As a low alloy structural steel, 39NiCrMo3 steel contains at least 0.6% Cr and 0.7% Ni elements as strengthening alloy elements as per EN10083 standard.

39NiCrMo3 steel has high strength & high toughness, good hardenability, thermal stability and excellent cold and hot deformation ability.However, it also has the shortcomings of high white point sensitivity, temper brittleness and poor weldability.

39NiCrMo3 steel is generally used in the quenched and tempered state to make important parts with high strength and good plasticity, such as shafts, gears, fasteners, engine casings, bearings, dies, spacers, etc.

39NiCrMo3 STEEL CHEMICAL COMPOSITION

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo |

| 39NiCrMo3/1.6510 | 0.35-0.43 | 0.1-0.4 | 0.5-0.8 | ≤0.025 | ≤0.035 | 0.6-1.0 | 0.7-1.0 | 0.15-0.25 |

39NiCrMo3 STEEL RELATED STANDARD & EQUIVALENT GRADE

China | GB 3077:40CrNiMoA

USA | ASTM A519: 9840

Germany/DIN 17200: 36CrNiMo4

39NiCrMo3 STEEL FORGING

- Initial Forging Temperature:1150℃

- Final Forging Temperature:850℃

- Heating Rate:Strictly control the heating speed, which should be uniform and stable to prevent cracking caused by improper heating.

- Holding Time:Ensure that the material is fully and evenly heated,and the holding time should not be too long or too short.

- Forging Ratio:above 4:1

- Post-Forging Treatment:39CrNiMo3 steel is a white point sensitive steel. For small-sized parts, the most common treatment after forging is to bury it in a sand pit and cool it slowly to fully allow the hydrogen to escape.For parts with relatively large size, if the hydrogen cannot fully escape during the cooling process, white spots will occur, and eventually the material will be scrapped. In this case, the recommended treatment is to do a dehydrogenation heat treatment immediately after forging.

39NiCrMo3 STEEL HEAT TREATMENT

Critical Temperature for Heat Treatment of 39NiCrMo3 Steel

- Ac1:740℃

- Ac3:790℃

- Ms:330℃

Temperature Selection for Conventional Heat treatment for 39NiCrMo3 Steel

- Soft Annealing:650 – 690°C,Cooling in furnace,hardness below 240 HBW

- Normalizing:860-880°C,air cooling

- Quenching:830-850°C,Medium:Water,Oil

- Tempering:540-630°C

39NiCrMo3 Steel Mechanical Property in Quenched & Tempered condition

| Diameter d mm | ≤ 16 | 16-40 | 40-100 | 100-160 | 160-250 |

| Yield Strength Mpa | ≥785 | ≥735 | ≥685 | ≥635 | ≥540 |

| Tensile Strength Mpa | 980-1180 | 930-1130 | 880-1080 | 830-980 | 740-880 |

| Elongation, % | ≥11 | ≥11 | ≥12 | ≥12 | ≥13 |

| Reduction of area ,% | ≥40 | ≥40 | ≥45 | ≥50 | ≥50 |

| impact,J | - | ≥35 | ≥40 | ≥40 | ≥40 |

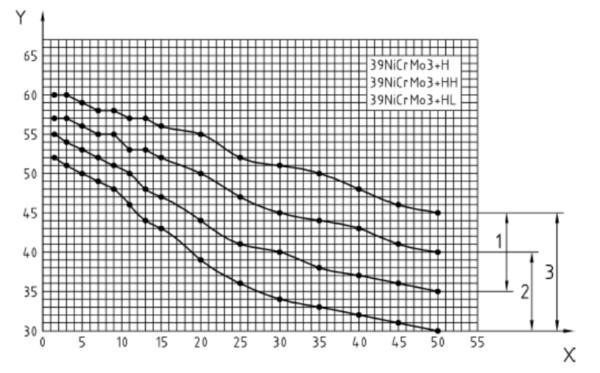

Jominy Quenching Test Curve For 39NiCrMo3 Steel

Quenching at 850°C

X:Distance from quenched end,in mm

Y:Hardness,HRC

1: HH level

2: HL level

3: H level

| HRC-mm | Type | 1.5 | 3 | 6 | 7 | 9 | 11 | 13 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 |

| MIN | +H | 52 | 51 | 50 | 49 | 48 | 46 | 44 | 43 | 39 | 36 | 34 | 33 | 32 | 31 | 30 |

| MAX | 60 | 60 | 59 | 58 | 58 | 57 | 57 | 56 | 55 | 52 | 51 | 49 | 48 | 46 | 45 | |

| MIN | +HH | 55 | 54 | 53 | 52 | 51 | 50 | 48 | 47 | 44 | 41 | 40 | 38 | 37 | 36 | 35 |

| MAX | 60 | 60 | 59 | 58 | 58 | 57 | 57 | 56 | 55 | 52 | 51 | 49 | 48 | 46 | 45 | |

| MIN | +HL | 52 | 51 | 50 | 49 | 48 | 46 | 44 | 43 | 39 | 36 | 34 | 33 | 32 | 31 | 30 |

| MAX | 57 | 57 | 56 | 55 | 55 | 53 | 53 | 52 | 50 | 47 | 45 | 44 | 43 | 41 | 40 |

WHAT WE SUPPLY FOR 39NiCrMo3 STEEL

Hot Forged Round bar:Φ80-Φ1000mm

Hot Rolled Round bar:Φ16-Φ130mm

Hot Forged Square bar: Max Thickness:500mm

Flat bar/Blcoks:Thickness :120-800mm ,Width:120-1500mm

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |