AS a low alloy high strength steel,30CND8 steel contains 2% Cr and 2% Ni elements as strengthening alloy elements as per French Standard NF A35-556.

30CND8 steel has high yield strength, tensile strength and fatigue strength, as well as sufficient plasticity and toughness after quenched and tempered condition.

Due to its excellent comprehensive performance, 30CND8 is often used in the production of high-end mechanical parts, such as screws, robotic arms, pistons, shafts, etc. In addition, 30CND8 steel is also used in occasions where product wear is high. The excellent corrosion resistance of 30CND8 steel makes it a very useful material in the oil and gas industry, aviation, mechanical engineering, chemical industry and shipbuilding.

WHAT IS 30CND8 STEEL?

NF is the standard code for Norms Francaises, which is formulated by the French Association for Standardization (AFNOR). Next, we will introduce the representation method of alloy steel under the NF standard.

XX OOO XX

1.XX represents the carbon content, expressed as C%x100.

2.OOO stands for alloying element symbol, the specific meaning is shown in Table 1 below

3.XX represents the content of each alloy element, which is expressed by multiplying the actual average content percentage of the main element by the index of the element listed in Table 1.

| Table 1 | |||||

| Alloy element | Symbol | Index | Alloy element | Symbol | Index |

| Cr | C | 4 | Sn | E | 10 |

| Co | K | 4 | Mg | G | 10 |

| Mn | M | 4 | Mo | D | 10 |

| Ni | N | 4 | P | P | 10 |

| Si | S | 4 | Pb | Pb | 10 |

| Al | A | 10 | W | W | 10 |

| Be | Be | 10 | V | V | 10 |

| Cu | U | 10 | Zn | Z | 10 |

Remark:

If the content of the main alloying elements in the steel is lower than the following conditions, it is not necessary to indicate the steel grade.

- Mn and Si < 1.2%

- Ni <0.2%

- Cr <0.25%

- Mo<0.1%

- V<0.05%

From the above content, we can easily know that in 30CND8 steel, 30 means the average carbon content is 0.30%, the average content of Cr and Ni elements is 8/4=2%, and it contains not less than 0.1% Mo element ( Actual: 0.3-0.5%)

30CND8 STEEL CHEMICAL COMPOSITION

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo |

| 30CND8 | 0.26-0.33 | 0.1-0.4 | 0.30-0.60 | ≤0.03 | ≤0.025 | 1.8-2.2 | 1.8-2.2 | 0.3-0.5 |

30CND8 STEEL RELATED STANDARD & EQUIVALENT GRADE

CHINA | GB 3077:30Cr2Ni2Mo

Europe | EN10083:30CrNiMo8

UK | BS970:823M30

30CND8 STEEL FORGING

- Initial Forging Temperature:1180-1220℃

- Final Forging Temperature:800℃

- Heating Rate:Strictly control the heating speed, which should be uniform and stable to prevent cracking caused by improper heating.

- Forging Ratio:above 4:1

- Post-Forging Treatment:30CND8 steel is highly sensitive to white point,and it needs to be dehydrogenated at a temperature of 630-660℃ immediately after forging.

30CND8 STEEL HEAT TREATMENT

Critical Temperature for Heat Treatment of 30CND8 Steel

- Ac1:740℃

- Ac3:810℃

- Ms:320℃

Temperature Selection for Conventional Heat treatment for 30CND8 Steel

- Soft Annealing:650 – 690°C,Cooling in furnace,hardness below 248 HBW

- Normalizing:850-900°C

- Oil Quenching:830-860°C

- Tempering:530-630°C

30CND8 Steel Mechanical Property at 20oC for Forged parts in Quenched & Tempered condition

| Diameter mm | ≤250 | 250-500 | 500-1000 |

| Tensile Strength Mpa | 880-1080 | 830-980 | 780-930 |

| Yield Strength Mpa | ≥685 | ≥635 | ≥590 |

| Elongation % | L:≥12 T:≥10 | L:≥12 T:≥10 | L:≥12 T:≥10 |

| Impact Charpy J | L:≥45 T:≥34 | L:≥45 T:≥34 | L:≥45 T:≥34 |

30CND8 Steel 0.2% Yield Strength vs Different High Temperature in Quenched & Tempered condition

| 0.2% Yield Strength or Yield Point Mpa,Min | |||||||

| Diameter mm | 20℃ | 100℃ | 200℃ | 250℃ | 300℃ | 350℃ | 400℃ |

| ≤250 | ≥685 | ≥657 | ≥628 | ≥598 | ≥559 | ≥520 | ≥481 |

| 250-500 | ≥635 | ≥608 | ≥579 | ≥549 | ≥510 | ≥471 | ≥431 |

| 500-1000 | ≥590 | ≥559 | ≥530 | ≥500 | ≥471 | ≥431 | ≥392 |

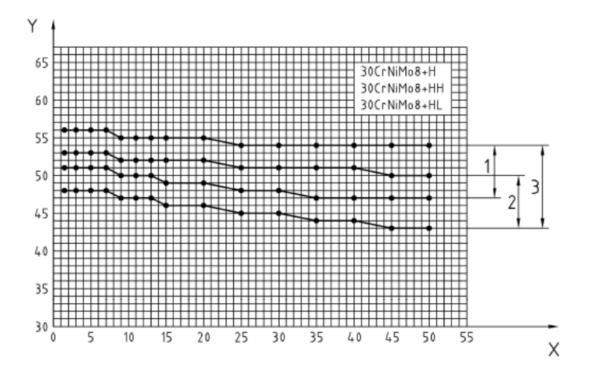

Jominy Quenching Test Curve For 30CND8 Steel

Quenching at 850°C

X:Distance from quenched end,in mm

Y:Hardness,HRC

1: HH level

2: HL level

3: H level

| HRC-mm | Type | 1.5 | 3 | 6 | 7 | 9 | 11 | 13 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 |

| MIN | +H | 48 | 48 | 48 | 48 | 47 | 47 | 47 | 46 | 46 | 45 | 45 | 44 | 44 | 43 | 43 |

| MAX | 56 | 56 | 56 | 56 | 55 | 55 | 55 | 55 | 55 | 54 | 54 | 54 | 54 | 54 | 54 | |

| MIN | +HH | 51 | 51 | 51 | 51 | 50 | 50 | 50 | 49 | 49 | 48 | 48 | 47 | 47 | 47 | 47 |

| MAX | 56 | 56 | 56 | 56 | 55 | 55 | 55 | 55 | 55 | 54 | 54 | 54 | 54 | 54 | 54 | |

| MIN | +HL | 48 | 48 | 48 | 48 | 47 | 47 | 47 | 46 | 46 | 45 | 45 | 44 | 44 | 43 | 43 |

| MAX | 53 | 53 | 53 | 53 | 52 | 52 | 52 | 52 | 52 | 51 | 51 | 51 | 51 | 50 | 50 |

WHAT WE SUPPLY FOR 30CND8 STEEL

Hot Rolled Round bars

- Dia 16-200mm daily stock wih 600+tons round bars

- Annealed/Q&T(pre hardened)condition for 5 days delivery available

- Bright steel with QT condition for 10 days delivery available

- Cut to length service available

Hot Forged bars

- Daily stock ingots to meet customer urgent order needs

- Dia 80-1000mm full size forging available

- Square/Flat/Blocks/Shafts customized production

- One-stop machining service

- Guaranteed inspection and testing