1. Material Properties Overview

8620 steel (SAE/AISI 8620) is a nickel-chromium-molybdenum alloy carburizing steel known for its excellent surface hardening ability and core toughness. Its characteristics make it widely used in components that need to withstand both surface wear and internal impact loads.

- Chemical composition (typical values):

– Carbon (C): 0.18-0.23% (low carbon core ensures toughness)

– Nickel (Ni): 0.40-0.70% (improves toughness and hardenability)

– Chromium (Cr): 0.40-0.60% (enhances surface hardening ability)

– Molybdenum (Mo): 0.15-0.25% (refines grains and improves high temperature performance)

– Manganese (Mn): 0.70-0.90% (deoxidation and solid solution strengthening) - Mechanical properties (after carburizing + quenching):

– Surface hardness: HRC 58-62 (carburized layer)

– Core hardness: HRC 28-35 (maintains toughness)

– Tensile strength: 850-1000 MPa

– Yield strength: 650-800 MPa

– Impact energy (-20℃): ≥40 J

2. Core Application Areas

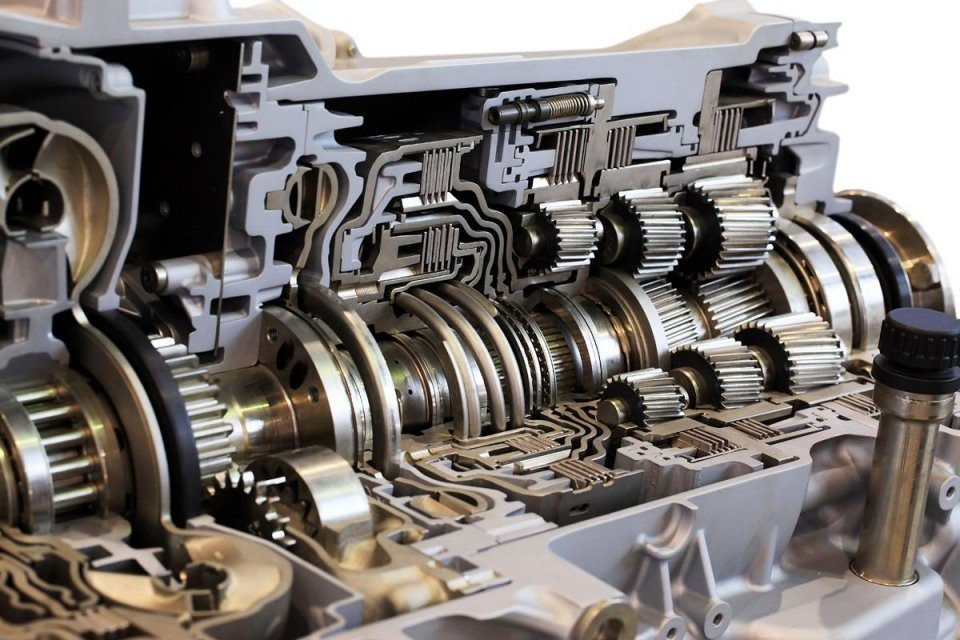

(1) Automobile industry

- Gearbox gears (such as main reduction gears, synchronizer gear rings):

– Requirements: surface wear resistance (contact fatigue strength ≥ 1500 MPa), core impact resistance.

– Process: carburizing (930℃×8h, carbon potential 1.1%) → direct quenching (oil cooling) → low temperature tempering (180℃×2h).

– Case: A certain automatic transmission gear, carburizing layer depth 1.2 mm, life of 300,000 kilometers. - Camshaft and crankshaft:

– Function: control valve opening and closing, withstand periodic bending stress.

– Design points:

– Core quenching and tempering treatment (tensile strength ≥ 800 MPa).

– Cam surface laser quenching (hardness HRC 60, hardened layer 0.8 mm). - Differential planetary gear:

– Challenge: Tooth surface pitting under high torque.

– Countermeasures: Shot peening after carburizing (surface residual compressive stress -600 MPa), fatigue life increased by 50%.

(2) Heavy machinery and engineering equipment

- Mining machinery gears (such as crusher gears, excavator slewing gear rings):

– Working conditions: impact load + abrasive wear.

– Process: deep carburizing (layer depth 2.0-2.5 mm), surface hardness HRC 60-62.

– Case: A cone crusher gear, the service life is 3 times longer than ordinary steel. - Hydraulic pump drive shaft:

– Requirements: high torsional strength (shear strength ≥ 500 MPa) + wear-resistant spline.

– Solution: high-frequency induction hardening of the spline part (hardness HRC 58, layer depth 1.0 mm).

(3) Energy and wind power equipment

- Planetary gears of wind turbine gearboxes:

– Challenge: micropitting and spalling under a design life of 20 years.

– Process:

– Vacuum carburizing (carburizing layer uniformity ± 0.05 mm).

– Surface plating with diamond-like carbon coating (DLC, friction coefficient ≤ 0.1). - Oil drilling tools (such as drill collar short sections):

– Function: transmit drilling torque and withstand downhole vibration.

– Design: core strength ≥700 MPa, surface nitriding (hardness HV 900) to resist mud erosion.

(4) Aerospace and military industry

- Helicopter main rotor gear:

– Requirements: high reliability (failure probability ≤10⁻⁶), lightweight.

– Process:

– Isothermal quenching after carburizing (bainite structure, fracture toughness KIC ≥80 MPa√m).

– Precision grinding (tooth shape error ≤3 μm). - Armored vehicle track pin:

– Working conditions: high impact + sand and dust wear.

– Solution: 8620 steel boronizing treatment (surface hardness HV 1800, wear resistance increased by 5 times).

3. Key Technologies For Processing & Heat Treatment

(1) Carburizing process

- Gas carburizing:

– Temperature: 925-930℃, carbon potential 0.8-1.2%, time depends on the layer depth requirement (0.5 mm requires 4h, 1.5 mm requires 12h).

– Cooling: direct oil quenching (60℃ quenching oil), reduce oxidation. - Vacuum carburizing:

– Advantages: no grain boundary oxidation (IGO≤5 μm), carburized layer uniformity ±0.03 mm, suitable for precision gears.

(2) Welding and repair

- Difficulty: Carburized layer welding is prone to cracks.

- Solution:

– Annealing before welding (reduce surface carbon content).

– Use nickel-based welding materials (such as ERNiCrMo-3), preheating to 200℃. - Case: After local repair of the gear, the hardness recovered to HRC 58, and the service life reached 80% of the new part.

(3) Machining optimization

- Rough machining:

– Tool: coated carbide (TiAlN), cutting speed 80-120 m/min.

– Cooling: water-based emulsion to avoid material softening. - Fine machining:

– Grinding: CBN grinding wheel, surface roughness Ra≤0.2 μm (gear tooth surface).

– Honing: tooth profile accuracy reaches DIN 3.

4. Engineering Challenges & Innovative Solutions

Carburizing deformation control:

- Problem: Thin-walled gears warp after carburizing (deformation ≥ 0.1 mm).

- Countermeasures:

– Use press quenching process (die pressure quenching, deformation ≤ 0.02 mm).

– Simulate and optimize furnace loading method (reduce thermal stress gradient).

Environmentally friendly alternative processes:

- Problem: Traditional carburizing has high carbon emissions (about 2 kg CO₂/kg steel).

- Innovation:

– Plasma carburizing (energy consumption reduced by 40%, permeation rate increased by 30%).

– Bio-based quenching medium (biodegradable vegetable oil instead of mineral oil).

Extreme environment applications:

- Problem: -50℃ low temperature brittleness of polar equipment.

- Solution:

– Optimize nickel content (Ni 0.8-1.0%), and increase impact energy to 60 J (-50℃).

– Surface zinc-nickel alloy (lower corrosion temperature limit -70℃).

5. Comparison With Other Carburizing Steels

| Materials | Carburized layer hardness (HRC) | Core toughness (impact energy) | Cost (relative to 8620) | Typical application scenarios |

| 8620 | 58-62 | ≥40 J (-20℃) | 1.0x | Automobile gears, heavy-duty transmission parts |

| 20MnCr5 | 58-60 | ≥35 J (-20℃) | 0.7x | Economical gearbox gears |

| 9310 | 60-63 | ≥30 J (-20℃) | 2.5x | Aircraft engine gears |

| 16MnCr5 | 56-58 | ≥45 J (-20℃) | 0.8x | Agricultural machinery gears, general parts |

6. Future Development Trends

- Digital carburizing control:

– AI-based carburizing model, real-time adjustment of carbon potential and temperature, layer depth control accuracy ±0.01 mm. - Composite surface treatment:

– Carburizing + physical vapor deposition (PVD) TiAlN coating, friction coefficient reduced to 0.05. - Additive manufacturing applications:

– Laser powder bed fusion (LPBF) manufacturing of complex gears, grain size refined to 5 μm, fatigue strength increased by 20%.

Summary

8620 steel has become a core material in the automotive, heavy industry, energy and other fields due to its excellent balance between carburizing performance and core toughness. Through precision carburizing, deformation control and surface strengthening technology, the wear resistance and fatigue life of key components can be significantly improved.

In the future, combined with green manufacturing and digital technology, 8620 steel will continue to promote the development of high-reliability equipment to meet the needs of industrial upgrading.