AISI 4130 steel Manufacturer and Exporter,supplied with round,square,flat,block,and shaft etc.AISI 4130 steel is defined as a low alloy steel which contains 1%Cr and 0.2%Mo as strengthening alloy elements.it offers good strength,toughness, corrosion resistance and machinability.Compared with AISI 4140,It has lower carbon,0.28-0.33%,so it can be welded easily. AISI 4130 is commonly supplied in the hardened and tempered condition with a hardness range 207-235HB.

1.Supply Form & Size & Tolerance

| Supply Form | Size(mm) | Process | Tolerance | |

Round | Φ6-Φ100 | Cold Drawn | Bright/Black | Best H11 |

Φ16-Φ350 | Hot Rolled | Black | -0/+1mm | |

| Peeled/ground | Best H11 | |||

Φ90-Φ1000 | Hot Forged | Black | -0/+5mm | |

| Rough Turned | -0/+3mm | |||

Flat/Square/Block | Thickness :120-800 | Hot Forged | Black | -0/+8mm |

| Width:120-1500 | Rough Machined | -0/+3mm | ||

Remark:Tolerance can be customized as per requests

2.Chemical Composition

| Standard | Grade | C | Si | Mn | P | S | Cr | Mo |

| EN10083 | 25CrMo4 | 0.22-0.29 | ≤0.4 | 0.6-0.9 | ≤0.025 | ≤0.035 | 0.9-1.2 | 0.15-0.3 |

| 1.7218 | ||||||||

| ASTM A29 | 4130 | 0.28-0.33 | 0.15-0.35 | 0.4-0.6 | ≤0.035 | ≤0.04 | 0.8-1.1 | 0.15-0.25 |

| JIS G4105 | SCM430 | 0.28-0.33 | 0.15-0.35 | 0.6-0.85 | ≤0.035 | ≤0.04 | 0.9-1.2 | 0.15-0.3 |

| GB 3077 | 30CrMo | 0.26-0.33 | 0.17-0.37 | 0.4-0.7 | ≤0.03 | ≤0.03 | 0.8-1.1 | 0.15-0.25 |

3.Physical Property

| Density g/cm3 | 7.85 |

| Melting point °C | 1432 |

| Poisson's ratio | 0.27-0.30 |

| Machinability (AISI 1212 as 100% machinability) | 70% |

| Specific Gravity | 7.8 |

| Thermal conductivity W/(m.K) | 46 |

| Modulus of Elasticity Tension | 29 |

4. Mechanical Property

| Tensile Strength Mpa | Yield Strength Mpa | Elongation % | Hardness HBW | Impact Charpy-V, -18ºC,J | |

| 60K | ≥ 586 | ≥ 414 | ≥ 18 | 174-237 | ≥ 42 |

| 75K | ≥ 655 | ≥ 517 | ≥ 17 | 197-235 | ≥ 42 |

5.Forging

Forging temperature of AISI 4130 steel should be carried out between 950℃-1200℃,The lower the forging-ending temperature ,the finer the grain size .Hold suitable time for the steel to be uinformly heated before forge, but don’t forge below 950℃.AISI 4130 steel should be cooled as slowly as possible after forged.

6Normalizing

Normalizing is used to refine the structure of forgings that might have cooled non-uniformly after forged,and considered as a conditioning treatment before final heat treatment.Normalizing temperature for AISI 4130 steel should be carried out between 880℃-900℃. hold suitable time for the steel to be uniformly heated to complete the ferrite to austenite transformation.Cool in still air.

7.Annealing

AISI 4130 steel can be annealed to relieve stress after forging ,and obtain a good structure suitable for machining,Annealing temperature should be carried out between 800℃-850℃, hold suitable time for the steel to be heated uniformly. Cool slowly in the furnace.

8.Hardening

This heat treatment will obtain martensite structure after quenched,it will increase the surface hardness and strength.AISI 4130 steel should be carried out between 870℃-890℃, hold suitable time for the steel to be thoroughly heated, then quench in oil, or water.Tempering should be followed immediately after quenched.

9.Tempering

Tempering is usually carried out to relieve stresses from the hardening process, and will optimize hardness and mechanical properties. The actual tempering temperature will be chosen to meet the required properties.Heat the AISI 4130 carefully to a suitable temperature ,usually between 400℃-570℃, soak at the temperature for 2 hours per 25mm of ruling section, then cool in air.The lower the tempering temperature the greater the strength. However, Tempering between 250-375°C is not advised as tempering within this range will seriously reduce the impact value.

