D2 steel is a high-carbon, high-chromium cold-working tool steel (containing about 1.5% carbon and 12% chromium). It is widely used in industry for its excellent wear resistance, compressive strength and moderate corrosion resistance. The following are its main application areas and characteristics:

D2 Steel’s Diverse Industrial Applications

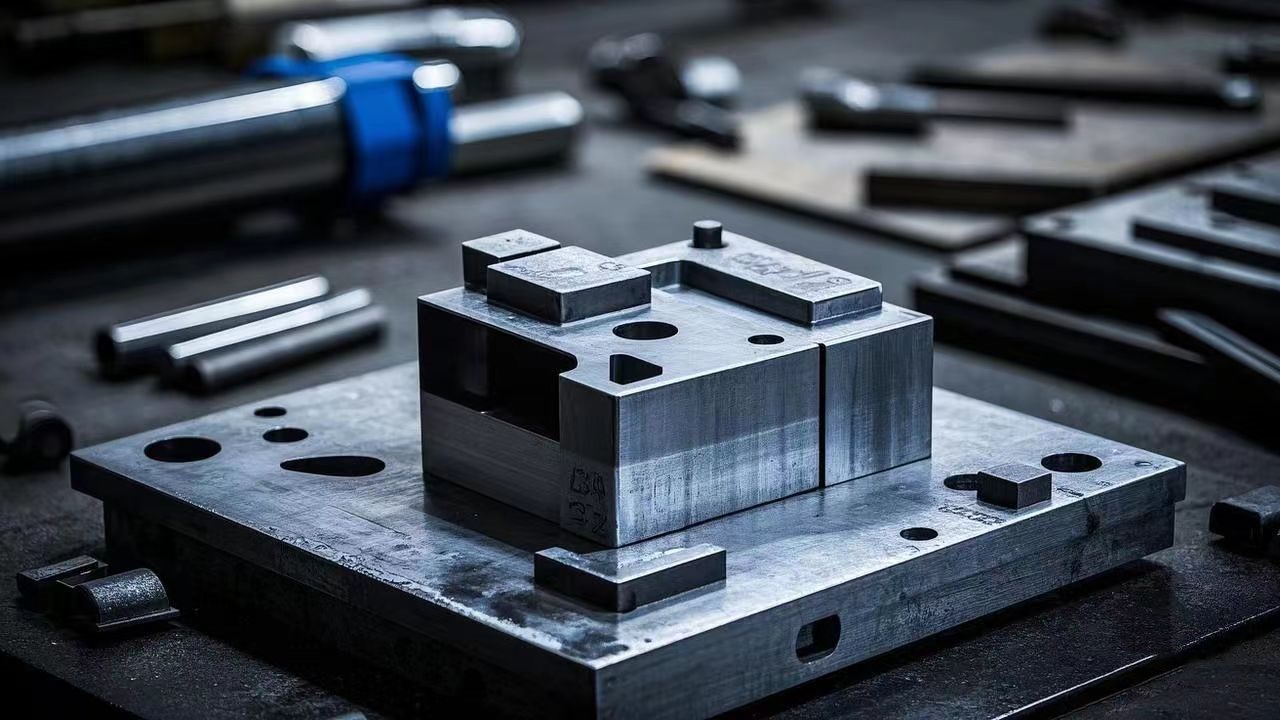

1. Mold Manufacturing

- Cold working molds: D2 steel is widely used to make stamping dies, cold heading dies, drawing dies and shear blades. Its high wear resistance can withstand high pressure impact and repeated friction of metal sheets, extending the life of the mold.

- Precision molds: High hardness (HRC 60-62 after heat treatment) and dimensional stability are suitable for precision molding, such as electronic connector dies or automotive parts molding dies.

2. Cutting tools and knives

- Industrial knives: Used to make tools for cutting high-hardness materials, such as milling cutters, drill bits and saw blades, but it should be noted that its red hardness (ability to maintain hardness at high temperatures) is not as good as high-speed steel, suitable for medium and low speed cutting.

- Wear-resistant blades: Such as paper/plastic slitting knives, woodworking knives, their wear resistance reduces the need for frequent replacement.

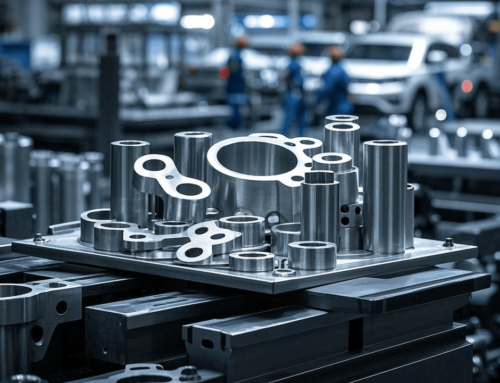

3. Automobile and mechanical parts

- Wear-resistant parts: Used to make bearings, guide rails, gears and other parts that are subject to high wear, such as engine valve guides or transmission parts.

- Gauges and fixtures: High hardness and stability are suitable for precision measuring tools (such as plug gauges) or fixture positioning blocks.

4. Plastic molding molds

- High-finish molds: D2 steel has a low surface roughness after polishing, which is suitable for injection molds of transparent plastic parts (such as optical lenses and cosmetic packaging) to reduce product surface defects.

- Glass fiber reinforced plastic molds: Wear resistance can resist the wear of glass fiber and extend the life of the mold.

5. Wear-resistant parts and tools

- Punches and dies: Excellent performance in metal punching and blanking processes, especially when processing stainless steel or high-strength alloys.

- Industrial rollers: Used for cold-rolled thin plates or strips, and the surface hardening improves wear resistance.

6. Special application scenarios

- Corrosion protection demand scenarios: Compared with ordinary tool steels (such as T10), D2 steel has a certain corrosion resistance due to its 12% chromium content and can be used in humid environments (regular maintenance or coating treatment is required).

- High-precision parts: such as watch parts or precision instrument parts, deformation is controlled by heat treatment to ensure dimensional accuracy.

Key performance advantages of D2 steel

- Wear resistance: High carbide content (chromium carbide) provides excellent wear resistance.

- Heat treatment performance: It can be hardened by oil quenching or air cooling, and maintains high hardness after tempering (recommended tempering temperature 180-250°C).

- Polishability: Fine structure is easy to polish to a mirror effect.

Limitations & Precautions For D2 Steel

- Low toughness: Not suitable for high impact load scenarios (such as hammer tools), and stress concentration design should be avoided.

- Limited corrosion resistance: Although better than ordinary steel, surface treatment (chrome plating, PVD coating, etc.) is still required in highly corrosive environments.

- Processing difficulty: High hardness increases machining costs, and it is usually necessary to process in the annealed state and then heat treat.

Alternative Material Selection For D2 Steel

- Higher toughness requirements: DC53 (modified D2 steel, improved toughness) or A2 tool steel can be selected.

- High temperature applications: Use high-speed steel (such as M2) or powder metallurgy steel (such as CPM 3V).

- Highly corrosive environment: Use stainless steel tool steel (such as 440C or S7).

Summary

D2 steel occupies an important position in the field of cold working dies, precision tools and wear-resistant parts due to its wear resistance and hardness, but its toughness and corrosion resistance limitations need to be weighed against specific working conditions, and performance can be optimized through heat treatment or surface treatment when necessary.