As a low alloy structural steel, 34CrMo4 steel contains Cr and Mo as alloy strengthening elements as per German standard DIN 17200.

34CrMo4 steel has high lasting strength and creep strength at high temperature, good impact toughness at low temperature, good hardenability and medium machinability.

34CrMo4 steel is usually used after quenched and tempered condition.It is often used as an important structural part working under high load, such as the transmission parts of vehicles and engines,the rotor,main shaft,and heavy-load transmission shaft of a turbo-generator, large gears for locomotive traction,supercharger transmission gears,rear shafts,connecting rods and spring clips that are heavily loaded, etc.

34CrMo4 STEEL CHEMICAL COMPOSITION

| Standard | C | Si | Mn | P | S | Cr | Mo |

| DIN 17200 | 0.3-0.37 | ≤ 0.4 | 0.6-0.9 | ≤0.035 | ≤0.03 | 0.9-1.2 | 0.15-0.3 |

| SEW 550 | 0.3-0.37 | ≤ 0.4 | 0.5-0.8 | ≤0.035 | ≤0.035 | 0.9-1.2 | 0.15-0.3 |

| EN10250 | 0.3-0.37 | ≤ 0.4 | 0.6-0.9 | ≤0.035 | ≤0.035 | 0.9-1.2 | 0.15-0.3 |

| EN10083 | 0.3-0.37 | ≤ 0.4 | 0.6-0.9 | ≤0.025 | ≤0.035 | 0.9-1.2 | 0.15-0.3 |

34CrMo4 STEEL RELATED STANDARD & EQUIVALENT GRADE

China | GB 3077: 35CrMo

USA | ASTM A29: 4135/4137

France:34CD4

UK | BS970:708M32

Italy:35CrMo4

34CrMo4 STEEL PHYSICAL PROPERTY

| Density, g/cm3 | 7.87 |

| Melting point,℃ | 1403 |

| Specific heat capacity,(0~100℃),J/(kg.k) | 561(100℃) |

| Linear expansion coefficient,10^-6/k | 12.5(0-100℃) |

| Poisson’s ratio | 0.286 |

| Elastic Modulus,Mpa | 217000 |

| Shear modulus,Mpa | 84000 |

| Thermal conductivity,W/(m.K) | 47.73(105℃) |

34CrMo4 STEEL FORGING

- Initial Forging Temperature:1150℃

- Final Forging Temperature:850℃

- Heating Rate:Strictly control the heating speed, which should be uniform and stable to prevent cracking caused by improper heating.

- Forging Ratio:above 4:1

- Post-Forging Treatment:34CrMo4 steel should be slowly cooling in sand after forged.Also, annealing after forging is also recommended.

34CrMo4 STEEL HEAT TREATMENT

Critical Temperature for Heat Treatment of 34CrMo4 Steel

- Ac1:755℃

- Ac3:800℃

- Ar1:695℃

- Ar3:750℃

- Ms:271℃

Temperature Selection for Conventional Heat treatment for 34CrMo4 Steel

- Annealing:820 – 840°C,Cooling in furnace

- Normalizing:830-860°C,air cooling

- Quenching:830-870°C,Medium:Water,Oil

- Tempering:540-680°C

34CrMo4 Steel Mechanical Property with Quenched and Tempered Condition

| Tensile Strength Mpa | Yield Strength Mpa | Elongation % | Reduction of Area % | Impact Charpy-V J |

| ≥1000 | ≥850 | ≥12 | ≥45 | ≥80 |

34CrMo4 Steel Tempering Temperature Vs Hardness

| Grade | Quenching | Tempering Temperature,ºC | ||||||||

| Temperature,ºC | Hardness,HRC | 150ºC | 200ºC | 300ºC | 400ºC | 500ºC | 550ºC | 600ºC | 650ºC | |

| 34CrMo4 | 850ºC | >55 | 55 | 53 | 51 | 43 | 34 | 32 | 28 | 24 |

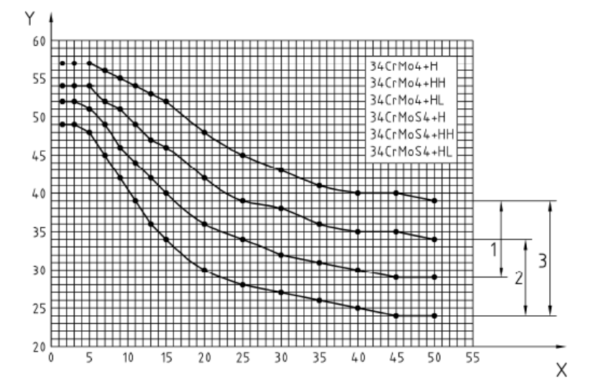

Jominy Quenching Test Curve For 34CrMo4 Steel

Quenching at 850°C

X:Distance from quenched end,in mm

Y:Hardness,HRC

1: HH level

2: HL level

3: H level

| HRC-mm | Type | 1.5 | 3 | 6 | 7 | 9 | 11 | 13 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 |

| MIN | +H | 49 | 49 | 48 | 45 | 42 | 39 | 36 | 34 | 30 | 28 | 27 | 26 | 25 | 24 | 24 |

| MAX | 57 | 57 | 57 | 56 | 55 | 54 | 53 | 52 | 48 | 45 | 43 | 41 | 40 | 40 | 39 | |

| MIN | +HH | 52 | 52 | 51 | 49 | 46 | 44 | 42 | 40 | 36 | 34 | 32 | 31 | 30 | 29 | 29 |

| MAX | 60 | 60 | 59 | 58 | 58 | 57 | 57 | 56 | 55 | 52 | 51 | 49 | 48 | 46 | 45 | |

| MIN | +HL | 49 | 49 | 48 | 45 | 42 | 39 | 36 | 34 | 30 | 28 | 27 | 26 | 25 | 24 | 24 |

| MAX | 54 | 54 | 54 | 52 | 51 | 49 | 47 | 46 | 42 | 39 | 38 | 36 | 35 | 35 | 34 |

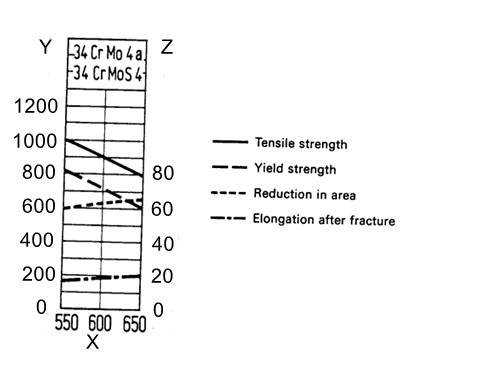

Guideline value Curve for 34CrMo4 Steel Mechanical Property

X:Tempering temperature,oC

Y:Tensile and Yield Strength,Mpa

Z:Elongation and Reduction in area,%

WHAT WE SUPPLY FOR 34CrMo4 STEEL

Hot Forged Round bar:Φ80-Φ1000mm

Hot Rolled Round bar:Φ16-Φ130mm

Hot Forged Square bar: Max Thickness:500mm

Flat bar/Blcoks:Thickness :120-800mm ,Width:120-1500mm

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |