EN19 steel Manufacturer and Exporter,supplied with round,square,flat,block,and shaft etc.

EN19/709M40,containing 1% Chromium-Molybdenum elements,is widely used as alloy engineering steel.It will get high tensile strength combined with good ductility,shock resistance and good wear resistance after heat treatment.EN19 steel is usually supplied with annealed condition(Max hardness below 248HB) after forged,and also suitable for quenched and tempered condition with tensile ranges of R(695-850Mpa),S(775-925Mpa),T(850-1000Mpa),U(925-1080Mpa),V(1000-1160Mpa),W(1080-1235Mpa),and Y(1235-1390Mpa).

1.Supply Form & Size & Tolerance

Hot Forged Round bar:Φ80-Φ1000mm

Hot Rolled Round bar:Φ16-Φ280mm

Hot Forged Square bar: Max Thickness:500mm

Flat bar/Blcoks:Thickness :120-800mm ,Width:120-1500mm

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |

2.Chemical Composition

| Grade | C | Si | Mn | P | S | Cr | Mo |

| EN19 | 0.35-0.45 | 0.10-0.35 | 0.5-0.8 | ≤0.05 | ≤0.05 | 0.9-1.5 | 0.2-0.4 |

| 709M40 | 0.36-0.44 | 0.1-0.4 | 0.7-1.0 | ≤0.035 | ≤0.04 | 0.9-1.2 | 0.25-0.35 |

EN19 Series For Speical Applications:EN19A,EN19B,EN19C.

| Grade | C | Si | Mn | P | S | Cr | Mo |

| EN19A | 0.35-0.45 | 0.10-0.35 | 0.5-0.8 | ≤0.05 | ≤0.05 | 0.9-1.2 | 0.2-0.35 |

| EN19B | 0.35-0.40 | 0.10-0.35 | 0.5-0.8 | ≤0.05 | ≤0.05 | 0.9-1.2 | 0.2-0.35 |

| EN19C | 0.40-0.45 | 0.10-0.35 | 0.5-0.8 | ≤0.05 | ≤0.05 | 0.9-1.2 | 0.2-0.35 |

3. Equivalent Grade

| USA | Germany | China | Japan | France | Russia |

| 4140 | 42CrMo4/1.7225 | 42CrMo | SCM440 | 42CD4 | 42HM |

4. Mechanical Property

Condition | Hardened & Tempered |

||||||

| R | S | T | U | V | W | Y | |

| Ruling Section,inch | 6 | 4 | 2 1/2 | 2 1/2 | 1 1/8 | 1 1/8 | 1 |

| Tensile Strength,Mpa,Min | 695 | 775 | 850 | 925 | 1005 | 1080 | 1235 |

| Yield Strength,Mpa,Min | 525 | 585 | 680 | 740 | 805 | 895 | 1050 |

| Elongation,Min | 22 | 20 | 18 | 17 | 16 | 15 | 10 |

| ISO V Impact,J,Min | 54 | 54 | 54 | 48 | 48 | 41 | 14 |

| Hardness,HBW | 201-255 | 223-277 | 248-302 | 269-321 | 293-341 | 311-375 | 363-415 |

0.2% Proof Stress tests value with Quenched & Tempered condition

| Property | R | S | T | U | V | W | Y |

| Proof Stress(0.2%) Mpa,Min | 495 | 555 | 635 | 710 | 775 | 850 | 990 |

5.Forging Steel

Recommended Forging temperature:850℃- 1150℃,and final forging temperature should not below 850℃.This material should be cooled as slowly as possible in still air or in sand after forged.

6.Heat Treatment

- Normalizing

Normalizing is used to refine the structure of forgings that might have cooled non-uniformly after forged,and considered as a conditioning treatment before final heat treatment.Normalizing temperature for EN19 steel should be carried out between 870℃-900℃ with several steps,keep proper holding time depend on the steel size for the steel to be thoroughly heated to complete the ferrite to austenite transformation.Cool in still air.

- Annealing

Annealing is generally applied after forged and before machining to reduce surface harness,and get finer grain,get good machinability.

Soft Annealing:Heat the steel to the temperaure 680℃-700℃,Holding temperature for the steel heating, Cool slowly in the furnace.

Full Annealing:Heat the steel to the temperaure 850℃ with three steps ,Holding temperature for the steel heating,Cool in furnace.Surface hardness after annealing will be below 248HB.

- Hardening

Hardening temperature is carried out from an austenitizing temperature of 850-880ºC with several steps,keep suitable time for the steel to be thoroughly heated, oil quenching is recommended.

- Tempering

Tempering process should be followed after quenching immediately.Tempering at a suitable temperature ranges of 550-720ºC

7.Application

With good performance,EN19 alloy engineering steel,is widely used in automotive ,oil & gas,and machine tool and motor industries and a wide variety of applications where a good quality high tensile steel grade is required.

Typical applications

- Automotive gears and parts

- Shatfs & axles

- Studs & Bolts

- Towing pins

EN19/709M40 STEEL BUYING GUIDE

EN19 steel, is the most commonly used Cr-Mo series low alloy steel in the UK, similar to AISI 4140 in the United States and 42CrMo4 in Europe.In the BS970 standard, it was first defined as EN19, which was later replaced by 709M40.

As one of the commonly used low alloy steel grades, how does it perform? In this guide, we will help you understand the knowledge and characteristics of EN19 steel, so as to help you better choose and buy it.

Let’s start from here.

WHAT IS EN19/709M40 STEEL?

EN19 belongs to the grades in the British BS970 standard. In the past, the British Standardization Institute (BSI) represented carbon steel, alloy steel, and stainless steel as “ENXX”, where XX was a number from 1 to 3 digits.and the number was not necessarily a sequence number, nor did it necessarily have a specific meaning.

Due to this representation method, the chemical composition of steel grades cannot be accurately expressed, and there is a lack of reasonable classification, especially the newly developed steel grades are difficult to insert. Considering these shortcomings, BSI has released a new numerical steel number system to replace the previous representation.Therefore, 709M40 uses a new representation method to replace EN19.

Next, we will specifically introduce this new digital steel number naming system as follows.

XXX O XX

The first X represents a number, the steel group category number.For specific meaning, see table 1

The second and third XX represent numbers, indicating the chemical composition of the characteristic or the serial number of the steel group.For specific meaning, see table 2

O stands for letter, indicating supply condition or material type

- A: The first letter of Analyse, indicating that the supply conditions are guaranteed chemical composition.

- M: The first letter of Mechanical, indicating that the supply conditions are guaranteed mechanical properties.

- H: The first letter of Hardenability, indicating that the supply condition is to ensure hardenability.

- S: The first letter of Stainless, which means stainless steel.

The last two XX, representing numbers, indicate the average carbon content.

| Table 1 | ||||

| 0 | 1 | 2 | 3 | 4 |

| Carbon steel | Stainless steel | |||

| Ordinary manganese steel | High manganese steel | Free cutting steel | Austenitic steel | Martensitic & Ferritic steel |

| Table 2 | |||

| 50 | Ni steel | 78 | MnNiMo steel |

| 52 | Cr steel,w(Cr)<1% | 80 | NiCrMo steel,w(Ni)<1% |

| 53 | Cr steel,w(Cr)≥1% | 81 | NiCrMo steel,w(Ni):1-1.5% |

| 60 | MnMo steel | 82 | NiCrMo steel,w(Ni):1.5-3% |

| 63 | NiCr steel,w(Ni)<1% | 83 | NiCrMo steel,w(Ni):3-4.5% |

| 64 | NiCr steel,w(Ni):1.1-2.5% | 87 | CrNiMo steel,w(Cr)>1% |

| 65 | NiCr steel,w(Ni):2.5-4.5% | 89 | CrMoV steel |

| 66 | NiMo steel | 90 | CrMoAl steel |

| 70 | CrMo steel,w(Cr)<1.1% | 92 | SiMnMo steel |

| 72 | CrMo steel,w(Cr)≥3% | 94 | MnNiCrMo steel |

| 73 | CrV steel | ||

From the above content, 709M40 is expressed as a CrMo alloy steel with a Cr content of about 1.1% and an average carbon content of 0.4%, and this steel guarantees the mechanical properties of the material.

IS EN19 STEEL SAME AS 4140 STEEL?

First of all, they are Cr-Mo series low alloy steels, secondly they are equivalent steel grades, 4140 is from ASTM A29 of American standard, and EN19 is from BS970 of British standard, but this does not mean that they can be used in place of each other.

| Grade | C | Si | Mn | P | S | Cr | Mo |

| EN19 | 0.35-0.45 | 0.10-0.35 | 0.5-0.8 | ≤0.05 | ≤0.05 | 0.9-1.5 | 0.2-0.4 |

| 4140 | 0.38-0.43 | 0.15-0.35 | 0.75-1.00 | ≤0.035 | ≤0.04 | 0.8-1.1 | 0.15-0.25 |

From the above table, we can see that they still have certain differences in chemical composition,especially on Mn and Cr alloying elements.As equivalent steel grades, EN19 and 4140 steels are not much different in terms of manufacturing, heat treatment, processing and application, and in terms of welding performance, both are poor, but EN19 is relatively better.

As for whether EN19 and 4140 steel can be used instead, in theory, it is only necessary to adjust the corresponding elements to the overlapping range, but in practice, considering the production cost, it is not recommended.

QUICK FAQS FOR EN19/709M40 STEEL

What is EN19 series Steel?

EN19 steel is classified as 1% chromium-molybdenum alloy steels in the BS970 standard.In order to meet the special application requirements of different customers, BS970 has added EN19 series steel, namely EN19A, EN19B, EN19C.

| Grade | C | Si | Mn | P | S | Cr | Mo |

| EN19 | 0.35-0.45 | 0.10-0.35 | 0.5-0.8 | ≤0.05 | ≤0.05 | 0.9-1.5 | 0.2-0.4 |

| EN19A | 0.35-0.45 | 0.10-0.35 | 0.5-0.8 | ≤0.05 | ≤0.05 | 0.9-1.2 | 0.2-0.35 |

| EN19B | 0.35-0.40 | 0.10-0.35 | 0.5-0.8 | ≤0.05 | ≤0.05 | 0.9-1.2 | 0.2-0.35 |

| EN19C | 0.40-0.45 | 0.10-0.35 | 0.5-0.8 | ≤0.05 | ≤0.05 | 0.9-1.2 | 0.2-0.35 |

From the above table, it can be seen that the chemical element range of EN19A, EN19B, EN19C can be covered by EN19, which means that they can be used instead of EN19 to play their special applications

What is EN19T Steel?

In the BS970 standard, the letters P to Z are used to indicate the varying tensile strength ranges for different specifications.

- P:550-700Mpa

- Q:625-775Mpa

- R:700-850Mpa

- S:775-925Mpa

- T:850-1000Mpa

- U:925-1075Mpa

- V:1000-1150Mpa

- W:1075-1225Mpa

- X:1150-1300Mpa

- Y:1225-1375Mpa

- Z:1500Mpa Min

For EN19T steel,T represents that the tensile strength of EN19 steel in the quenched and tempered condition reaches 850-1000Mpa.

Is EN19 steel suitable for water quenching or oil quenching?

EN19/709M40 steel is very suitable for quenching and tempering to obtain excellent comprehensive mechanical properties.The quenching medium is water or oil, which needs to be determined according to the specific conditions of the material. The hardness after water quenching is higher than that after oil quenching, but oil quenching is milder and less stressful than water quenching.

As long as the specific application requirements of EN19 steel are achieved through a reasonable quenching process, both water quenching and oil quenching are suitable.

What is hardness of EN19 Steel?

The hardness of EN19 steel can be achieved by heat treatment.

After annealing, the hardness of EN19 steel is usually lower than 229HBW, which is convenient for machining.

Generally, EN19 steel can obtain good hardness and strength after quenching and tempering.Under the condition of T, the tensile strength is 850-1000Mpa, and the corresponding hardness is 248-302HBW.

To further increase the hardness, EN19 steel can also be obtained by nitriding.After nitriding, the surface hardness of EN19 steel can reach 550-700HV, and the nitration hardness depth is 0.1-0.6mm.

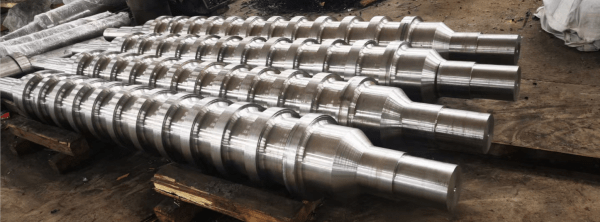

Is EN19 Steel suitable for Shafts?

The main function of the shaft is to support the rotating parts and transmit motion and power, and generally bear the bending moment and torque, which requires the material of the shaft to have good strength and hardness.

EN19 steel has excellent performance after quenching and tempering which is suitable for shaft products. It is often used to make mechanical shafts,Steel rolling roller etc.

WHAT IS THE DIFFERENCE BETWEEN EN19 AND EN9 STEEL?

EN9 and EN19 are from the old version of BS970, we can’t see any difference from the name alone. But after the revision of BS970, EN9 corresponds to 070M55, EN19 corresponds to 709M40, we can clearly see the difference.

- Different types of steel

EN9 and EN19 belong to different steel grade categories, EN9 belongs to carbon structural steel, while EN19 belongs to alloy structural steel.This is the most essential difference between the.For details, please see the chemical composition comparison table below.

| Grade | C | Si | Mn | P | S | Cr | Mo |

| EN19 | 0.35-0.45 | 0.10-0.35 | 0.5-0.8 | ≤0.05 | ≤0.05 | 0.9-1.5 | 0.2-0.4 |

| EN9 | 0.5-0.6 | 0.05-0.35 | 0.5-0.8 | ≤0.06 | ≤0.06 | - | - |

- Dfferent manufacturing costs

EN9 as carbon steel has no alloying elements compared to EN19 alloy steel, while EN19 steel contains about 0.9-1.5% Cr and 0.2-0.4% Mo.This makes EN19 steel significantly more expensive to manufacture than EN9 steel.

