C45 steel is an unalloyed medium carbon engineering steel which has 0.42%-0.5% Carbon.It offers moderate tensile strengths,wear resistance and good machinability.this material is capable of through hardening by quenching and tempering on limited sections,and also can be flame or induction hardened to surface hardness Min 55HRC.C45 is generally supplied in an untreated or normalised condition with a typical tensile strength range 570 – 700 Mpa and Brinell hardness range 170 – 210.

1.Supply Form & Size & Tolerance

Hot rolled bar:Φ6-Φ130mm,Length:3000-10000mm

Hot Forged round bar:Φ130-Φ1000mm,Length:3000-10000mm

Flat bar/Blcoks:Thickness :120-800mm xWidth:120-1500mm,Length:2000-6000mm

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |

2.Chemical Composition

| Grade | C | Mn | P | S | Si | Cr | Mo | Ni | Cr+Mo+Ni |

| C45/1.0503 | 0.42-0.50 | 0.50-0.80 | ≤ 0.045 | ≤ 0.045 | ≤ 0.4 | ≤ 0.4 | ≤ 0.1 | ≤ 0.4 | ≤ 0.63 |

| C45E/1.1191 | 0.42-0.50 | 0.50-0.80 | ≤ 0.03 | ≤ 0.035 | ≤ 0.4 | ≤ 0.4 | ≤ 0.1 | ≤ 0.4 | ≤ 0.63 |

| C45R/1.1201 | 0.42-0.50 | 0.50-0.80 | ≤ 0.03 | 0.02-0.04 | ≤ 0.4 | ≤ 0.4 | ≤ 0.1 | ≤ 0.4 | ≤ 0.63 |

3.Relevant Standards

| USA | UK | China | Japan | Australia |

| 1045 | 080M46 | 45# | S45C | 1045 |

4. Mechanical Property

| Mechanical properties a at room temperature in the quenched and tempered condition (+QT) | |||

| Diameter d mm | ≤ 16 | 16-40 | 40-100 |

| Thickness t mm | < 8 | 8-20 | 20-60 |

| Yield Strength Mpa | ≥490 | ≥430 | ≥370 |

| Tensile Strength Mpa | 700-850 | 650-800 | 630-780 |

| Elongation, % | ≥14 | ≥16 | ≥17 |

| Reduction of area ,% | ≥35 | ≥40 | ≥45 |

| impact,J | ≥25 | ≥25 | |

| Mechanical properties a at room temperature in the normalized condition (+N) | |||

| Diameter d mm | ≤ 16 | 16-100 | 100-250 |

| Thickness t mm | ≤ 16 | 16-100 | 100-160 |

| Yield Strength Mpa | ≥340 | ≥305 | ≥275 |

| Tensile Strength Mpa | ≥620 | ≥580 | ≥560 |

| Elongation, % | ≥14 | ≥16 | ≥16 |

5.Forging

C45 steel forging temperature:900 – 1100°C ,cooling as slowly as possible in still air or in sand after forged.

6.Heat Treatment

- Normalizing: 840 – 900°C,Cooling in air

- Soft Annealing:680 – 710°C,Cooling in furnace

- Stress relieve:550-650°C,Cooling in air

- Oil Quenching:840 – 870°C

- Water Quenching:820 – 850°C

- Tempering:540 – 680°C,Cooling in air

- Induction or Flame hardening:870-900°C

7.Surface Hardness

- Natural (untreated) (+U):172-242HB

- Treated to improve shearability (+S):Max 255HB

- Soft annealed (+A):Max 207HB

- Flame or induction hardening:Min 55HRC

| NORMAL HARDENABILITY +H (850°C - hardness HRC – distance mm) | |||||||||||||

| HRC - mm | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 13 | 15 |

| MAX | 62 | 61 | 61 | 60 | 57 | 51 | 44 | 37 | 34 | 33 | 32 | 31 | 30 |

| MIN | 55 | 51 | 37 | 30 | 28 | 27 | 26 | 25 | 24 | 23 | 22 | 21 | 20 |

8.Application

C45 is widely used in many industries which require more strength,hardness and wear resistance.Typical applications include tools, shafts, nuts, bolts, connecting rods, screws, rollers,axles, spindles, studs, knives and many automotive and general engineering components

C45 STEEL BUYING GUIDE

As the most common medium carbon steel C45 steel in Europe, its role in the market is similar to that of the American grade AISI 1045 steel.Due to the ubiquity of C45 steel in the market, it is not difficult to find it, but it is not so easy to find high-quality C45 steel. This is indeed the case.

Through our guidance, we can help you build a knowledge system of high-quality C45 steel,and help you choose and buy the right material for you need.

So let’s get to work.

WHAT IS C45 STEEL?