10.Application

AISI 4130 steel finds many applications as forgings for the aerospace,oil and gas,automotive, agricultural and defense industries etc.

Typical applications for 4130 steel uses include:forged valve bodies, pumps,Aircraft engine mounts,Welded tubing,fittings,Hydraulic tools,etc

AISI 4130 STEEL BUYING GUIDE

As we all know, AISI 4130 steel is widely used in many fields, such as aerospace, automobile, agriculture and defense industry, especially in the oil and gas industry which can be seen everywhere.We will try to unveil the popular veil of AISI 4130 steel application in the industry, so as to further understand its characteristics.

Through this guide, we believe that you not only have the ability to identify high-quality AISI 4130 steel, but also you can find the best way to purchase the best quality of 4130 steel in the market!

WHAT DOES AISI 4130 MEAN?

We explained the meaning of many American grades in the “How to” series on the FAQ&BLOG page, such as similar AISI 4140 steel and AISI 4340 steel, so please come and try to analyze the meaning contained in AISI 4130 steel.

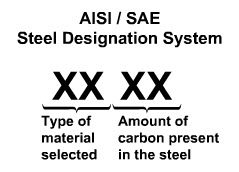

The first two digits in the steel number generally indicate the type of steel,while the last two digits indicate the amount of carbon present in the steel.We can see the below structure diagram From AISI/SAE Steel Designation System,and we can find UNS G41300, it is the number for 4130 steel.

From the above, we can clearly know that the last two “30” in 4130 represent an average carbon content of 0.30%.For the specific meaning of the first two digits in AISI 4130 steel, we can see the following table.

Molybdenum Steel | 40XX | Mo 0.20-0.25% |

| 44XX | Mo 0.40-0.52% |

|

| Chromium-Molybdenum Steel | 41XX | Cr 0.50-0.95%, Mo 0.12-0.30% |

Nickel-Chromium-Molybdenum Steel | 43XX | Ni 1.82%, Cr 0.50-0.80%, Mo 0.25% |

| 47XX | Ni 1.05%, Cr 0.45%, Mo 0.20-0.35% | |

Nickel-Molybdenum Steel | 46XX | Ni 0.85-1.82%, Mo 0.20-0.25% |

| 48XX | Ni 3.50%, Mo 0.25% |

IS AISI 4130 SAME AS 30CRMO?

First of all, if we want to clarify this question, let’s take a look at their respective origins.AISI 4130 is a grade from ASTM A29 American standard, while 30CrMo comes from Chinese GB 3077 standard. They can be said to be similar grades. Let’s take a look at their specific composition differences, please see the table below.

| Standard | Grade | C | Si | Mn | P | S | Cr | Mo |

| ASTM A29 | 4130 | 0.28-0.33 | 0.15-0.35 | 0.4-0.6 | ≤0.035 | ≤0.04 | 0.8-1.1 | 0.15-0.25 |

| GB 3077 | 30CrMo | 0.26-0.33 | 0.17-0.37 | 0.4-0.7 | ≤0.03 | ≤0.03 | 0.8-1.1 | 0.15-0.25 |

From the above table,we can intuitively see their small differences, which are so small that they can be ignored.In actual use, we can completely replace each other, of course, the premise is to carefully check whether their chemical composition is in the overlapping range.

Other Equivalent Grade

Europe/EN10083 &EN10250:25CrMo4/DIN 1.7218

Japan/JIS G4105:SCM430

UK/BS970:708A25/708M25

QUICK FAQS FOR AISI 4130 STEEL

Is AISI 4130 Steel Low-Carbon Low-Alloy Steel?

From the above content,we can clearly see that AISI 4130 has carbon content with range 0.28-0.33%.According to the classification of carbon content, it belongs to the Medium-carbon series( 0.25%≤ C<0.6%).With Alloy elements below 5%,we can define AISI 4130 as low alloy steel.

Can AISI 4130 Steel be Cold Drawn?

Yes,AISI 4130 steel can be cold drawn with high-precision size and smooth surface.After cold drawn process,AISI 4130 steel has good mechanical properties and can be directly applied without further processing.

In addition to cold-drawn round steel, AISI 4130 can also be processed into other shapes, such as square steel, flat steel, hexagonal steel, and even special-shaped steel.

