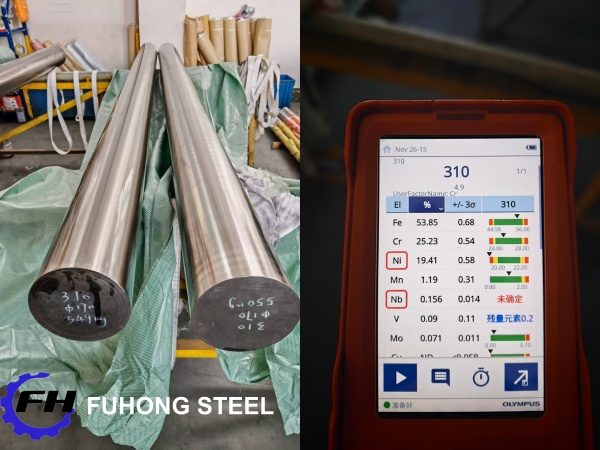

310 and 310S steels belong to the high-chromium, high-nickel austenitic stainless steel category in the ASTM standard. The only difference is that 310S has a carbon content of less than 0.08%, making it a low-carbon version of 310 steel (C≤0.25%).

310 stainless steel is typically delivered in the solution-treated condition, with a room temperature tensile strength usually between 550-650 MPa, which is basically the same as 310S. Due to its excellent resistance to high-temperature oxidation, creep resistance, and good corrosion resistance, ther are widely used in high-temperature working conditions and corrosive environments.

310/310S STEEL CHEMICAL COMPOSITION

| Grade | C | Si | Mn | P | S | Cr | Ni |

| 310 | ≤0.25 | ≤1.5 | ≤2.0 | ≤0.045 | ≤0.03 | 24.0-26.0 | 19.0-22.0 |

| 310S | ≤0.08 | ≤1.5 | ≤2.0 | ≤0.045 | ≤0.03 | 24.0-26.0 | 19.0-22.0 |

310 STEEL EQUIVALENT GRADE

China:06Cr25Ni20

Europe:X15CrNiSi25-20/1.4841

Japan:SUS310S

310 STEEL PHYSICAL PROPERTY

- Density: 7.98 g/cm³

- Melting Point: 1398~1454℃

- Thermal Conductivity (20℃): 15.2 W/(m·K)

- Coefficient of Linear Expansion (20~1000℃): 18.4×10^-6/℃

- Resistivity (20℃): 0.78 Ω·mm²/m

- Magnetic Properties: Non-magnetic / Weakly magnetic

310 STEEL HEAT TREATMENT

310 stainless steel has an austenitic structure and no magnetic phase transformation, so it cannot be hardened by quenching. Its heat treatment mainly involves solution treatment and stress-relieving annealing. The specific process is as follows:

310 Steel Solution Treatment

Heat 310 steel to 1030~1180℃, holding time determined by workpiece thickness (usually 1~2 hours for every 25mm thickness). Cooling method is water cooling or forced air cooling (air cooling is sufficient for thicknesses <6mm; thicker parts require water cooling for rapid cooling).

Core Objectives:

1. Dissolve carbides precipitated at grain boundaries (such as Cr₂₃C₆), restoring single-phase austenite structure;

2. Eliminate work hardening and internal stresses generated by cold working or welding;

3. Ensure the material’s corrosion resistance and high-temperature toughness.

310 Steel Mechanical Property in Solution Treatment Condition

| Tensile,Mpa | Yield,Mpa | Elongation,% | Reduction of Area,% | Hardness,HBW |

| ≥515 | ≥205 | ≥40 | ≥50 | ≤201 |

Notes: 310S, with a carbon content ≤0.08%, exhibits significantly better resistance to sensitization after solution treatment than ordinary 310, making it more suitable for components requiring long-term service at temperatures above 600℃.

310 Steel Stress-Relief Annealing

Heat 310 steel to 800~900℃, hold for 1~3 hours, then slowly cool (air cooling is acceptable if furnace cooling is below 500℃).

Applicable scenarios: Welded parts, cold-bent/stamped parts. It can eliminate residual stress and prevent stress corrosion cracking in subsequent high-temperature or corrosive environments.

Heat Treatment Precautions for 310 Steel

- Prolonged holding at 600~800℃ is prohibited, otherwise chromium carbides will precipitate along grain boundaries, causing intergranular corrosion;

- Tempering is not required, as tempering has no performance improvement effect on austenitic structures.

