28Mn6/DIN 1.1170 steel is an unalloyed structural steel containing 1.5% manganese as per EN 10250 and EN 10083 standard.

28Mn6 steel has high hardenability and small quenching deformation, but has overheating, decarburization sensitivity and temper brittleness. 28Mn6 steel has medium plasticity during cold deformation, and its machinability and weldability are acceptable, but the material needs to be preheated to above 200°C before welding.

28Mn6 steel is generally supplied in a quenched and tempered or normalized condition.

28Mn6 STEEL CHEMICAL COMPOSITION

| Grade | C | Si | Mn | P | S | Cr | Mo | Ni |

| 28Mn6/1.1170 | 0.25-0.32 | ≤0.4 | 1.30-1.65 | ≤0.035 | ≤0.035 | ≤0.4 | ≤0.1 | ≤0.4 |

| Remark:Cr+Ni+Mo≤0.63% | ||||||||

28Mn6 STEEL RELATED STANDARD & EQUIVALENT GRADE

CHINA/GB 3077:30Mn2

UK/BS970:150M28

USA/ASTM A29:1330

JAPAN/JIS G4053:SMn433

28Mn6 STEEL PHYSICAL PROPERTY

| Density, g/cm3 | 7.86 |

| Melting point,℃ | 1420 |

| Specific heat capacity,(0~100℃),J/(kg.k) | 469 |

| Elastic Modulus,Mpa | 206035 |

| Shear modulus,Mpa | 79237 |

| Linear expansion coefficient,10^-6/k | 12.23 |

| Poisson’s ratio | 0.3 |

| Thermal conductivity,W/(m.K) | 35(100℃) |

28Mn6 STEEL FORGING

- Initial Forging Temperature:1150℃

- Final Forging Temperature:800-850℃

- Forging Ratio:above 4:1

- Post-Forging Treatment:As non-alloy steel, 28Mn6 steel should be slowly cooling in sand after forged.

28Mn6 STEEL HEAT TREATMENT

Critical Temperature for Heat Treatment of 28Mn6 Steel

- Ac1:713℃

- Ac3:793℃

- Ar1:630℃

- Ar3:710℃

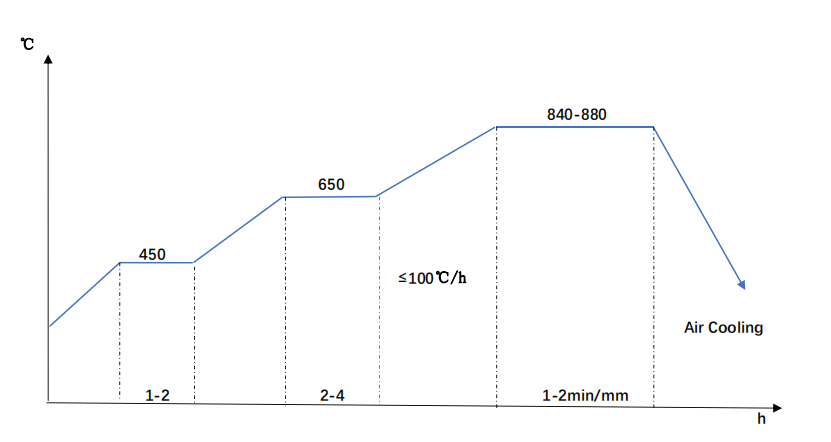

28Mn6 Steel Normalizing

- Heating temperature:840-880℃

- Heating time:The holding time is determined according to the thickness of the material.

- Cooling:Air cooling

28Mn6 Steel Normalizing Diagram

28Mn6 Steel Mechanical Properties in Normalized condition

| Normalizing Temperature | Tensile Strength | Yield Strength | Elongation | Reduction of Area | Impact Charpy-V |

| 870℃ | ≥600Mpa | ≥350Mpa | ≥15% | ≥45% | ≥80 |

28Mn6 Steel Quenching & Tempering(Q&T)

Process Details

- Quenching Temperature:820-840ºC/water,840-880ºC/oil

- Quenching Medium: Oil/Water

- TemperingTemperature:400-600ºC

- Cooling Medium:Air

28Mn6 Steel Mechanical Property with Quenched and Tempered Condition

| Tensile Strength Mpa | Yield Strength Mpa | Elongation % | Reduction of Area % | Impact Charpy-V J |

| ≥750 | ≥600 | ≥12 | ≥45 | ≥80 |

| Remark: Water quenching at 840ºC,Tempering at 500ºC,air cooling | ||||

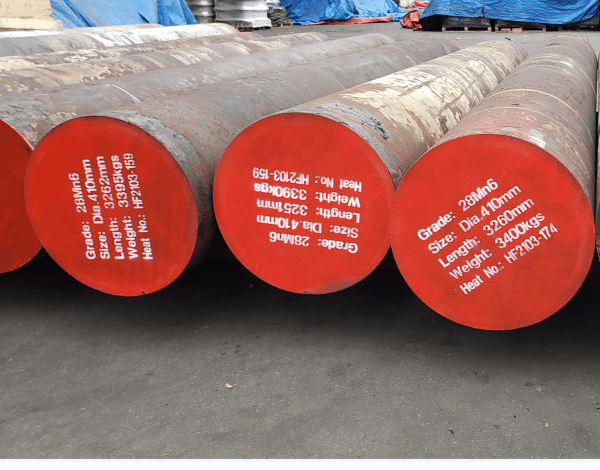

28Mn6 STEEL SUPPLY FORM & SIZE & TOLERANCE

Hot Forged Round bar:Φ80-Φ1000mm

Hot Rolled Round bar:Φ16-Φ130mm

Hot Forged Square bar: Max Thickness:500mm

Flat bar/Blcoks:Thickness :120-800mm ,Width:120-1500mm

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |

28Mn6 STEEL APPLICATIONS

28Mn6 steel is used after quenching and tempering, and has high strength, toughness and wear resistance, and good static strength and fatigue strength.It is often used as an important fastener with small cross-section, as well as frame beams, gearbox gears, shafts, cold heading bolts and quenched and tempered parts with large cross-sections.

In addition, 28Mn6 steel can also be used as carburized steel to make carburized parts with high core strength requirements, such as rear axles and journals of mining cranes.