Can AISI 4130 Steel be Nitrided?

Yes,as the 4130 steel in the AISI 41XX series of medium-carbon low-alloy steels, it contains Cr and Mo elements, which can form stable nitrides by nitrogen atoms and improve the nitriding effect.

After nitriding, AISI 4130 steel has significantly improved wear resistance, surface hardness, fatigue limit and corrosion resistance.

How Hard is AISI 4130 Steel?

AISI 4130, as a steel for petroleum and petrochemicals, is usually used after quenching and tempering, with high strength and toughness. According to the requirements of API 6A, the hardness is generally between 197-237HBW, which is the requirement of AISI 4130 75K.

The application of higher hardness of AISI 4130 steel can be achieved by nitriding,it can get surface hardness 550-700HV3,with nitration hardness depth 0.2-0.7mm.

AISI 4130 Steel vs AISI 4135 Steel

As a Cr-Mo series alloy structural steel,AISI 4130 and AISI 4135 belong to the ASTM A29 standard.First of all, let’s take a look at their specific composition differences.

| Grade | C | Si | Mn | P | S | Cr | Mo |

| 4130 | 0.28-0.33 | 0.15-0.35 | 0.4-0.6 | ≤0.035 | ≤0.04 | 0.8-1.1 | 0.15-0.25 |

| 4135 | 0.33-0.38 | 0.15-0.35 | 0.7-0.9 | ≤0.035 | ≤0.04 | 0.8-1.1 | 0.15-0.25 |

From the above table,the carbon content of AISI 4135 is higher than 4130, so the hardness, tensile strength and yield strength of AISI 4135 are relatively better for the two materials after heat treatment. However, AISI 4130 is better in terms of toughness.

According to the classification of API temperature grade, 4135 and 4130 steel are often applied to P-U grade, which is -29℃—+121℃. However, due to the slightly lower carbon content of 4130 steel, its low temperature performance is slightly better than that of 4135 steel.(the difference is also relatively speaking, basically the difference is not very large).

AISI 4130 STEEL VS AISI 4140 STEEL

We analyze AISI 4130 and AISI 4140 from the naming rules of American steel grades.The most sure thing is that they belong to Chromium-Molybdenum Steel.Then let’s take a concrete look at their performance differences in various aspects.

- Chemical Composition

| Grade | C | Si | Mn | P | S | Cr | Mo |

| 4130 | 0.28-0.33 | 0.15-0.35 | 0.4-0.6 | ≤0.035 | ≤0.04 | 0.8-1.1 | 0.15-0.25 |

| 4140 | 0.38-0.43 | 0.15-0.35 | 0.75-1.0 | ≤0.035 | ≤0.04 | 0.8-1.1 | 0.15-0.25 |

From the above table,we can clearly see that, as Cr-Mo series alloy steels, AISI 4130 and AISI 4140 have the same content of Cr and Mo elements, but the difference is obvious in C and Mn elements.

- Heat Treatment

| 4130 | 4140 | |

| Normalizing,℃ | 870-900 | 850-900 |

| Annealing,℃ | 830-850 | 850 |

| Quenching,℃ | 860-890 | 840-880 |

| Tempering,℃ | 540-570 | 220-650 |

| Quenching Medium | Oil/Water | Oil/Water |

| Hardness,HRC | 32-38 | 28-58 |

AISI 4140 forged flat steel with QT condition

- Mechanical Property

Normalizing Mechanical Property Comparison

| Grade | Tensile Strength | Yield Strength | Elongation | Reduction of Area | Impact Charpy-V | Hardness |

| 4130 | 670Mpa | 435Mpa | 25.5% | 60% | 86 | 197HBW |

| 4140 | 1020Mpa | 655Mpa | 17.7% | 47% | 23 | 302HBW |

Annealing Mechanical Property Comparison

| Grade | Tensile Strength | Yield Strength | Elongation | Reduction of Area | Impact Charpy-V | Hardness |

| 4130 | 560Mpa | 360Mpa | 28.2% | 56% | 62 | 156HBW |

| 4140 | 655Mpa | 415Mpa | 25.7% | 57% | 55 | 197HBW |

Quenching&Tempering Mechanical Property Comparison

| Grade | Tensile Strength | Yield Strength | Elongation | Reduction of Area | Impact Charpy-V |

| 4130 | ≥950Mpa | ≥800Mpa | ≥12% | ≥45% | ≥80 |

| 4140 | ≥1100Mpa | ≥950Mpa | ≥12% | ≥45% | ≥80 |

- Weldability

According to the carbon equivalent formula,CE=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15.

| Carbon equivalent (CE) | Weldability |

| ≤0.35 | Excellent |

| 0.36–0.40 | Very good |

| 0.41–0.45 | Good |

| 0.46–0.50 | Fair |

| ≥0.5 | Poor |

we probably calculated that the CE of AISI 4140 is around 0.8, while AISI 4130 has a CE of around 0.6.From the above table,we can know that the weldability of both materials is poor.But in comparison, AISI 4130 is relatively easy to weld due to its low carbon content.

The preheating process before welding is very necessary for both, especially AISI 4140 steel with high carbon content, which can effectively prevent welding cracks.The implementation of post-weld heat treatment(PWHT) is also very necessary for the two materials,which can effectively release the welding stress and prevent the appearance of cracks.

- Hardenability

The hardenability is mainly affected by the chemical composition, and the most influential element is carbon. When the C% is less than 1.2%, as the carbon concentration in austenite increases, the critical cooling rate is significantly reduced, and the hardenability of the steel is increased.

The second is alloying elements. Except for cobalt, most of the alloying elements dissolve into austenite to reduce the critical cooling rate, thereby improving the hardenability of steel.

From the above chemical composition comparison, it can be seen that the carbon content of AISI 4140 is significantly higher than that of AISI 4130.In addition, the Mn content of AISI 4140 is also higher than that of AISI 4130, and the Mn element plays a certain role in improving the hardenability.Through comprehensive comparison, the hardenability of AISI 4140 is relatively higher.

HOW TO ACHIEVE API 6A 75K FOR AISI 4130 STEEL?

As a petroleum and petrochemical steel, AISI4130 material is widely used in the field of petroleum and natural gas.We must strictly implement the standards of this industry, of which API 6A is the most widely used.Next, we will discuss the specific requirements of AISI 4130 steel 75K in the API 6A standard.

AISI 4130 75K Requirement

| Material Designation | 0.2% Offset yield strength Min,Mpa(psi) | Tensile strength Min,Mpa(psi) | Elongation in 50 mm (2 in) Min,% | Reduction in Area Min,% | Impact(-60℃) Min,J | Hardness HBW |

| 75K | 517(75,000) | 655(95,000) | 17 | 35 | 27 | 197-237 |

The above is the specific requirements of AISI 75K material in API 6A, so how to achieve it, we have to start with composition and process control, and implement it step by step.

- Melting Method

Steelmaking can be carried out through an electric furnace process with continuous xenon oxygen removal (AOD) or vacuum treatment (EFVD), as well as vacuum induction remelting (VIM), vacuum arc remelting (VAR), or electric furnace slag remelting (ESR) shall also be acceptable.

- Chemical Composition

It is obviously not enough to require the chemical composition of AISI 4130 in accordance with the ASTM A29 standard. We need to adjust the lower limit of its alloy composition and effectively control harmful elements according to the following table.

| C | Si | Mn | P | S | Cr | Mo | |

| ASTM A29 | 0.28-0.33 | 0.15-0.35 | 0.4-0.6 | ≤0.035 | ≤0.04 | 0.8-1.1 | 0.15-0.25 |

| Adjustment for API 6A | 0.28-0.33 | 0.15-0.35 | 0.4-0.6 | ≤0.025 | ≤0.025 | 1.0-1.1 | 0.2-0.25 |

We must at least increase the alloying elements above the midline, and control the P/S harmful elements below 0.025% or even lower according to the PSL 3 level (PSL 4: P≤0.015%, S≤0.01%)

- Hot Forging

Forging can apply pressure to AISI 4130 material to produce plastic deformation to obtain certain mechanical properties. Through a suitable forging process, it can eliminate defects such as as-cast looseness of the material during the smelting process, optimize the microstructure and improve performance.

According to API requirements, we need to ensure that AISI 4130 has a suitable forging ratio, at least 4:1 or greater.

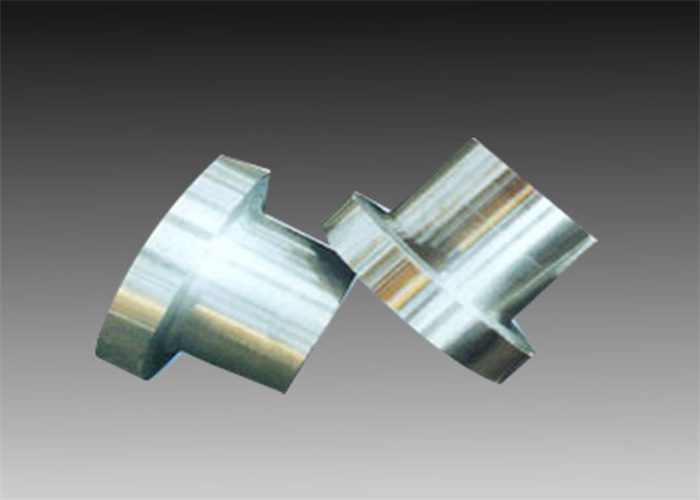

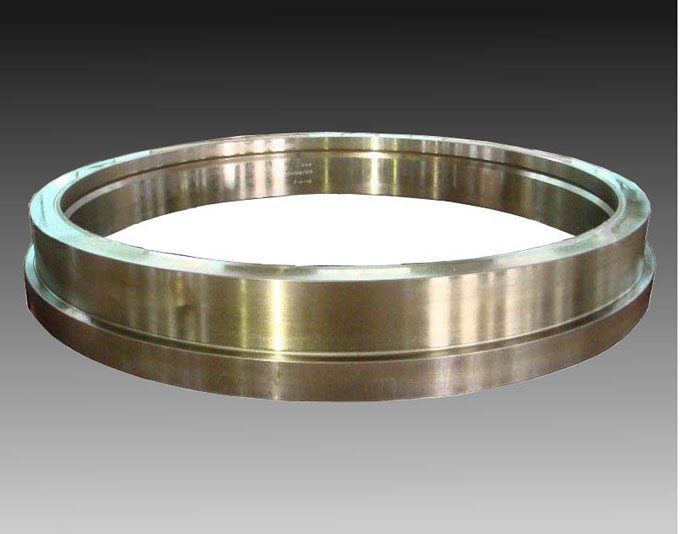

Forging AISI 4130 steel shaft

- Heat Treatment

As the last process, heat treatment is very important for 4130 materials to meet the requirements of 75K. According to the requirements of API 6A, AISI 4130 steel should be normalized(N), quenched(Q) and tempered(T), that is, N+Q&T.The specific requirements are shown in the table below

| PROCESS | TEMPERATURE RANGE | TIME AT TEMPERATURE | COOLING |

| Normalizing | 870-900℃ | 0.5hr/inch of metal thickness | Air cool to room temperature |

| Quenching | 870-890℃ | 0.5hr/inch of metal thickness | Water or Oil/Polymer |

| Tempering | 650-700℃ | 0.5hr/inch of metal thickness | Air cool to room temperature |

Note 1:The austenitizing temperature shall be less than the normalizing temperature.

Note 2:Water is the preferred quenching medium for all 4130 steel parts,however,oil or polymer may be used for parts whose section thickness is 6″or smaller.

Note 3:Cooling media temperature shall not exceed 38℃ at the start of the quench, and for bath type quenching the temperature of the bath at the end of the quench shall not exceed 49℃.

BUYING AISI 4130 STEEL: WHICH MANUFACTURER SHOULD YOU TRUST?

It is not difficult to find AISI 4130 steel in the market, but manufacturers who have API certification and can make high-quality AISI 4130 steel are hard to find. Fortunately, we can provide what you want.

Here, you can not only find any shape you want, but also you don’t have to worry about the quality of AISI 4130. We are proud that the quality from us can withstand the inspection of many customers.

AISI 4130 Steel Forged products

What We Supply For AISI 4130 Steel

- Hot Rolled Round Bar:Φ20-Φ350mm,7 Days Delivery

- Hot Forged Round Bar:Φ140-Φ250mm,15 days Delivery

- Customized service:Special Size & Length,30 days Delivery

- Free Sample of AISI 4130 Steel

In addition to providing AISI 4130 steel,we also have a large inventory of high-quality AISI 4140 steel, 34CrNiMo6 steel, 30CrNiMo8 steel, AISI 4340 steel, and AISI 8620 steel.We will never fail in providing the best and the highest quality special steel for you!