European steel grades often have two expressions, which come from two standard systems. One is the designation method of DIN17006 standard system, which uses numbers, element symbols and codes to express. The other is the DIN17007 standard digital material number system, which completely uses numbers to indicate the elements, content, requirements, and status of the grade.Here we mainly introduce the first method-DIN17006.

The DIN17006 standard stipulates that a steel grade is composed of three parts. The main body is expressed by the tensile strength or chemical composition of the steel; in front of the main body are the abbreviations indicating the smelting method or original characteristics of the steel. In practice, the non-subject parts are generally omitted.

For carbon steel, there are usually two methods. One is that the steel grade body consists of the letters “St” (abbreviation for Stahl) and the lower limit value of tensile strength. For example, St52 means carbon steel with a tensile strength of not less than 520Mpa.

The other is that the main steel grade is composed of the chemical symbol of carbon C” followed by the carbon content value. Take C45 for example, C represents carbon steel, and 45 represents 0.45% carbon content. It’s that simple and clear.

For DIN 17007, the rules here are relatively complicated,and we will introduce it in detail in the future “How to” series.Here, we just need to know for C45,1.0503 is its corresponding digital code in the DIN 17007 system.

SPECIAL SYMBOLS FOR C45 STEEL

C45: P≤0.045,S≤0.045

C45N: C45 with Normalized condition

C45E: P S element content controlled with P≤0.03,S≤0.035

C45R: P S element content controlled with P≤0.03,S:0.02-0.04

Ck45: P S element content controlled with P≤0.035,S≤0.03

Cm45: P S element content controlled with P≤0.03,S:0.02-0.035

Cf45: C45 with Quenched condition

Cq45: Cold heading Steel

IS C45 STEEL SAME AS S45C STEEL?

Although their carbon content is around 0.45%, they are still equivalent grades.C45,also refers to DIN 1.0503, is the grade of European standard EN10083,while S45C,comes from the JIS G4051 Japanese standard.

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo |

| C45/1.0503 | 0.42-0.50 | ≤0.4 | 0.5-0.8 | ≤0.045 | ≤0.045 | ≤0.4 | ≤0.4 | ≤0.1 |

| S45C | 0.42-0.48 | 0.15-0.35 | 0.6-0.9 | ≤0.03 | ≤0.035 | ≤0.2 | ≤0.2 | / |

From the above table,we can see that the contents of the main elements are extremely close.However, as harmful elements and residual elements, the Japanese standard S45C is obviously stricter than the C45 control.So we must be very careful when considering alternatives

International Equivalent Grade

China/GB 699:45#

USA/ASTM A29:AISI 1045

UK/BS 970:EN8/080M40

QUICK FAQS FOR C45 STEEL

Is C45 Steel High-Carbon Steel?

From the above content,we can clearly see that C45 steel has carbon content with range 0.42-0.50%.Compared with the carbon content of high-carbon steel in the carbon steel classification, it is obviously not up to the level of high-carbon steel(C>0.6%).

Does C45 Steel Contain Alloying Elements?

From the chemical composition table of C45 steel, we can see that the main composition is free of alloying elements.But in fact, C45 contains alloying elements, that is, it contains a certain amount of residual alloying elements.When smelting C45 steel, we must strictly limit the content of such alloying elements.

Can C45 Steel Be Welded?

As we all know, low-carbon steel has good welding performance, such as AISI 1020 steel, S355J2 steel, but as a medium-carbon C45 steel, its welding performance gradually deteriorates.If the C45 steel is welded randomly according to the welding process of low carbon steel, the weldment will often crack and cause the product to be scrapped.

C45 steel is a medium carbon steel and is often used to manufacture mechanical parts. Therefore, when welding C45 steel, if the selection of welding materials and the control of the welding process are not strict, the weld and the welding heat-affected zone(HAZ) may produce hard and brittle martensite organization, leading to the deterioration of the performance of the joint, which is easy to damage under vibration or fatigue load.

The welding of C45 steel requires strict welding process to control each procedure, especially preheating before welding and timely heat treatment after welding to prevent welding cracks and ensure the safety and reliability of weldments.

Is C45 Steel Suitable For Shafts?

When selecting materials to make shaft workpieces, different heat treatment methods (such as quenching and tempering, normalizing, quenching, etc.) should be adopted according to the working conditions and requirements of their use to obtain certain strength, toughness and wear resistance.

C45 Steel Application:Shaft

C45 steel is a commonly used material for shaft workpieces. As a high-strength medium-carbon steel, it is not only cheap, but also can obtain comprehensive mechanical properties such as higher strength and toughness,better cutting performance after quenching and tempering (or normalizing).

C45 Steel Vs C60 Steel

We can see that many standards include C45 and C60 steel, such as EN10083, EN10250, etc., which are indeed widely used.Next, we will briefly talk about their differences.

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo |

| C45/1.0503 | 0.42-0.50 | ≤0.4 | 0.5-0.8 | ≤0.045 | ≤0.045 | ≤0.4 | ≤0.4 | ≤0.1 |

| C60/1.0601 | 0.57-0.65 | ≤0.4 | 0.6-0.9 | ≤0.045 | ≤0.045 | ≤0.4 | ≤0.4 | ≤0.1 |

From the above chemical composition comparison, it can be seen that C45 belongs to medium carbon steel, while C60 can be classified into the ranks of high carbon steel.Therefore, compared with C45 steel, C60 steel has a higher carbon content, which means that C60 has higher strength, wear resistance and hardenability, but its weldability and toughness are often poor.

C45 steel has good comprehensive properties which has good strength, plasticity and toughness,and it is often used to make shafts, gears and other parts.While C60 steel,according to its characteristics,it is used to manufacture spring coils, various washers, cams, steel ropes, etc., which are subjected to large forces, work under friction conditions, and require high strength, wear resistance and certain elasticity.

C45 STEEL INDUCTION HARDENING

Compared with traditional C45 steel quenching and tempering heat treatment, C45 steel induction hardening has become more and more popular due to its advantages of fast heating speed, energy saving, high production efficiency, environmental protection, and automatic operation.

The principles of intermediate frequency and high frequency induction hardening of C45 steel are the same. They are all heat treatment processes that use electromagnetic induction, skin effect, eddy current and resistance heat to rapidly heat and cool the surface of the workpiece.

The selection of induction heating frequency is based on the requirements of heat treatment and heating depth. The higher the frequency, the shallower the heating depth.

- C45 STEEL Medium Frequency Induction Hardening

For C45 steel medium frequency induction hardening, its application frequency is usually 2000-8000HZ, the hardened layer after quenching is deep, generally 3-5mm.The surface layer can be hardened in a short time with fine crystal structure and small structural deformation.

C45 Steel Medium Frequency Induction Hardening

After medium frequency induction hardening,C45 steel is suitable for parts subject to twisting and pressure loads, such as crankshafts, large gears, grinding machine spindles, etc.

- C45 STEEL High Frequency Induction Hardening

For C45 steel high frequency induction hardening,its operating frequency is usually above 10KHZ,and the hardened layer after quenching is shallow, generally 1.5~2mm, but its hardness is high,and it is not easy to be oxidized.

After high-frequency induction heating and quenching, C45 steel has small deformation and high quenching quality, and its surface properties are significantly improved. The surface is quenched martensite, while the core is still normalized,which makes the material both wear-resistant and strong toughness.

After high frequency induction hardening,C45 steel is suitable for parts that work under friction conditions, such as generally smaller gears, shafts.

C45 Shaft for High Frequency Induction Hardening

HOW TO MANUFACTURE HIGH QUALITY C45 STEEL?

Strictly speaking, as the most common medium carbon steel, C45 steel has a wide range of applications, but the resulting quality differences are difficult to solve. Therefore, we are faced with the question of how to manufacture high-quality C45 steel, then we will have a good discussion on this topic.

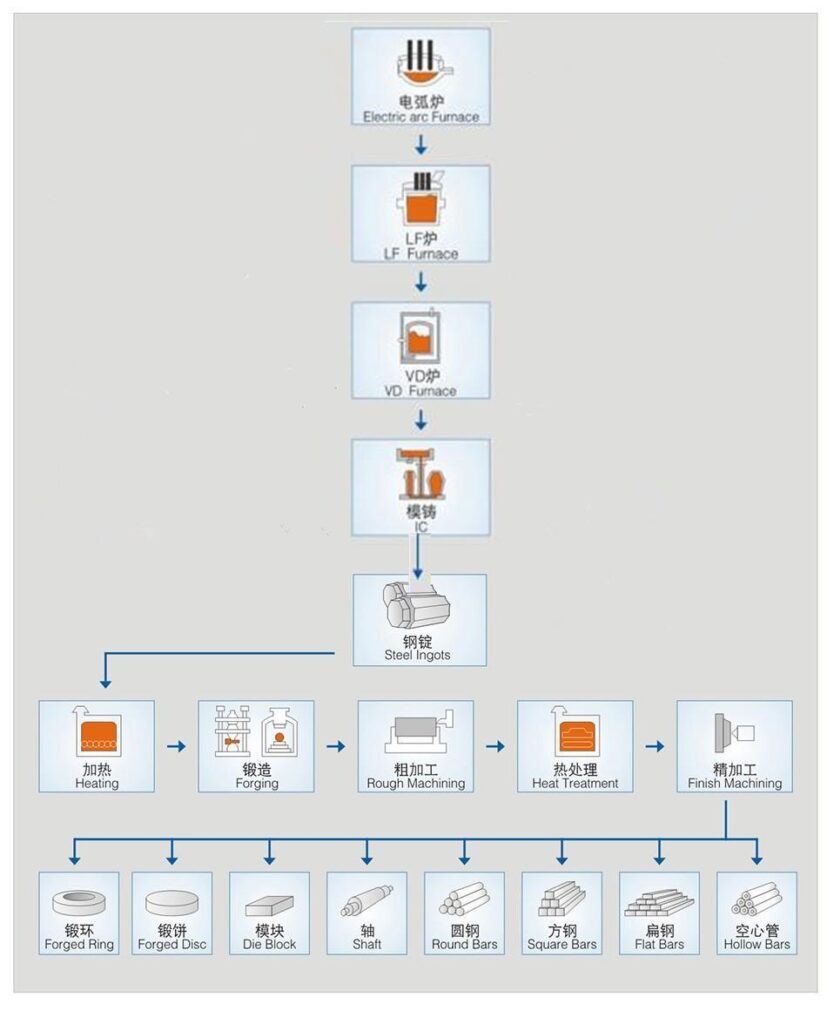

From the figure above, we can roughly see a production flow chart of C45 steel,we will talk about a few important control points in the flow chart.

- C45 Steel Melting Route

The current mainstream method of smelting C45 steel is mainly Electric Arc Furnace smelting process and converter steelmaking process.

For C45 steel melting,the raw material used in converter steelmaking is molten iron, while the electric arc furnace uses scrap steel, which determines that the molten iron in converter steelmaking has high purity, few residual alloying elements.

In addition, converter steelmaking can control harmful elements well, such as P and S elements can be controlled at very low levels (<0.01%),also the gas content of the converter molten steel is low, O≤20ppm, N≤50ppm,H≤2ppm.

Having said that, it needs to be clarified that this is not to say that electric arc furnaces are not suitable for the smelting of C45 steel. For the electric arc furnace, scrap steel can be recycled and reused, melting process is flexible, and suitable for the smelting of small batches/multiple varieties of special steel, which all indicate that it has broad prospects and development trends.

- C45 Steel Hot Forging/Rolling

For the hot working of C45 steel, the control of the working temperature and the control of the rolling and forging ratios are particularly important.

For C45 steel, too high processing temperature will lead to coarse grains of the material, and even significantly reduce the mechanical properties of the material. Too low temperature will cause the material to work harden and crack during processing, resulting in scrap.

A suitable rolling-forging ratio can not only improve the as-cast defects of the material, such as porosity, pores, etc., but also improve the mechanical properties of the material.For C45 steel,we generally require the forging ratio to be greater than 4 and the rolling ratio to be above 9.

- C45 Steel Heat Treatment

In order to make high-quality C45 steel, the role of heat treatment is essential.For the heat treatment of C45 steel, the common heat treatment is generally annealing, normalizing and quenching and tempering.For them, how to correctly balance the heating temperature, holding time and cooling speed has become the key.

For the annealing of C45 steel, generally after casting, forging, and welding, C45 steel needs to be annealed to improve the homogenization of chemical composition, remove residual stress, or obtain expected physical properties.The microstructure of C45 steel after annealing is ferrite and pearlite.

For the normalizing of C45 steel, as a preliminary heat treatment, it can refine the grain and improve the structure, and usually prepares the structure for further heat treatment of the material, such as quenching and tempering. Sometimes it can also be used as a final heat treatment for lightly loaded parts with little stress.The microstructure of C45 steel after normalizing is ferrite and pearlite.

For the quenching and tempering of C45 steel, the hardness after quenching is about 60HRC with structure martensite.After tempering, C45 steel usually corresponds to the following microstructures

- Tempered martensite -Low temperature tempering

- Tempered troostite -Medium temperature tempering

- Tempered sorbite -High temperature tempering

C45 steel has good comprehensive mechanical properties after quenching and tempering treatment, and is widely used in various important structural parts, especially those connecting rods, bolts, gears and shafts that work under alternating loads.

BUYING C45 STEEL: WHICH MANUFACTURER SHOULD YOU WORK WITH?

As the most common steel grade in the market, it often tests the manufacturing level of suppliers.As a C45 forge manufacturer with over 10 years of manufacturing experience, no one is more familiar with it than us. We are confident to provide high-quality materials and supporting craftsmanship.

What We Supply For C45 Steel

- Hot Rolled Round Bar:Φ20-Φ350mm,7 Days Delivery

- Hot Forged Round Bar:Φ140-Φ250mm,15 days Delivery

- Customized service:Special Size & Length,30 days Delivery

- Free Sample of C45 Steel

Heat Treatment

- Normalized(+N)

- Annealed(+A)

- Quenched & Tempered(+QT)

Machining

Turning/Milling/Drilling/Peeling/Polishing