QUICK FAQS FOR 310 STEEL

Is 310 steel resistant to high temperatures?

310 steel has a continuous operating temperature of ≤1150℃, and an intermittent operating temperature of ≤1010℃. Within this range, a stable Cr₂O₃ protective film can form without significant oxidation peeling.

310 steel can withstand temperatures up to 1200℃ for short periods (several hours), making it suitable for rapid heating and cooling conditions in high-temperature furnaces.

What are the high-temperature mechanical properties of 310 steel?

The core advantage of 310 stainless steel lies in its high-temperature mechanical performance, which is the key difference between it and 304/316:

- High-Temperature Tensile Strength: At 900℃, the tensile strength is still ≥100MPa; at 1000℃, it is approximately 60MPa; and at 1100℃, it maintains above 30MPa, far exceeding conventional stainless steel.

- Creep Resistance: Under 800℃ and 100MPa stress, the creep rupture time can reach over 1000 hours, making it suitable for high-temperature load-bearing components.

- High-Temperature Fatigue: Under cyclic conditions of 600~800℃, its fatigue life is 3~5 times that of 304 stainless steel.

Is 310 steel resistant to chemical corrosion?

310 steel exhibits excellent corrosion resistance to dilute nitric acid and oxidizing acids (e.g., nitric acid concentration <65%).

310 steel has some resistance to dilute sulfuric acid (concentration <10%, temperature <60℃), but the corrosion rate increases significantly with increasing concentration or temperature.

Weaknesses: 310 steel is prone to pitting/crevice corrosion in hydrochloric acid and high-concentration chloride environments, making it unsuitable for coastal areas or chlorine-containing wastewater conditions.

Which is better, 310 or 310S stainless steel?

There is no absolute “better” between 310 and 310S; it depends on the application.310S is a low-carbon improved version of 310, which is superior in welding, resistance to intergranular corrosion, and long-term high-temperature stability; while 310 has slightly higher strength at room temperature and lower material cost.

How to choose between 310 and 304 stainless steel?

There’s no absolute good or bad between 304 and 310 stainless steel; the key difference lies in the application scenario. Their positioning and advantages differ significantly:

- 304 Stainless Steel: A general-purpose austenitic stainless steel (18% Cr + 8% Ni), offering high cost-effectiveness, good machinability, and meeting general requirements for atmospheric and weak acid/alkali corrosion resistance. Suitable for kitchenware, building decoration, food processing equipment, and other general applications at normal or medium-low temperatures (≤800℃).

- 310 Stainless Steel: A high-chromium-nickel heat-resistant austenitic stainless steel (24% Cr + 20% Ni), possessing extremely strong high-temperature resistance and oxidation resistance. It can be used long-term in environments of 1000-1200℃, and its corrosion resistance is superior to 304. However, it is more expensive and slightly more difficult to process, making it suitable for high-temperature kilns, heat treatment equipment, boiler combustion chambers, and other high-temperature conditions.

In short: Choose 304 for general applications, and 310 for harsh high-temperature environments.

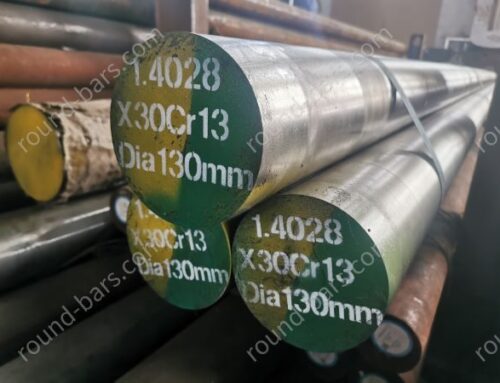

310/310S STEEL SUPPLY FORM & SIZE & TOLERANCE

Round bar: Dia 6-400mm

Square bar: Dia 6-200mm

Flat bar:2 x 10-20 x 200mm

Hexagonal bar: Dia 6-150mm

| Surface Finish | Black-Forged | Black-Rolled | Rough Turned | Cold Drawn | Peeled | Polished | Grinded |

| Tolerance | 0/+5mm | 0/+1mm | 0/+3mm | Best H11 | Best H9 | Best H9 | Best h8 |