DIN1.6582/34CrNiMo6 steel Manufacturer and Exporter,supplied with round,square,flat,block,and shaft etc.DIN 1.6582/34CrNiMo6 a heat treatable, low alloy steel which contains chromium,molybdenum and nickel as strengthening agents as per BS EN 10083-3:2006. It is known for its good strength,toughness, hardenability and capability of developing high strength in the heat treated condition while retaining good fatigue strength,but it is poor in weldability,usually this steel should be hardened and tempered before application.

1.Supply Form & Size & Tolerance

| Supply Form | Size(mm) | Process | Tolerance | |

Round | Φ6-Φ100 | Cold Drawn | Bright/Black | Best H11 |

Φ16-Φ350 | Hot Rolled | Black | -0/+1mm | |

| Peeled/ground | Best H11 | |||

Φ90-Φ1000 | Hot Forged | Black | -0/+5mm | |

| Rough Turned | -0/+3mm | |||

Flat/Square/Block | Thickness :120-800 | Hot Forged | Black | -0/+8mm |

| Width:120-1500 | Rough Machined | -0/+3mm | ||

Remark:Tolerance can be customized as per requests

2.Chemical Composition

| Standard | Grade | C | Mn | P | S | Si | Ni | Cr | Mo |

| EN 10083 EN 10250 | 34CrNiMo6 | 0.30-0.38 | 0.50-0.80 | ≤ 0.025 | ≤ 0.035 | ≤ 0.4 | 1.3-1.7 | 1.3-1.7 | 0.15-0.3 |

| 1.6582 |

3.Physical Property

| Density, g/cm3 | 7.85 | ||||

| Specific heat capacity J/(kg.K) | 460 | ||||

| Electric resistivity Ohm.mm2 /m | 0.19 | ||||

| Electric conductivity Siemens.m/mm2 | 5.26 | ||||

| Modulus of elasticity Gpa | 100 ℃ | 200 ℃ | 300 ℃ | 400 ℃ | 500 ℃ |

| 205 | 195 | 185 | 175 | ||

| Thermal expansion 10^6 m/(m.K) | 100 ℃ | 200 ℃ | 300 ℃ | 400 ℃ | 500 ℃ |

| 11.1 | 12.1 | 12.9 | 13.5 | 13.9 | |

4. Mechanical Property

| Depth mm | 25 | 1/3 radius | 1/2 Diameter |

| R Mpa | 930 | 900 | 860 |

| Rp 0.2 Mpa | 828 | 750 | 730 |

| A % | 18.6 | 15.4 | 12.6 |

| C % | 64 | 60 | 46 |

| Kv +20 ℃ J | / | / | 70/74/70 |

| Kv -40 ℃ J | 110/110/118 | 48/44/45 | 25/28/25 |

| Hardness HB | 279 | 271 | 264 |

Longitudinal Tesing

Forged round bar Dia 520mm,Quenched at 870 ℃ in water,tempered at 630 ℃ in air.

5.Forging

DIN 1.6582/34CrNiMo6 forging temperature:850 – 1100°C

6.Heat Treatment

- Normalizing: 850 – 880°C,Cooling in air

- Soft Annealing:650 – 680°C,Cooling in furnace,Max Hardness:248HB

- Full Annealing:830-900°C,Cooling in furnace to 300°C

- Stress relieve:450-650°C ,appr. 50 °C under tempering temperature

- Hardening:830 – 860°C,Quenching in oil

- Tempering:540 – 660°C,Cooling in air

7.Application

DIN 1.6582/34CrNiMo6 steel is used to make tools which requires good plasticity and high strength. It is usually selected to make the big size and important parts, such as heavy machinery axle,turbine shaft blade, high load of transmission parts, fasteners, crank shafts, gears, as well as heavily loaded parts for motor construction etc.

34CrNiMo6/DIN 1.6582 STEEL BUYING GUIDE

When you need to buy 34crnimo6 steel, have you already understood some of its basic knowledge? Based on these, do you have the confidence to purchase qualified materials?

Is this enough? Of course not enough

From our guidance, we believe that we can help you, so as to help you select qualified materials and reliable suppliers step by step.In-depth understanding of what 34CrNiMo6 / 1.6582 steel is, this will be the topic we need to discuss next.

WHAT IS 34CRNIMO6 / DIN 1.6582 STEEL?

34CrNiMo6/DIN1.6582 Steel, as a representative of the Cr-Ni-Mo series of low-alloy steel, is included in the two European standards EN10083 and EN10250.

So the question is:Do we really understand the meaning of numbers and letters in steel grades when we use 34CrNiMo6 steel?

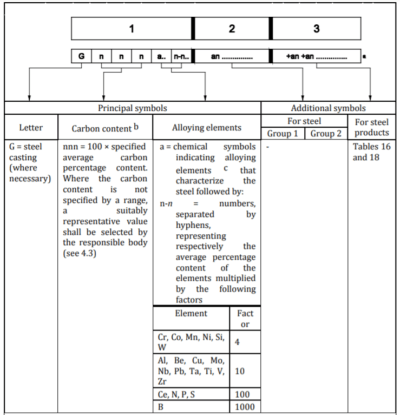

We can see the below Table 13 from EN10027 Standard:Designation systems for steels.

Key

1 = Principal symbols

2 = Additional symbols for steel

3 = Additional symbols for steel products

a n = numerical characters, a = alpha characters, an = alphanumeric characters.

b To distinguish between two similar steel grades, the number indicating carbon content may be increased by 1.

c The sequence of symbols shall be in decreasing order of the values of the average percentage content; where the values of contents are the same for two or more elements, the corresponding symbols shall be indicated in alphabetical order.

According to the above standard rules,we know that 34 in 34CrNiMo6 means that this steel has an average carbon content of 0.34%.While the average content of Cr and Ni is the same, each is 6/4=1.5%,and this steel has Mo,but the specific content is not mentioned.

GRADE COMPARISON:34CRNIMO6 VS EN24

34CrNiMo6/DIN 1.6582 is an European grade from EN10083 and EN10250 Standard,while EN24,also refers to 817M40, is a British grade from BS970.Both of these materials are widely used Cr-Ni-Mo series of low-alloy high-strength steels. Next, let’s first look at their chemical composition differences.

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo |

| EN24 | 0.35-0.45 | 0.10-0.35 | 0.45-0.7 | ≤0.05 | ≤0.05 | 0.9-1.4 | 1.3-1.8 | 0.2-0.35 |

| 817M40 | 0.36-0.44 | 0.1-0.4 | 0.45-0.7 | ≤0.035 | ≤0.04 | 1.0-1.4 | 1.3-1.7 | 0.2-0.35 |

| 34CrNiMo6/1.6882 | 0.30-0.38 | ≤ 0.04 | 0.50-0.80 | ≤ 0.025 | ≤0.035 | 1.3-1.7 | 1.3-1.7 | 0.15-0.3 |

From the above table,first of all, we can see that there is a little gap between the C and Cr elements, but they can be used instead of each other after technical adjustments. This has also been proven to be completely possible in actual application.

EN24 Steel is usually used in quenched and tempered condition, and mainly supplied with T condition, which refers to EN24T. You can see its mechanical performance requirements from the table below.

| Condition | Tensile Strength MPa | Yield Strength MPa | Elongation % | Impact,J | Hardness,HB |

| T | 850-1000 | ≥680 | ≥18 | ≥54 | 248-302 |

While 34CrNiMo6 steel generally has a quenched and tempered hardness of 28-32HRC, and its mechanical properties can reach the level of EN24T steel.

In summary, these two materials need to be used after quenching and tempering with high strength,toughness, good hardenability and anti-overheating stability,but it should be noted that they all have high white point sensitivity and temper brittleness.

In application,they can all be used for shafts and connecting rods that are subject to larger loads,and parts that are hard and wear-resistant on the surface and tough in the core, such as gears, shafts, pins ,etc.

QUICK FAQS FOR 34CRNIMO6 STEEL

Is DIN 1.6582 Steel Same As 34CrNiMo6 Steel?

Yes,DIN 1.6582 is same as 34CrNiMo6,they represent the same material.

Regarding the numerical code (W-Nr.), the method of designating grades is derived from the DIN 17007 standard and was proposed by the German Standards Committee.Nowadays,it is used in parallel with the letter-number naming system which is from the DIN 17006 standard.

For example:

34CrNiMo6 Steel Equivalent Grade

34CrNiMo6/DIN 1.6582, due to its superior performance, mainstream countries will also replace it with similar grades.Details as follows:

- USA-ASTM A29:4340

- UK-BS970:EN24/817M40

- CHINA-GB3077:34Cr2Ni2Mo

- JAPAN:JIS G4013:SNCM439

By the way, they are not completely equivalent to 34CrNiMo6, only have the same types of alloying elements.When we use them specifically, we still have to consider the differences.

Can 34CrNiMo6 Steel Be Nitrided?

Yes,As low alloy engineering steel,34CrNiMo6 can be nitrided.

During the nitriding process of 34CrNiMo6, Cr and Mo elements form stable nitrides when they come into contact with the nascent nitrogen atoms. Especially the Mo element can not only generate nitride elements, but also reduce the brittleness of the material at the nitriding temperature.

After nitriding treatment, 34CrNiMo6 steel can be used to produce important parts with special performance requirements, such as shafts, gears, and fasteners.

What is Hardness of 34CrNiMo6 Steel?

Under the softening annealing supply conditions, the hardness of 34CrNiMo6 steel is lower than 248HBW according to the standard, but the actual measured values are better than the standard, generally lower than 229HBW.

High hardness is not difficult to obtain for 34CrNiMo6 low alloy steel with good hardenability.34CrNiMo6 steel after quenching and tempering has good comprehensive properties, and the hardness is generally controlled between 28-34HRC.

If used for gears and shafts with higher hardness requirements, 34CrNiMo6 steel needs to be nitrided. The hardness after nitriding can reach 600-800HV3,with nitration hardness depth 0.1-06mm.

Is 34CrNiMo6 Steel Machinable?

The technicians still have a headache for the processing of 34CrNiMo6 steel.After annealing to soften the material, it is relatively easy to process it for further processing.

But the difficulty is the processing of 34CrNiMo6 after quenching and tempering.Due to the excellent hardenability of this material, the depth of the hardenable layer is wide,it is easy to cause tool wear during processing.In this case, the general suggestion is to reduce the processing speed and use a higher hardness tool for processing, such as CBN,PCBN tools.

34CrNiMo6 Steel Vs 30CrNiMo8 Steel

As heat-treatable low-alloy high-strength steels, 34CrNiMo6 and 30CrNiMo8 have common characteristics, and of course there are obvious differences for them.

- Chemical Composition

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo |

| 34CrNiMo6/1.6582 | 0.30-0.38 | ≤ 0.4 | 0.50-0.80 | ≤ 0.025 | ≤ 0.035 | 1.3-1.7 | 1.3-1.7 | 0.15-0.30 |

| 30CrNiMo8/1.6580 | 0.26-0.34 | ≤ 0.4 | 0.50-0.80 | ≤ 0.025 | ≤ 0.035 | 1.8-2.2 | 1.8-2.2 | 0.3-0.5 |

From the above table,we can almost regard 30CrNiMo8 as an upgraded version of 34CrNiMo6.There are obvious differences in C, Cr, Ni and Mo elements,and these elements will not only cause differences in manufacturing costs, but also affect their performance.

- Heat Treatment & Mechanical Property

| Heat Treatment Condition | ||

| Grade | Quenching Temperature,℃ | Tempering Temperature,℃ |

| 34CrNiMo6 | 830-860 | 540-680 |

| 30CrNiMo8 | 830-860 | 540-680 |

| Thickness of ruling section tR | ||||||||||||||||||

| Grade | tR≤160mm | 160< tR ≤330mm | 330< tR ≤660mm | |||||||||||||||

| Re Min Mpa | Rm Min Mpa | A min,% | KV min,J | Re Min Mpa | Rm Min Mpa | A min,% | KV min,J | Re Min Mpa | Rm Min Mpa | A min,% | KV min,J | |||||||

| l | tr | l | tr | l | tr | l | tr | l | tr | l | tr | |||||||

| 34CrNiMo6 | 600 | 800 | 13 | 9 | 45 | 22 | 540 | 750 | 14 | 10 | 45 | 22 | 490 | 700 | 15 | 11 | 40 | 20 |

| 30CrNiMo8 | 700 | 900 | 12 | 8 | 45 | 22 | 630 | 850 | 12 | 8 | 45 | 22 | 590 | 800 | 12 | 8 | 40 | 20 |

| Gas Nitriding | ||

| Grade | Surface Hardness HV3 | Nitration hardness depth |

| 34CrNiMo6 | 600-800 | 0.1-0.6mm |

| 30CrNiMo8 | 650-800 | 0.1-0.6mm |

HEAT TREATMENT FOR 34CRNIMO6 STEEL

Regardless of forged,rolled, round, square, shaft, plate, ring or other complex shapes, 34CrNiMo6 steel needs to be heat treated.Generally speaking, the conventional heat treatment is divided into Normalizing, Annealing, and Quenching & Tempering(QT).Next, we will introduce the heat treatment process widely used in 34CrNiMo6 steel: Annealing and QT.

How To Annealing 34CrNiMo6 Steel?

- Dehydrogenation Annealing

After 34CrNiMo6 steel is formed by hot processing, the first thing to consider is dehydrogenation annealing to reduce the internal hydrogen to avoid white spots and hydrogen embrittlement.

The annealing temperature is usually between 640-660℃,with sufficient holding time.The cooling rate should be slow enough to ensure that hydrogen can overflow and distribute evenly, and also can reduce the internal stress in the material.

- Complete Annealing

The complete annealing of 34CrNiMo6 steel refers to heating the temperature to Ac3+ (20~30℃), and then slowly cooling with the furnace after holding, in order to obtain a heat treatment method close to the equilibrium structure (pearlite structure), so it is also called recrystallization annealing.

This process can transform the original structure of the steel into a single uniform austenite, and then transform the austenite into ferrite and pearlite in slow cooling to achieve the purpose of refining the structure, reducing the hardness and eliminating internal stress.

Operating temperature:800-850℃,

Heating rate:heating up in stages,speed not exceeds 100℃/h

Hold time:The austenite homogenization time needs to be considered,20mm/h of the thickess for calculating holding time

Cooling rate:Slowly cool down with the furnace,speed not exceeds 50-100℃/h.

Hardess: below 248HBW.

How To Quenching And Tempering 34CrNiMo6 Steel?

If annealing is only a preliminary heat treatment for 34CrNiMo6, it can be said that quenching and tempering is the final heat treatment.After quenching and tempering, 34CrNiMo6 will obtain good comprehensive performance and can fully utilize its advantages in practical applications.

- 34CrNiMo6 Steel Quenching

The traditional method is oil quenching,and quenching temperature is controlled between 830-860℃.The advantage is that the cooling effect of the oil is mild, the internal stress generated is relatively small, and the material is not easy to crack.The disadvantage is precisely that the cooling is too slow to ensure a sufficient hardened layer. For products such as wind power shafts, the performance requirements cannot be met, especially for low-temperature impact.

If the water quenching method is used, although the thickness of the hardened layer can be guaranteed, the cooling rate is too fast, the temperature difference between the surface and the inside is too large, and the huge stress release will increase the tendency of the material to crack.Therefore, for the selection of quenching methods, comprehensive consideration is required to meet the material requirements.

- 34CrNiMo6 Steel Tempering

The tempering of 34CrNiMo6 steel should be carried out immediately after quenching.The choice of tempering temperature will make the hardness completely different. High temperature tempering makes the surface hardness low, low temperature tempering makes the surface hardness high.The tempering time should be sufficient, otherwise the hardness of the core of the material will be high, which will easily cause cracking

The use hardness of 34CrNiMo6 steel is generally 28-34HRC, so the corresponding tempering temperature is between 580-620℃.

How To Ensure Uniform Hardness of 34CrNiMo6 Steel After Quenched And Tempered?

First of all, the hardness of the material after quenching and tempering is uneven, which will make the stress of the material uneven after long-term load, and it is easy to cause fatigue cracks.In actual production, the uneven hardness of 34CrNiMo6 steel has been encountered many times. How to ensure the uniformity and stability of the hardness will be the topic we need to discuss next.

First of all,ensure that the composition of raw materials and the organizational structure are uniform. the material composition segregation and the uneven original structure will directly affect the uniformity of the surface hardness, making the material poor in hardenability, difficult to quench, and resulting in uneven hardness.

Secondly, ensure the quenching temperature and holding time.Low quenching heating temperature or short holding time, uneven furnace temperature distribution or large temperature difference in the furnace, will cause uneven heating of the material, uneven austenite composition, insufficient carbide dissolution, and ultimately lead to uneven surface hardness of the material.

The presence of oxide scale and decarburized layer on the surface of the material will also cause uneven hardness of the material.Therefore, our suggestion is to rough-turn the material first, and then perform quenching and tempering after removing the decarburized layer.Practice shows that the expected results are achieved.

WHAT IS GEAR?

We have seen many products using gears in our lives, but do you know what principle they use gears?According to its working principle, the gear has the following functions:

- Transmit mechanical power,such as automobile gear shifting device, industrial gearbox, etc

- Change the direction of movement, such as mechanical watches, head-shaking devices in electric fans, etc.

- Reduce speed and increase torque, such as motor reducer, various speed change mechanisms, etc

What Kind of Material is Suitable For Gears?

Gears rely on their own structural dimensions and material strength to withstand external loads, which requires materials to have high strength, toughness and wear resistance.Due to its complex shape and high precision, gears also need good material manufacturability.

The commonly used steels for making gears are quenched and tempered steel, quenched steel, carburized and quenched steel and nitrided steel.

Gears for the automotive industry

Automobile gears are mainly installed in the gearbox and differential. With it, the car can be driven.Due to the high transmission power, impact force,friction pressure, and poor working conditions,so automotive gears have relatively high requirements in terms of wear resistance, fatigue strength, core strength, and impact toughness.

Therefore, it is most suitable to use carburized steel after carburizing, quenching and low temperature tempering.

Representative steel grades:

German Grade: 20MnCr5,17CrNiMo6

Japanese Grade: SCM420, SCr420

American Grade: SAE8620,SAE8822

Gears for machine tool

Machine tool gears are mostly used in gearboxes to transmit power, change the speed and direction of movement.Compared with automobile gears, the load is not large, the speed is not high, and the working conditions are relatively good.

Therefore, machine tool gears require good comprehensive mechanical properties and are generally made of quenched and tempered steel.

The commonly used steel grades are:

WHERE CAN YOU BUY HIGH-QUALITY 34CRNIMO6 STEEL?

The high-quality 34CrNiMo6 steel is made, not tested. We believe that with us, we can meet all your needs for 34CRNIMO6 steel. If you are looking for this kind of material, please do not hesitate to contact us, we believe you will not be disappointed, we can help you.

What We Supply For 34CrNiMo6 Steel

| Supply Form | Size(mm) | Process | Tolerance | |

Round | Φ6-Φ100 | Cold Drawn | Bright/Black | Best H11 |

Φ16-Φ350 | Hot Rolled | Black | -0/+1mm | |

| Peeled/ground | Best H11 | |||

Φ90-Φ1000 | Hot Forged | Black | -0/+5mm | |

| Rough Turned | -0/+3mm | |||

Flat/Square/Block | Thickness :120-800 | Hot Forged | Black | -0/+8mm |

| Width:120-1500 | Rough Machined | -0/+3mm | ||

Heat Treatment:Normalized(+N),Annealed(+A),Quenched & Tempered(+QT)

What Size We stock For 34CrNiMo6 Steel

- Hot Rolled Round Bar:Φ16-Φ280mm,7 Days Delivery

- Hot Forged Round Bar:Φ140-Φ250mm,15 days Delivery

- Customized service:Special Size & Length,30 days Delivery

- Free Sample of 34CrNiMo6 Steel

Our Experiences,Our Advantages-Why Choose Us?

We have rich experience in handling orders for customers with professional process.

- Stable raw material control

- Laudable lead-time &shippment control

- Flexible payment terms

- Favorable orders follow-up management

- Traceable quality evaluation

- Remarkable after-sale service