- Final Forging Temperature:800℃

- Heating Rate:Strictly control the heating speed, which should be uniform and stable to prevent cracking caused by improper heating.

- Forging Ratio:above 4:1

- Post-Forging Treatment:Generally speaking,25CrMo4 steel should be slowly cooling in sand after forged.Also, annealing after forging is also recommended.

25CrMo4 STEEL HEAT TREATMENT

Temperature Selection for Different Types of Heat treatment for 25CrMo4 Steel

- Soft Annealing:650 – 700°C,Cooling in furnace,hardness below 212 HBW

- Normalizing:860-900°C

- Water Quenching:800-880°C, quenching hardenss above 47HRC.

- Oil Quenching:830-900°C,quenching hardenss above 47HRC.

- Tempering:540-680°C

25CrMo4 Steel Mechanical Property in Quenched and Tempered condition

| Diameter mm | ≤70 | 70-160 | 160-330 |

| Tensile Strength Mpa | ≥700 | ≥650 | ≥600 |

| Yield Strength Mpa | ≥450 | ≥400 | ≥380 |

| Elongation % | ≥15 | L:≥17 T:≥13 | L:≥18 T:≥14 |

| Impact Charpy J | ≥50 | L:≥45 T:≥27 | L:≥38 T:≥22 |

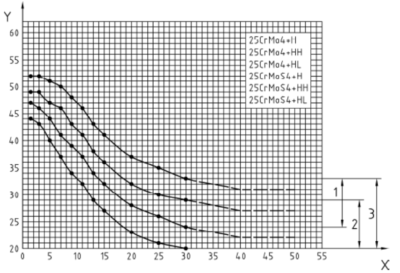

Jominy Quenching Test Curve For 25CrMo4 Steel

Quenching at 850°C

X:Distance from quenched end,in mm

Y:Hardness,HRC

1: HH level

2: HL level

3: H level

| Distance from quenched end mm | 1.5 | 3 | 5 | 7 | 9 | 11 | 13 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 |

| HRC Max | 52 | 52 | 51 | 50 | 48 | 46 | 43 | 41 | 37 | 35 | 33 | 32 | 31 | 31 | 31 |

| HRC Min | 44 | 43 | 40 | 37 | 34 | 32 | 29 | 27 | 23 | 21 | 20 | – | – | - | - |

25CrMo4 STEEL SUPPLY FORM & SIZE & TOLERANCE

Hot Forged Round bar:Φ80-Φ1000mm

Hot Rolled Round bar:Φ16-Φ130mm

Hot Forged Square bar: Max Thickness:500mm

Flat bar/Blcoks:Thickness :120-800mm ,Width:120-1500mm

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |

25CrMo4 STEEL APPLICATIONS

25CrMo4 Steel is mainly used in the mechanical engineering industry of automotive parts,oilfield equipment, etc.

Due to its excellent strength,toughness and wearresistance, 25CrMo4 is often used as cutting tools such as die cutter, saw matrix, etc. This steel maintains its hardness and strength even in the high temperatures,so it can be used in energy industries to make steam turbines, boiler fasteners. 25CrMo4 can also be used as a centralizer in the oil drilling work.