5120 steel is a low carbon alloy structural steel containing 0.7-0.9% chromium as per American standard ASTM A29.

Due to its good toughness, forgeability and weldability, 5120 steel can meet the manufacturing needs of various shapes and sizes. This alloy steel responds well to heat treatment processes, and its hardness and strength can be adjusted through heat treatment.

After carburization, 5120 alloy steel has high hardness and wear resistance. It not only withstands high loads and impact loads, but also resists friction and wear, extending the service life of the material. Therefore, it is widely used in the manufacturing of automotive parts, such as transmissions,gears, crankshafts, piston pins, etc.

5120 STEEL CHEMICAL COMPOSITION

| Grade | C | Si | Mn | P | S | Cr |

| 5120 | 0.17-0.22 | 0.15-0.35 | 0.7-0.9 | ≤0.035 | ≤0.04 | 0.7-0.9 |

5120 STEEL RELATED STANDARD & EQUIVALENT GRADE

CHINA:20Cr

JAPAN:SCr420

EN/DIN:20Cr4/1.7027

5120 STEEL PHYSICAL PROPERTY

| Density, g/cm3 | 7.83 |

| Melting point,℃ | 1430 |

| Specific heat capacity,(0~100℃),J/(kg.k) | 477 |

| Linear expansion coefficient,10^-6/k | 13.56 |

| Poisson’s ratio | 0.3 |

| Elastic Modulus,Mpa | 210100 |

| Shear modulus,Mpa | 82400 |

| Thermal conductivity,W/(m.K) | 50.66(20℃) |

5120 STEEL FORGING

- Initial Forging Temperature:1200℃

- Final Forging Temperature:>800℃

- Forging Ratio:above 4:1

- Cooling Method After Forged:As low carbon alloy steel,5120 steel is generally treated by slow cooling in sands after forging.

5120 STEEL HEAT TREATMENT

Critical Temperature for Heat Treatment of 5120 Steel

- Ac1:766℃

- Ac3:838℃

- Ar1:702℃

- Ar3:799℃

Temperature Selection for Different Types of Heat treatment for 5120 steel

- Normalizing: 870 – 900°C,Cooling in air,hardness below 207HBW

- Annealing:860 – 890°C,Cooling in furnace,hardness below 179HBW

- Carburizing:900-940°C

- Core-hardening:850-870°C

- Case-hardening:780-820°C

- Tempering:180-200°C,Surface hardness:58-62HRC,Core hardness20-32HRC.

5120 Steel Mechanical Property with Quenched and Tempered Condition

| First Quenching Temperature,ºC | Second Quenching Temperature,ºC | Tempering Temperature,ºC | Tensile Strength Mpa | Yield Strength Mpa | Elongation % | Reduction of Area % | Impact Charpy-V J |

| 880ºC W/O Quench | 800ºC W/O Quench | 200ºC | ≥850 | ≥550 | ≥10 | ≥40 | ≥60 |

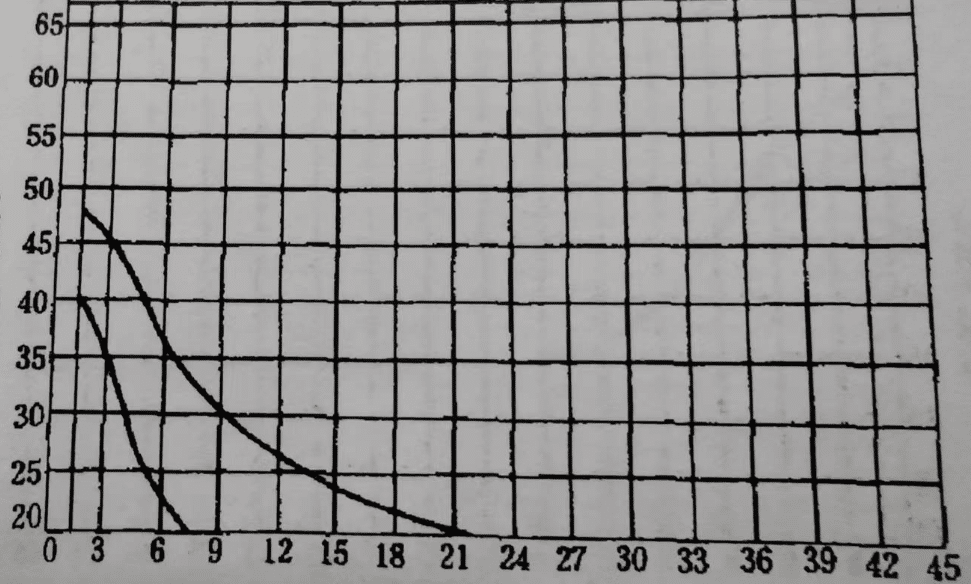

Jominy Quenching Test Curve For 5120 Steel

5120 STEEL SUPPLY FORM & SIZE & TOLERANCE

Hot Forged Round bar:Φ80-Φ1000mm

Hot Rolled Round bar:Φ16-Φ350mm

Hot Forged Square bar: Max Thickness:500mm

Flat bar/Blcoks:Thickness :120-800mm ,Width:120-1500mm

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |