ABOUT FUHONG

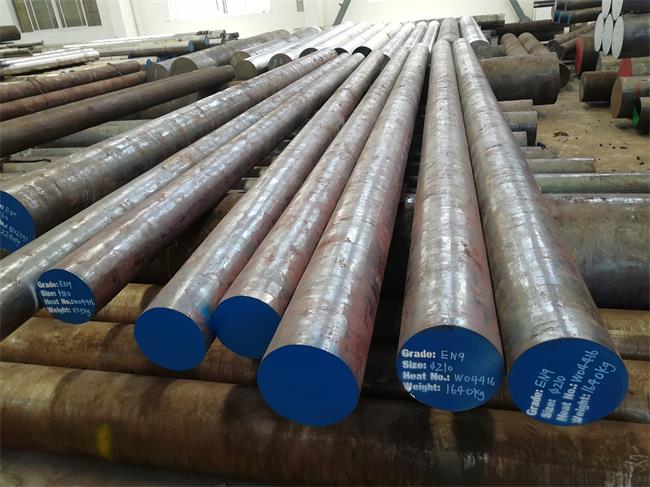

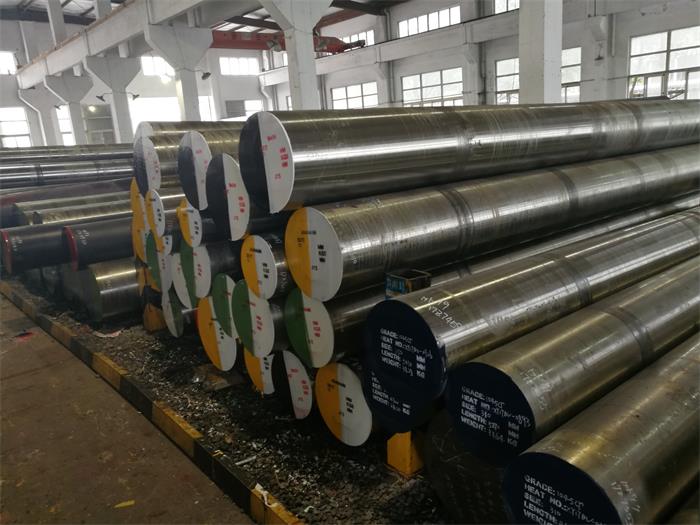

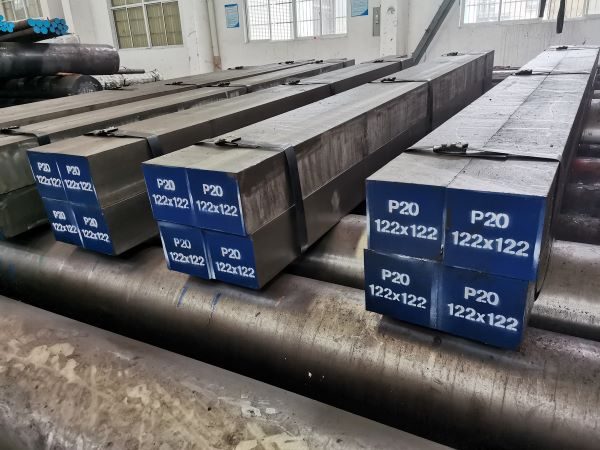

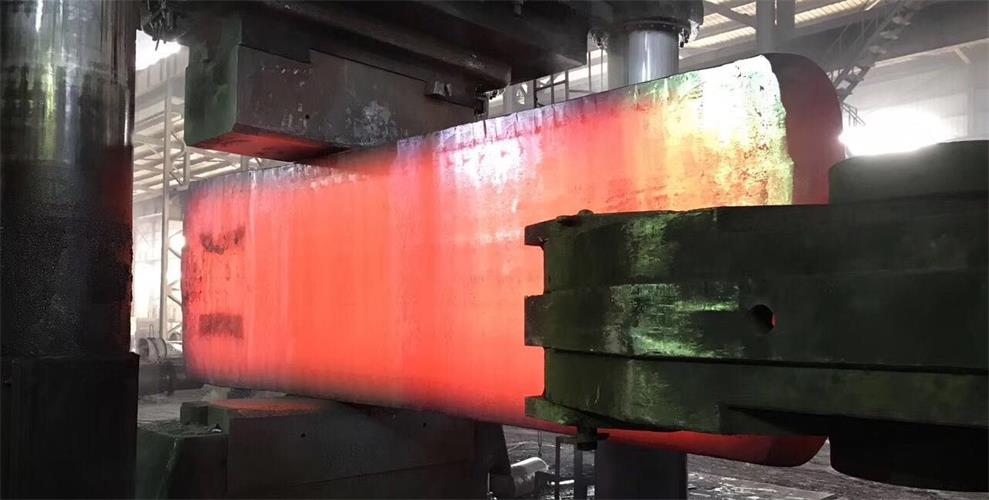

Established in 2005,We are committed to becoming one of the leading special steel exporter and supplier,and aim to be total solution provider regarding quality special steel materials and related products. We supply a wide range of engineering steel,tool steel and other special steel products in round,flat,square,tube,shaft and other various shapes, which are widely applied in petrochemicals, automobile, machinery, power and bearing industry.

Compliance with strict quality control and quality management system,we are sticking to offer customers one-stop service and integrated supply chain solutions which including heat treatment,cutting,machining and other value-added service.

In belief of “Result Driven and Customer Focus”, we are not only delivering qualified special steel materials, but also delivering competitive advantage to all of customers based on the business principle of win-win cooperation.Win-win by Continuous Fuhong, achieve Win-Win by Continuous Cooperation with every business partner.

OUR CORE VALUES. OUR BELIEFS.

Result Driven—Working hard towards our goals to achieve results for every task.

Sustainability—Pursing long-term strategic development instead of short-term profits.

Win-win Cooperation—Achieving Win-win status by mutual cooperation.

Customer Focus—Customer’s satisfaction is the basis of our existence and success.

Partnership—Seeking partnership to develop lasting/profitable relationships with customers.

Competence—Not only delivering material but also delivering competence and continuous improvement to customer.

Openness&Initiative—Listening to improvement proposals from everybody towards changes and innovation.

Honesty&Integrity—Being honest whenever to win respect from customers and other cooperation parties.

Teamwork— Everybody plays a role in the company’s success through team work.

DO YOU PRIORITIZE WHAT WE DELIVER?

WE BELIEVE

WE DON’T BELIEVE IN SHORTCUTS !

OUR EXPERIENCES. OUR ADVANTAGES.

We have rich experience in handling orders for customers with professional process.

AVAILABLE IN ALL PRODUCT VARIATIONS

ARE WE THE RIGHT 'FIT' FOR YOU?

IT IS NOT BECAUSE

How good we are boasting or how cheap our products seems to be

IT IS BECAUSE

Our offer bridges your needs and our solution addresses your pain

Our product is able to achieve your desired result and performance

Our market positioning matches yours and our commitment resonates with you

Our competence to work out a proposal that springs a “before Vs after” clears your worries

Our market performance and customer referral allows for your joined trust