- Difficulty of weldability

An important indicator to measure the difficulty of welding is carbon equivalent.According to the carbon equivalent formula CE=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15,both EN9 and EN19 steels have high CE values. According to experience, if CE is greater than 0.5, the welding performance is poor. However, the welding performance of EN19 is relatively better.

However, when welding these two materials, preheating before welding and post-welding heat treatment are required, which are strictly implemented in accordance with the welding process.

- Different applications

EN9 is a high-strength medium-carbon steel. It has high surface hardness and strength after heat treatment, but poor plasticity and toughness. It is generally used for parts that require high strength and wear resistance or elasticity, dynamic load and impact load , such as gears, rims, flat springs, crankshafts, etc.

While EN19 as a low alloy structural steel, it has higher fatigue strength,wear resistance,impact resistance, toughness and torsional strength after heat treatment.It is widely used in oil and gas industry, machine tool and motor industry and other fields. EN19 is suitable for applications such as shafts, gears, bolts, studs, etc., as well as various applications suitable for high-quality high-strength steel grades.

HOW TO CONTROL THE QUALITY OF EN19/709M40 STEEL?

The manufacture of EN19 steel is a strict quality control process. Whether each key point of quality control can be executed with high quality is related to the final performance of EN19 steel. Next, we focus on the following key points on this topic.

- Smelting Chemical Composition Control

The smelting chemical composition control of EN19/709M40 is controlled from two aspects. On the one hand, since EN19/709M40 steel is a steel that guarantees mechanical properties, the control of the main alloy should be controlled above the center line, such as the Cr content should be controlled at about 1.1%, and the Mo content should be controlled at about 0.3%.

On the other hand, the smelting control of harmful elements should be more strict, such as P, S elements. In the BS970 standard, the requirement is less than or equal to 0.05%, which can be said to be the most basic requirement. In the actual smelting process, we must strive to control it below 0.02%.

For gas content, this is also a top priority for control. We should strive to achieve the standards of O≤20ppm, N≤50ppm, H≤2ppm.

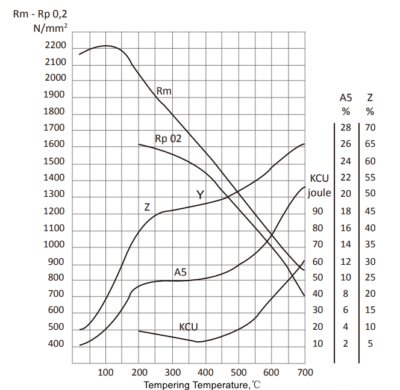

- Heat Treatment Process Control

Good heat treatment process control can significantly improve the material structure and maximize the performance of the material.For EN19/709M40 steel, its maximum performance can be achieved by quenching and tempering heat treatment.How to reasonably control the heating temperature, rate, holding time, quenching medium, quenching time, cooling speed and other factors have become the top priority.

- Heat Rate:Heating evenly and stably ensures that the material is thoroughly heated. Too fast or too slow is not suitable

- Quenching Temperature:860-890℃

- Quench Medium:Oil,Water

- Tempering Temperature:550-700℃

Mechanical property curves of EN19 steel at different tempering temperatures

In addition, EN19 steel through nitriding heat treatment is also a good choice. After a reasonable nitriding process, the surface hardness of EN19 can reach 550-700HV3, Nitration hardness depth 0.1-0.6mm.

- Internal Non-destructive testing

We certainly hope that the EN19 steel produced is free of internal defects, but the necessary inspections are still necessary.We can achieve the purpose of internal quality control of EN19 steel by means of non-destructive testing.The most commonly used detection method is ultrasonic testing, which is efficient, economical and highly repeatable.

In the manufacturing process of EN19 steel, such as after forging, before and after heat treatment, before and after machining, in the final product inspection stage, etc., ultrasonic testing will be highly expected to find macroscopic defects inside the material, such as looseness, cracks, inclusions, etc.The advantage of this aspect is very worthy of recognition, it can help us avoid further loss of time and money.

BUYING EN19/709M40 STEEL: WHICH SUPPLIER CAN YOU TRUST?

EN series steel is very popular in the Indian market and the UK. As the representative steel of CrMo series, EN19 has a wide range of applications, which determines the popularity of EN19 steel in the market.

In such a competitive market, we always insist on providing customers with high-quality EN19 steel, which has won the trust of customers.

What We Supply For EN19/709M40Steel

Hot Rolled Round bars

- Dia 14-350mm daily stock wih 2000+tons round bars

- Annealed/Q&T(pre hardened)condition for 5 days delivery available

- Bright steel with QT condition for 10 days delivery available

- Cut to length service available

Hot Forged bars

- Daily stock ingots to meet customer urgent order needs

- Dia 80-1000mm full size forging available

- Square/Flat/Blocks/Shafts customized production

- Conventional heat treatment service

- One-stop machining service