30CrNiMo8|DIN 1.6580 is a heat treatable steel which has at least 1.8%Cr,1.8%Ni,and 0.3%M0 as strengthening alloy elements.It is usually supplied with quenched and tempered condition with a typical tensile strength of 1100 -1300 N/mm². 30CrNiMo8 steel is used for automotive and general components which requires high demands on strength and toughness and good hardenability.It is especially suitable for heavy duty parts in the aviation, automotive and military industries.

1.Supply Form & Size & Tolerance

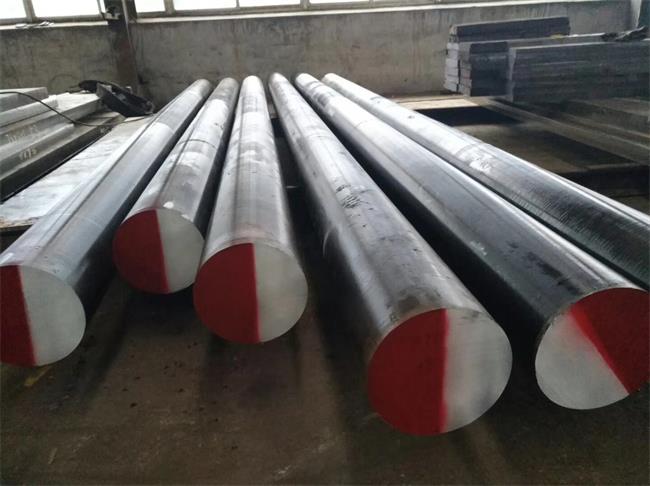

Hot rolled bar:Φ6-Φ130mm,Length:3000-10000mm

Hot Forged round bar:Φ130-Φ1000mm,Length:3000-10000mm

Flat bar/Blcoks:Thickness :120-800mm xWidth:120-1500mm,Length:2000-6000mm

| Surface Finish | Tolerance |

| Black For Forged condition | (0,+5mm) |

| Black For Rolled condition | (0,+1mm) |

| Rough Turned | (0,+3mm) |

| Grinding | Best h9 |

| Polished | Best h11 |

| Peeled | Best H11 |

| Cold Drawn | Best H11 |

2.Chemical Composition

| Standard | Grade | C | Si | Mn | P | S | Cr | Ni | Mo |

| EN10083 | 30CrNiMo8/1.6580 | 0.26-0.34 | ≤0.4 | 0.5-0.8 | ≤0.025 | ≤0.035 | 1.8-2.2 | 1.8-2.2 | 0.3-0.5 |

| EN10250 | 0.26-0.34 | ≤0.4 | 0.3-0.6 | ≤0.035 | ≤0.035 | 1.8-2.2 | 1.8-2.2 | 0.3-0.5 |

3.Relevant Standards

| USA | UK | France | Italy |

| A320L43 | 823M30 | 30CND8 | 30CrNiMo8 |

4. Mechanical Property

| Diameter d mm | ≤ 16 | 16-40 | 40-100 | 100-160 | 160-250 |

| Yield Strength Mpa | ≥900 | ≥800 | ≥700 | ≥600 | ≥550 |

| Tensile Strength Mpa | 1100-1300 | 1000-1200 | 900-1100 | 800-950 | 750-900 |

| Elongation, % | ≥10 | ≥11 | ≥12 | ≥13 | ≥14 |

| Reduction of area ,% | ≥45 | ≥50 | ≥55 | ≥60 | ≥60 |

| impact,J | ≥35 | ≥40 | ≥45 | ≥45 | ≥45 |

| Hardness,HB | 331-380 | 298-359 | 271-331 | 240-286 | 225-271 |

5.Forging

Heat the temperature between 1050℃-1150℃,hold suitable time for the steel to be thoroughly heated.Reheat the steel once temperature below 850°C. 30CrNiMo8 steel has good forging characteristics,but crack is easily occured when improper cooling way after forged,so it should be cooled as slowly as possible in the furnace or in sand after forged.

6.Heat Treatment

- Normalizing:870℃-880℃,Cool in air

- Soft Annealing:650℃-700℃,Cooling 10℃ per hour in furnace,max. 248 HB

- Stress Relieving:50°C under the temperature of tempering

- Hardening:830 – 860°C,oil or polymer,840-850°C,water

- Tempering:540°C – 660°C, cool in still air

7.Jominy Test-Hardenability

| HRC-mm | Type | 1.5 | 3 | 6 | 7 | 9 | 11 | 13 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 |

| MIN | +H | 48 | 48 | 48 | 48 | 47 | 47 | 47 | 46 | 46 | 45 | 45 | 44 | 44 | 43 | 43 |

| MAX | 56 | 56 | 56 | 56 | 55 | 55 | 55 | 55 | 55 | 54 | 54 | 54 | 54 | 54 | 54 | |

| MIN | +HH | 51 | 51 | 51 | 51 | 50 | 50 | 50 | 49 | 49 | 48 | 48 | 47 | 47 | 47 | 47 |

| MAX | 56 | 56 | 56 | 56 | 55 | 55 | 55 | 55 | 55 | 54 | 54 | 54 | 54 | 54 | 54 | |

| MIN | +HL | 48 | 48 | 48 | 48 | 47 | 47 | 47 | 46 | 46 | 45 | 45 | 44 | 44 | 43 | 43 |

| MAX | 53 | 53 | 53 | 53 | 52 | 52 | 52 | 52 | 52 | 51 | 51 | 51 | 51 | 50 | 50 |