DIN 1.2842/90MnCrV8 steel is defined as Mn-Cr-V tool steel as per DIN 17350 standard.

As a European standard cold work tool steel, DIN 1.2842 steel is also one of the most widely used tool steels. It has high hardness and wear resistance, good machinability and dimensional stability.

DIN 1.2842 steel is usually supplied in the annealed condition.It is mainly used for cutting and stamping tools, extrusion dies for thermoplastics, blow molding dies, forming tools and structural parts, etc.

DIN 1.2842/90MnCrV8 STEEL SUPPLY FORM & SIZE & TOLERANCE

Hot Forged Round bar:Φ80-Φ1000mm

Hot Rolled Round bar:Φ16-Φ130mm

Hot Forged Square bar: Max Thickness:500mm

Flat bar/Blcoks:Thickness :120-800mm ,Width:120-1500mm

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |

DIN 1.2842/90MnCrV8 STEEL CHEMICAL COMPOSITION

| Grade | C | Si | Mn | P | S | Cr | V |

| 1.2842 | 0.85-0.95 | 0.1-0.4 | 1.9-2.1 | ≤ 0.03 | ≤ 0.03 | 0.2-0.5 | 0.05-0.15 |

DIN 1.2842 STEEL RELATED STANDARD & EQUIVALENT GRADE

China:9Mn2V

USA:O2

DIN 1.2842 STEEL FORGING

- Initial Forging Temperature:980-1050℃

- Final Forging Temperature:800-850℃

- Forging Ratio:above 4:1

- Cooling Method After Forged:As high carbon tool steel,DIN 1.2842 steel should be annealed after forging.

DIN 1.2842 STEEL HEAT TREATMENT

Critical Temperature for Heat Treatment of DIN 1.2842 Steel

- Ac1:736℃

- Ac3:765℃

- Ar1:652℃

- Ms:180℃

DIN 1.2842 Steel Annealing

The general annealing temperature for 1.2842 steel is 750-770℃ with holding time 3-6h.With cooling ratw below 30℃/h, cooled to 550-600℃,then air-cooling.The hardness will be below 229HBW.

While for Isothermal annealing of 1.2842 steel,the heating temperature is controlled at 760-780℃, and the holding time is 2-3h. Then the isothermal temperature should be controlled at 680-700℃ with holding time 3-4h. Cooling at a cooling rate of ≤30℃/h to 500-600℃, finally air cooling.

DIN 1.2842 Steel Quenching & Tempering

Pre-heat Temperature:650℃

Quenching Temperature:780-820℃

Quenching Medium:oil

Tempering Temperature:150-200℃ Followed by Quenching

Hardness:60-62HRC

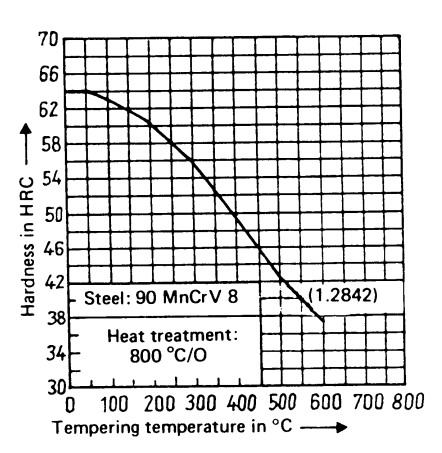

DIN 1.2842 Steel Tempering vs Hardness Diagram

DIN 1.2842 Steel Tempering vs Hardness Diagram

DIN 1.2842 STEEL TYPICAL APPLICATIONS

- Suitable for making various precision templates, block gauges and measuring tools with small deformation and good wear resistance

- Suitable for making small stamping dies with thickness less than 6mm.

- Suitable for scissors, taps, dies and reamers, etc.

- After quenching and low temperature tempering, its hardness is ≤55HRC, which is suitable for molds with small production batches and high requirements on strength and wear resistance.

- Higher-sized punching dies, cold pressing dies, engraving dies, and plastic dies.

- For making thermosetting plastic molds with quenching hardness of 46~52HRC

- Small cores, punches, cavity plates, inserts, etc.

- For solid hardened plastic molds.

- Suitable for making plastic molds with smaller size, more complex shape and higher precision.

- Thermosetting plastic molding die, requiring high wear resistance and high strength

DIN 1.2842 Forged Flat Steel